Fluororesin radiating paint and preparation method thereof

A technology of heat-dissipating paint and fluororesin, applied in the direction of coating, can solve the problem of high price, and achieve the effect of increasing emissivity, wide practical value, high thermal conductivity and emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

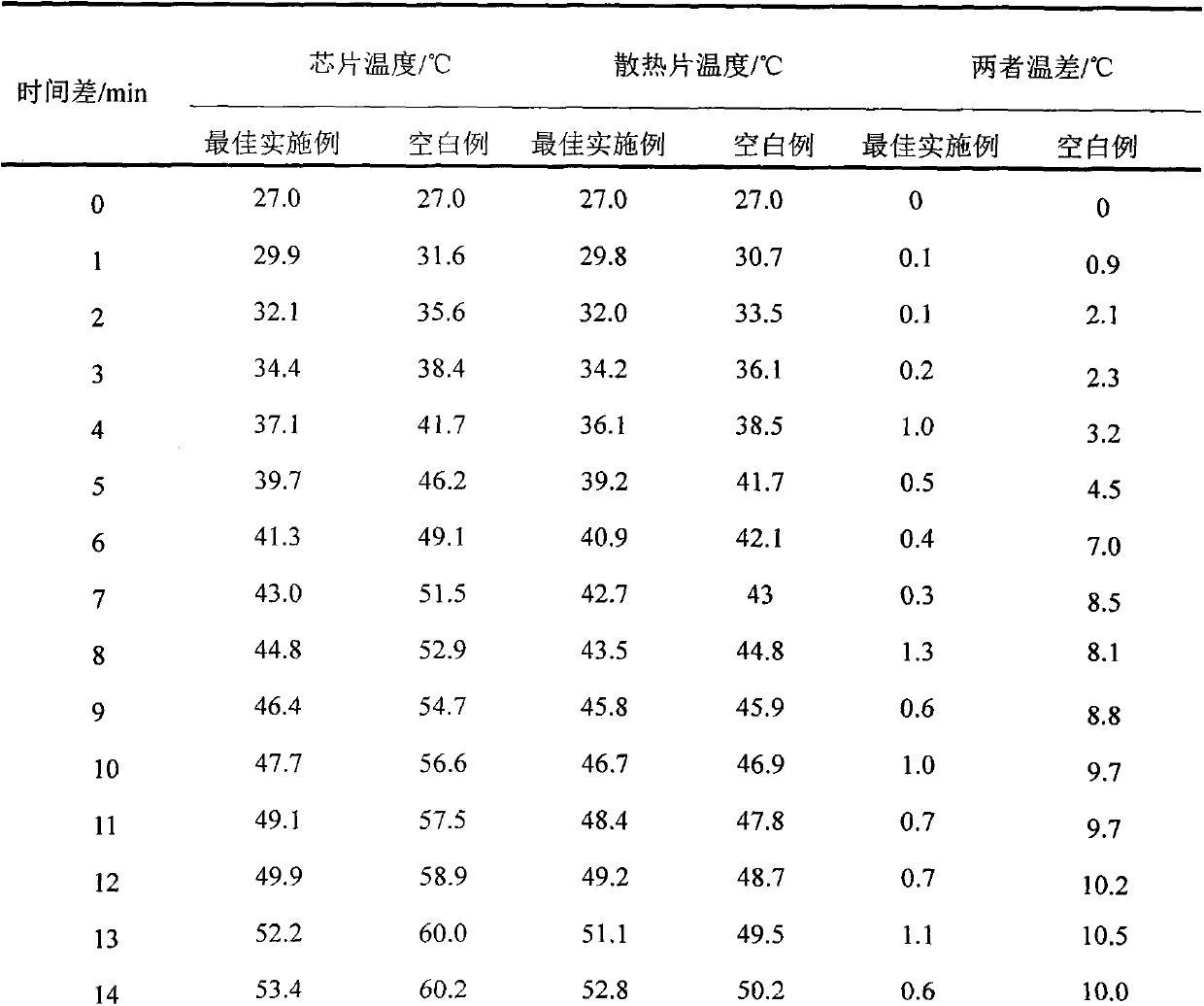

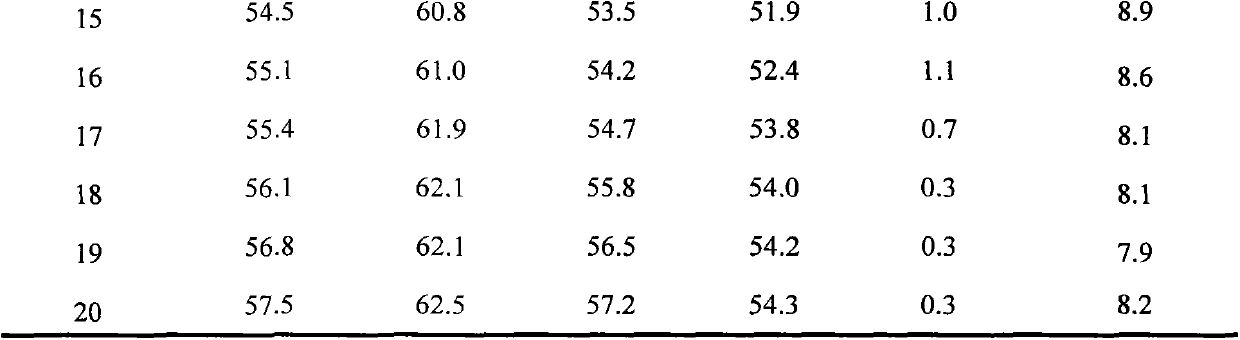

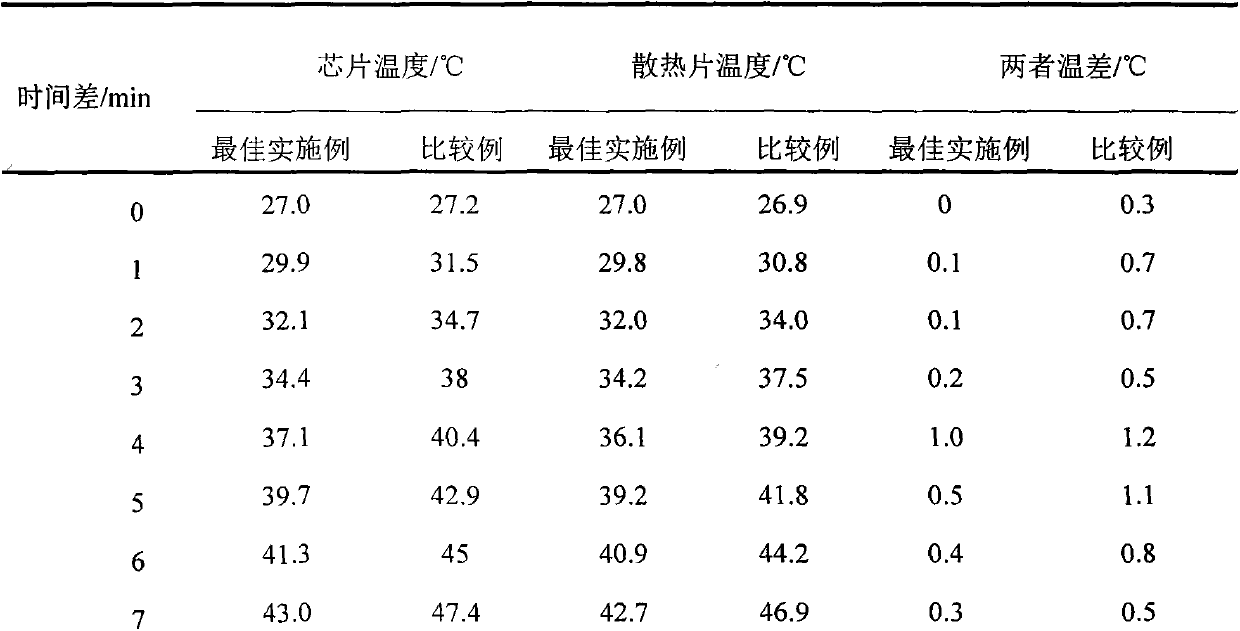

Examples

Embodiment 1

[0048]The following components by weight ratio, 50% fluororesin, 40% special diluent, 4% electron transfer organic compound, 1% graphene, 1% carbon nanotube, 1% titanium dioxide, 3 % of the curing agent is mixed according to the steps and stirred evenly under the condition of 800-1000 rpm at normal temperature to form the target coating. Degrease and decontaminate the surface of the product equipment that needs to be sprayed with heat-dissipating coatings. Stir the target coating fully and pour it into the spray gun. Set the pressure of the spray gun to 0.4MPa, aim at the target surface, and spray back and forth at a distance of 10-20cm. 2-3 times to make the paint evenly cover the surface of the object. The coating is uniform and glossy, and its thickness can be optimized according to needs. The coating can be cured by natural air drying for 12 hours or baked in an oven for 10 minutes to quickly cure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com