POSS and silicone oil modified fluorinated acrylate building waterproof paint

An acrylic and architectural waterproofing technology, applied in the direction of coating, etc., can solve the problems of loss of waterproofing effect, poor adhesion, weak force, etc., and achieve the effect of good waterproof performance, strong adhesion, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

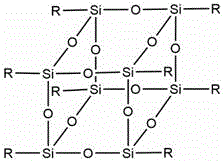

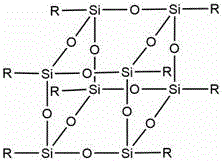

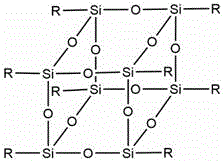

Image

Examples

Embodiment 1

[0043] 5 parts by mass of hexafluorobutyl methacrylate and 0.1 parts by mass of benzoyl peroxide were added to 85 parts by mass of ethanol to obtain solution A; 2 parts by mass of allyl POSS, 5 parts by mass of hexafluorobutyl methacrylate Esters, 0.1 mass parts molecular weight is about 0.5*10 3Vinyl-terminated silicone oil (vinyl content is about 10%) and 2.8 parts by mass of vinyltriethoxysilane were mixed uniformly to obtain solution B; solution A was heated to 80°C under stirring, and after 1 hour of reaction, within half an hour Add solution B dropwise to solution A, continue to stir and react for 2 h, and then cool down to obtain a waterproof coating for construction engineering.

Embodiment 2

[0045] Add 10 parts by mass of hexafluorobutyl acrylate, 3 parts by mass of butyl methacrylate and 1 part by mass of azobisisobutyronitrile into 60 parts by mass of ethanol to obtain solution A; add 5 parts by mass of vinyl POSS, 10 parts by mass of 3 parts by mass of hexafluorobutyl acrylate, 3 parts by mass of butyl methacrylate, 3 parts by mass of vinyl triethoxysilane and 5 parts by mass of 3 Mix vinyl-terminated silicone oil evenly to obtain solution B; raise the temperature of solution A to 80°C under stirring, and after reacting for 1 hour, add solution B dropwise to solution A within half an hour, continue to stir and react for 2 hours, and then cool down to obtain Construction engineering waterproof coating.

Embodiment 3

[0047] Add 14.5 parts by mass of dodecafluoroheptyl acrylate and 0.5 parts by mass of azobisisobutyronitrile into 65 parts by mass of butanol to obtain solution A; add 4 parts by mass of methacryloxypropyl POSS, 14.5 parts by mass of acrylic acid Dodecafluoroheptyl ester, 0.5 parts by mass of methacryloxypropyltrimethoxysilane and 1 part by mass of molecular weight 1.0*10 4 Vinyl-terminated silicone oil (vinyl content about 0.5%) was mixed evenly to obtain solution B; solution A was heated to 80°C under stirring, and after 1 hour of reaction, solution B was added dropwise to solution A within half an hour, and continued After stirring and reacting for 2 hours, the temperature was lowered to obtain a waterproof coating for construction engineering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com