Ultraviolet-curing pressure-sensitive composition and pressure-sensitive adhesive

A composition and curing pressure technology, applied in the direction of pressure-sensitive film/sheet, adhesive, adhesive type, etc., can solve the problems of good weather resistance, good bonding adaptability, no pollution, etc., to achieve improved bonding performance, Strong weather resistance, no yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below in conjunction with examples.

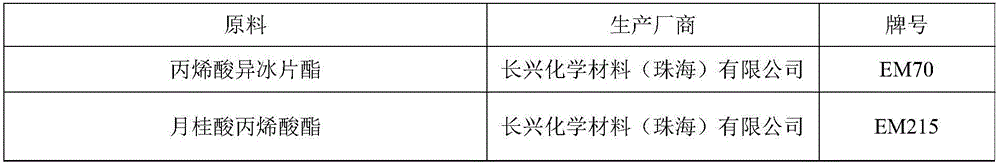

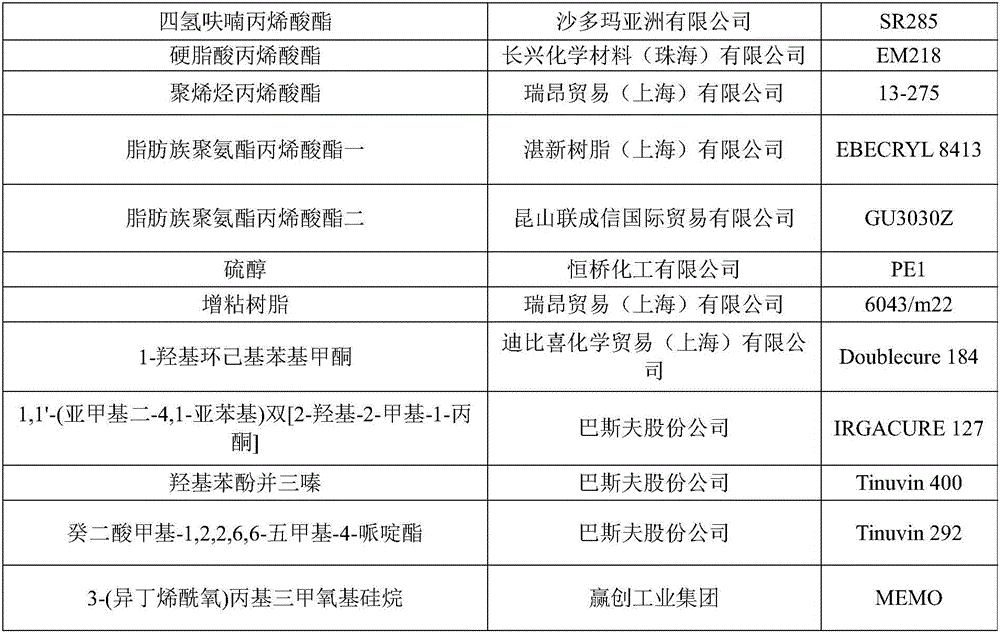

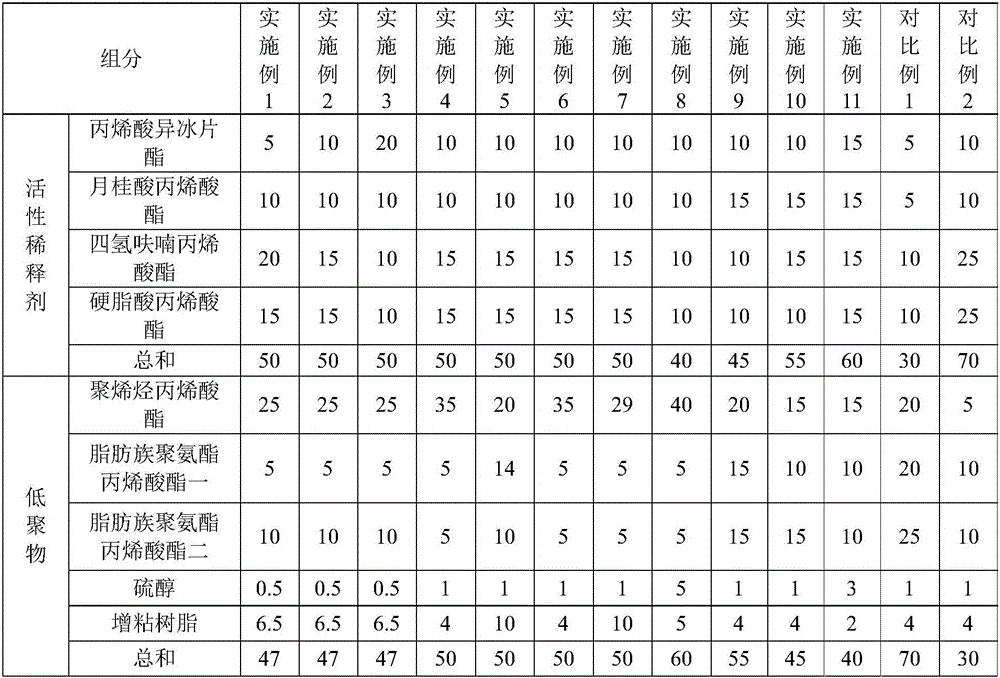

[0025] As described in the background technology, the UV-curable pressure-sensitive adhesives in the prior art cannot simultaneously have no pollution, good bonding adaptability, good weather resistance and high light transmittance, which greatly limits its application in optical equipment. Application, in order to solve the above problems, in a typical embodiment of the present application, a UV-curable pressure-sensitive composition is provided, including an oligomer, a reactive diluent and a photoinitiator, wherein the reactive diluent and the oligomer The weight ratio of the compound is 40:60-60:40, the weight content of the photoinitiator in the composition is 1-5%, and in parts by weight, the oligomer includes: 20-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com