Weather-resistant exterior wall paint and preparation method thereof

A technology of exterior wall paint and weather resistance, applied in the field of building materials, can solve the problems of high cost of nano materials, fading of coatings, loss of light, etc., and achieve the effect of solving fading and excellent anti-ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

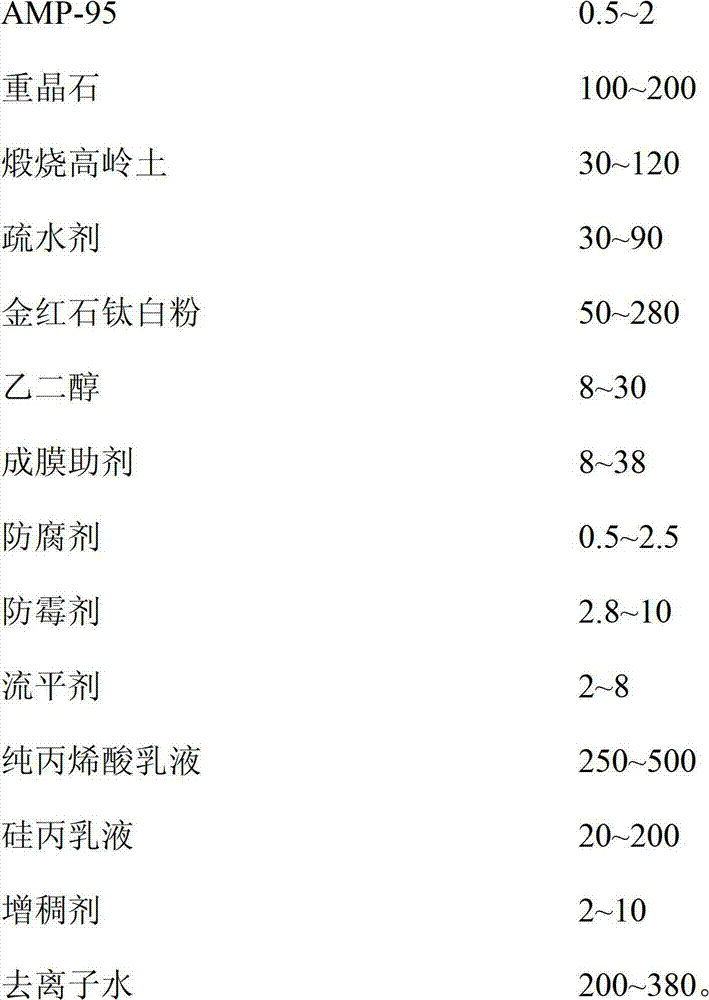

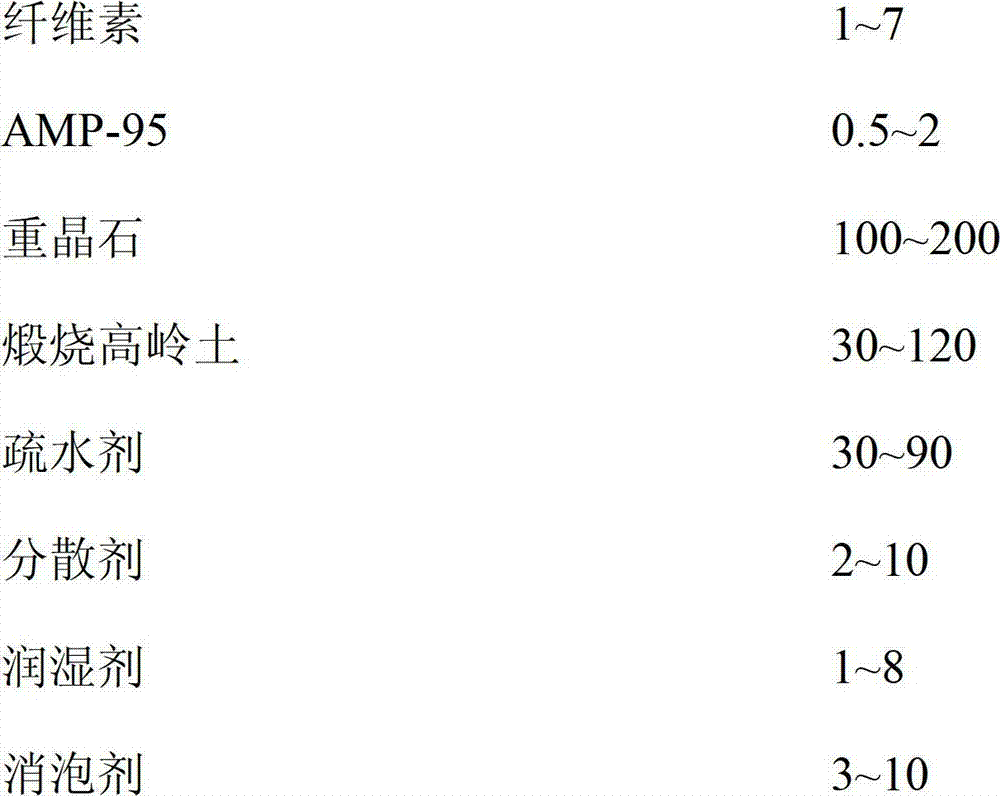

[0073] A weather-resistant exterior wall paint comprising the following components in parts by weight:

[0074] Cellulose acetate butyrate 1, AMP-95 (Nanjing Gutian Chemical Co., Ltd.) 2, barite (Baixin Quartz Sand Processing Plant, Lingshou County, Hebei Province) 100, calcined kaolin (Fengye Kaolin Co., Ltd.) 120, lotus leaf hydrophobic Agent AS-CP40530, rutile titanium dioxide 50, ethylene glycol 30, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 38, Kathon preservative KF-882.5, Nordes EPW Paint film antifungal agent 2.8, GSK-588 series leveling agent 8, pure acrylic emulsion (BASF) 500, silicon acrylic emulsion (BASF) 20, ASE-60 thickener (Rohm and Haas) 10, deionized water 200.

[0075] The preparation method of described weather-resistant exterior wall paint is as follows:

[0076] (1) Weigh 190 parts by weight of deionized water and put it into the reactor, then start the high-speed disperser and control the speed at 300r / min;

[0077] (2) Weigh the formulated amou...

Embodiment 2

[0084] A weather-resistant exterior wall paint comprising the following components in parts by weight:

[0085] Hydroxyethyl cellulose 2, ethyl cellulose 5, AMP-95 (Nanjing Gutian Chemical Co., Ltd.) 0.5, barite (Baixin Quartz Sand Processing Plant, Lingshou County, Hebei) 200, calcined kaolin (Fengye Kaolin Co., Ltd. ) 30, rutile titanium dioxide 280, lotus leaf hydrophobic agent AS-CW30690, ethylene glycol 8, diethylene glycol butyl ether 3, dipropylene glycol methyl ether 5, Cathone preservative MIT 0.5, antifungal agent OBPA (Shandong Ai General Chemical Co., Ltd.) 10. Polyurethane aqueous solution 2. Pure acrylic emulsion (BASF) 250. Silicone acrylic emulsion (BASF) 200. DR-72 thickener (Rohm and Haas) 2. Deionized water 380.

[0086] The preparation method of described weather-resistant exterior wall paint is as follows:

[0087] (1) Weigh 300 parts by weight of deionized water and put it into the reactor, then start the high-speed disperser and control the speed at 500...

Embodiment 3

[0095] A weather-resistant exterior wall paint comprising the following components in parts by weight:

[0096] Methylcellulose 5.9, AMP-95 (Nanjing Gutian Chemical Co., Ltd.) 0.9, barite (Baixin Quartz Sand Processing Plant, Lingshou County, Hebei Province) 180, calcined kaolin (Fengye Kaolin Co., Ltd.) 60, AS-CW30653, Sodium salt dispersant (Zhengyuan Chemical JD-5040) 2, AES 3, AEO-75, 4200 defoamer (BASF) 3, rutile titanium dioxide 150, ethylene glycol 18, diethylene glycol butyl ether 10, 2,2 , 4-trimethyl-1,3-pentanediol monoisobutyrate 18, benzoic acid 1.3, organic iodine 7.8, polyurethane aqueous solution 5, pure acrylic emulsion (BASF) 350, silicon acrylic emulsion (BASF) 120, hydroxyl Ethyl cellulose 6, deionized water 330.

[0097] The preparation method of described weather-resistant exterior wall paint is as follows:

[0098] (1) Weigh 230 parts by weight of deionized water and put it into the reactor, then start the high-speed disperser and control the speed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com