Hollow ceramic insulation board for coal gangues and construction wastes and manufacturing method thereof

A technology for construction waste and hollow ceramics, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as immature technology, and achieve the effects of strong weather resistance, high strength and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

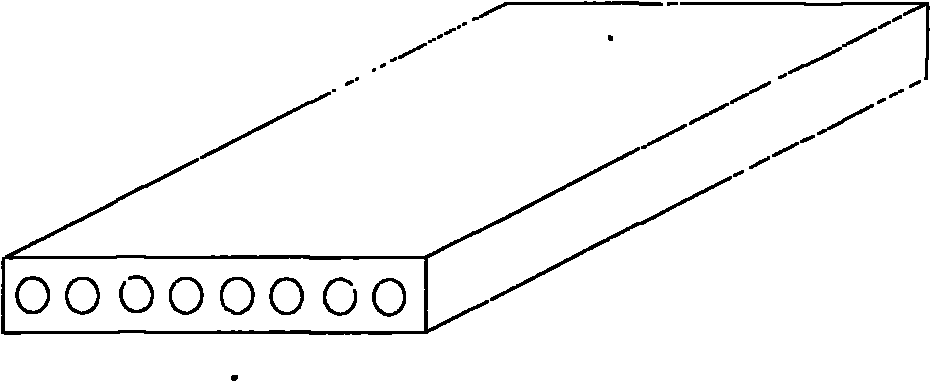

[0024] The raw material formula is as follows: coal gangue 60%, construction waste 15%, shale 15%, tailing slag 10%.

[0025] According to the above ratio, grind it to 80 mesh, add 17% water and stir it; stale for 36 hours, use an extrusion molding machine to extrude it into a thin plate with a middle hole; dry it; put it into a kiln and burn it at 1150°C That's it.

Embodiment 2

[0027] The raw material formula is as follows: coal gangue 70%, construction waste 20%, shale 5%, tailings slag 5%.

[0028] According to the above proportions, grind it to 40 mesh, add 18% water and stir; stale for 48 hours, use an extrusion molding machine to extrude it into a thin plate with a middle hole; dry it; put it into a kiln and burn it at 1180°C That's it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com