Hydrophilic nano zinc based composite coating

A composite coating and nano-zinc technology, used in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of metal corrosion weather resistance, difficult weather resistance and adhesion at the same time. Environmental pollution and other problems, to achieve the effect of excellent metal corrosion resistance, strong weather resistance, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

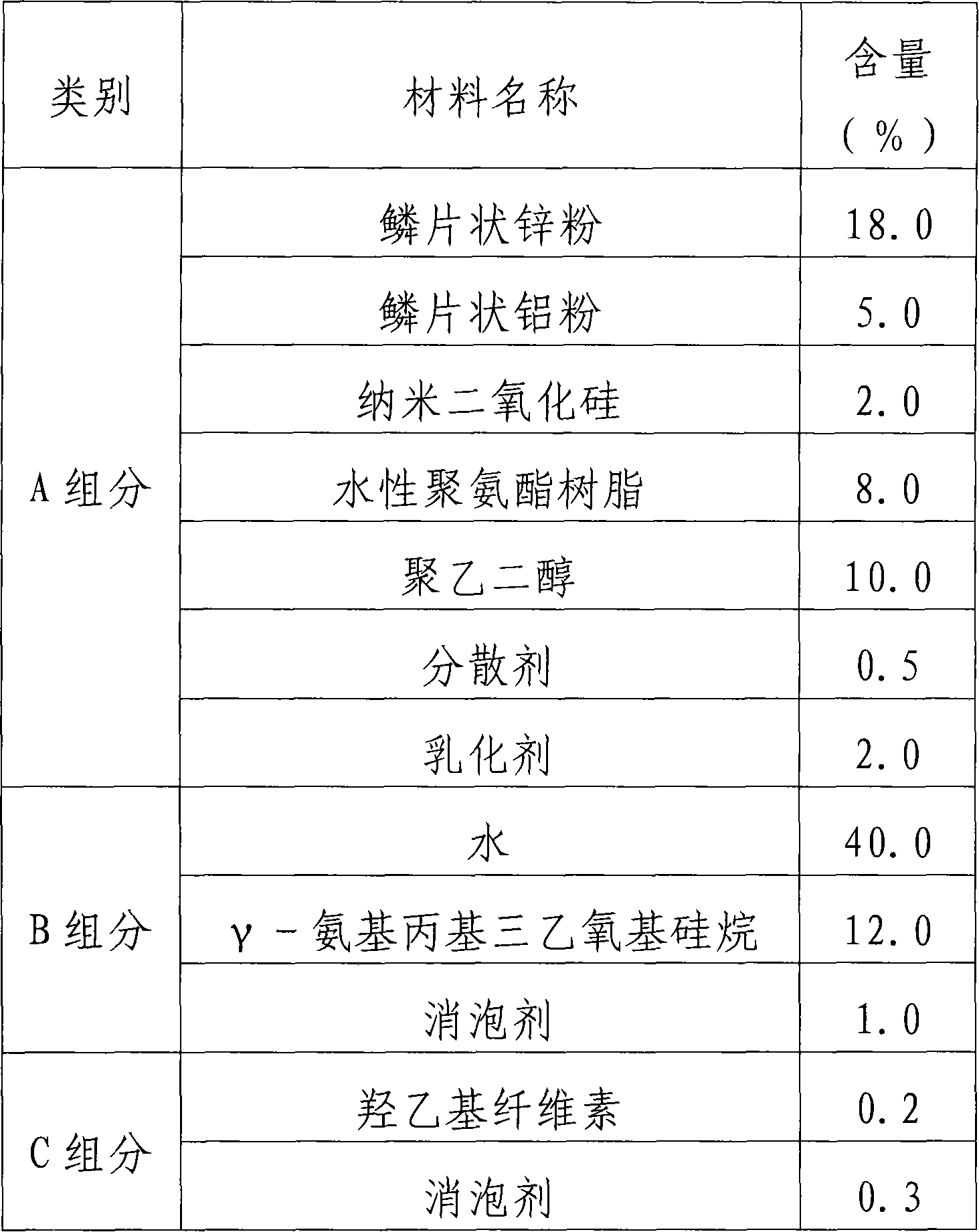

[0019] The parts by weight of each component of water-based nanometer zinc-based composite coating of the present invention are as table 1:

[0020] Table 1

[0021]

[0022] Prepare components A, B, and C according to the formula listed in the table, mix and stir the two components of A and B, then add component C, mix and stir evenly, and pack to obtain the finished water-based nano zinc-based composite coating. In order to prolong the shelf life of the paint, the present invention can also package components A, B and C separately for use. When using, first mix A and B components and stir evenly, then add C component and mix and stir evenly.

[0023] After the coating is applied on the surface of metal parts, it can be baked at a temperature of 100°C-150°C for 5min-30min to form a strong coating. Grade above (tape test).

Embodiment 2

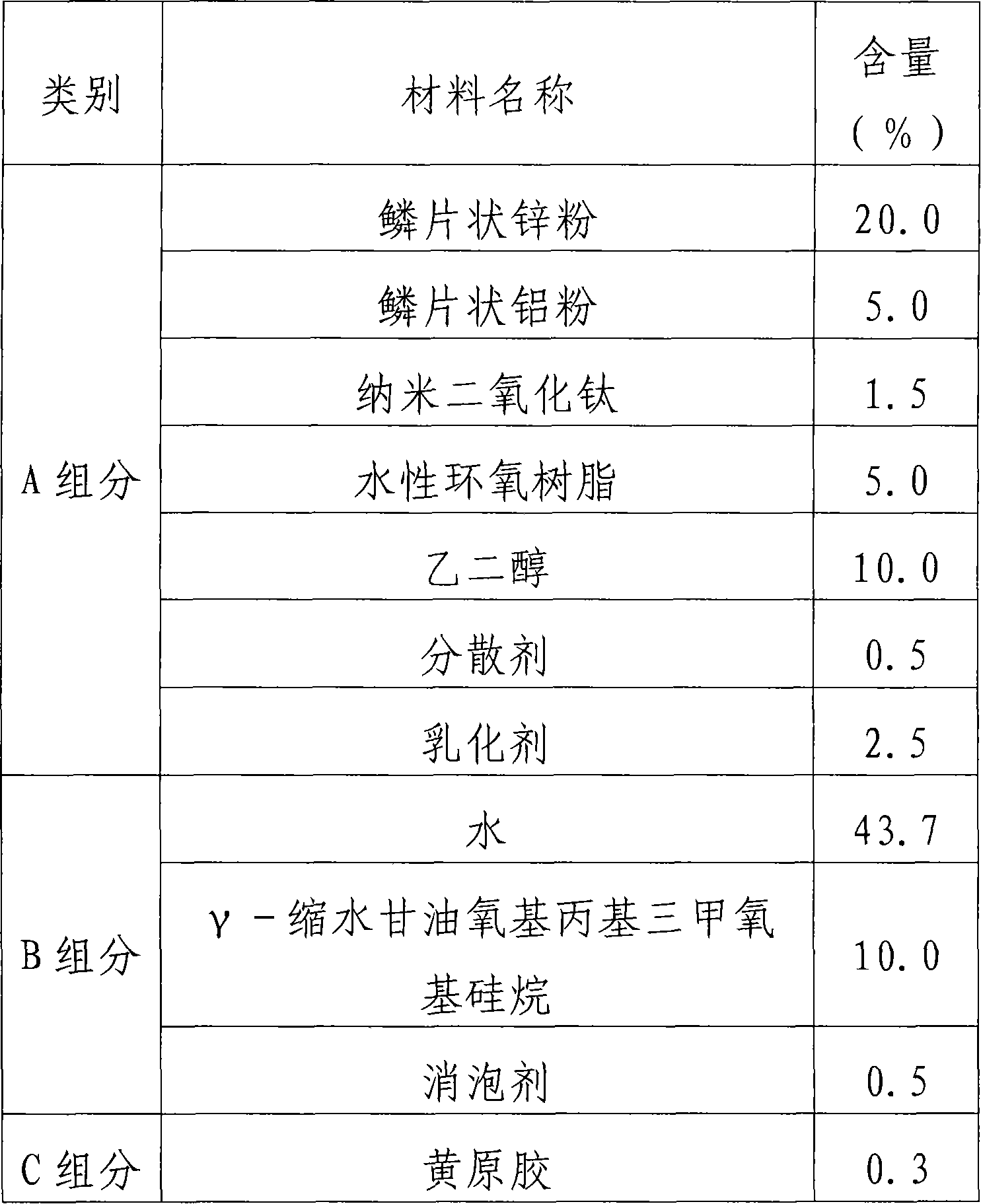

[0025] The parts by weight of each component of the water-based nanometer zinc-based composite paint of the present invention are as shown in Table 2

[0026] Table 2

[0027]

[0028] Prepare components A, B, and C according to the formula listed in the table, mix and stir the two components of A and B, then add component C, mix and stir evenly, and pack to obtain the finished water-based nano zinc-based composite coating. In order to prolong the shelf life of the paint, the present invention can also package components A, B and C separately for use. When using, first mix A and B components and stir evenly, then add C component and mix and stir evenly.

[0029] After the coating is applied on the surface of metal parts, it can be baked at a temperature of 120°C-200°C for 20 minutes to form a strong coating. The coating's neutral salt spray test time can reach more than 800h, and the coating adhesion can reach level 4 or above. (tape test).

Embodiment 3

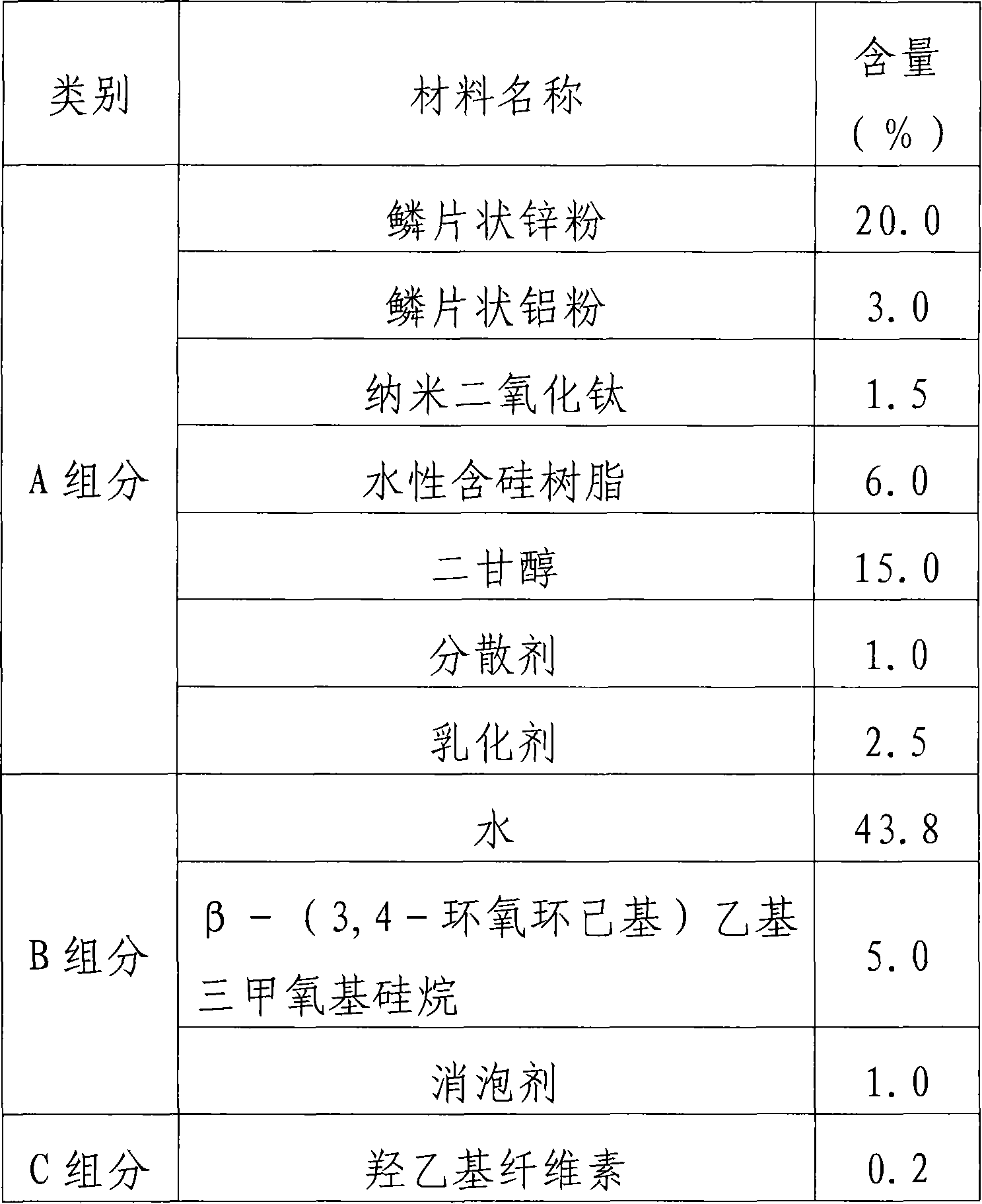

[0031] The parts by weight of each component of the water-based nanometer zinc-based composite coating of the present invention are as table 3

[0032] table 3

[0033]

[0034] Prepare components A, B, and C according to the formula listed in the table, mix and stir the two components of A and B, then add component C, mix and stir evenly, and pack to obtain the finished water-based nano zinc-based composite coating. In order to prolong the shelf life of the paint, the present invention can also package components A, B and C separately for use. When using, first mix A and B components and stir evenly, then add C component and mix and stir evenly.

[0035] After the coating is applied on the surface of metal parts, it can be baked at a temperature of 120°C-250°C for 10min-20min to form a strong coating. Grade above (tape test).

[0036] The technical scheme of the present invention (comprising above-mentioned embodiment) is to facilitate the preparation of B component, he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com