Aqueous inorganic zinc-rich prime coat and preparation method thereof

An inorganic zinc-rich primer technology, applied in the direction of anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of porous coatings, poor impact resistance, poor weather resistance of coatings, etc., to achieve strong adhesion, The effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of water-based inorganic zinc-rich primer of the present invention comprises the following steps:

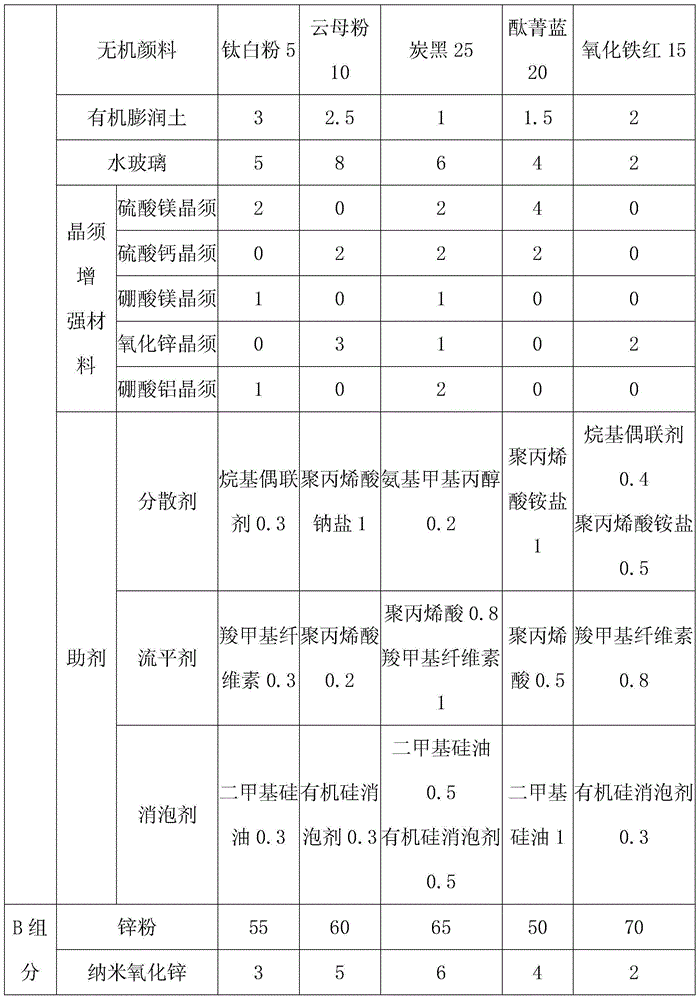

[0028] (1) Preparation of component A: first mix alkali metal silicate, aluminum-modified silica sol, partially deionized water, water glass, and additives thoroughly; then add the above-mentioned inorganic pigments, organic bentonite, and whisker reinforcement The material and all the other deionized water are fully mixed, and the gained liquid is passed through a 70 mesh sieve to obtain the A component of the water-based inorganic zinc-rich primer of the present invention;

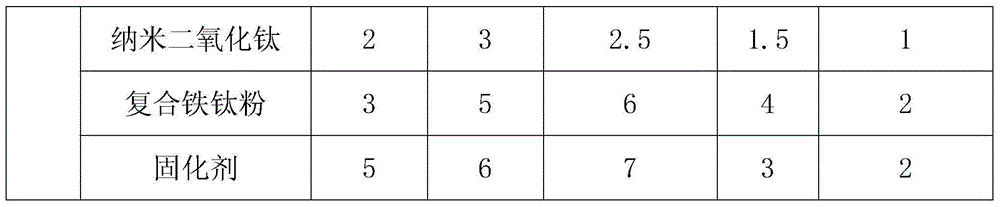

[0029] (2) Preparation of component B: fully mix zinc powder, nano-zinc oxide, nano-titanium dioxide, composite iron-titanium powder, and curing agent to obtain component B of the water-based inorganic zinc-rich primer of the present invention;

[0030] The particle size of organic bentonite is 300-400 mesh.

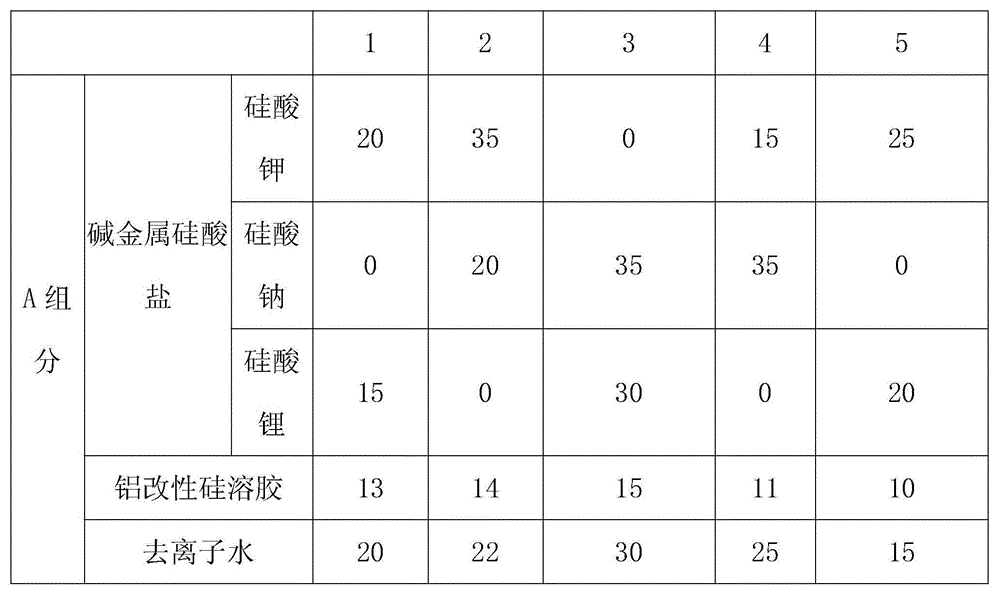

[0031] The proportioning ratio of each raw material in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com