Dry-method preparing method for polyurethane micro-porous film

A technology of microporous membrane and polyurethane, which is applied in the field of microporous membrane, can solve the problems that the air permeability cannot be improved, the dry coating feels hard, and the processing technology is complicated, etc., and achieves low production cost, good moisture permeability and waterproof performance, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

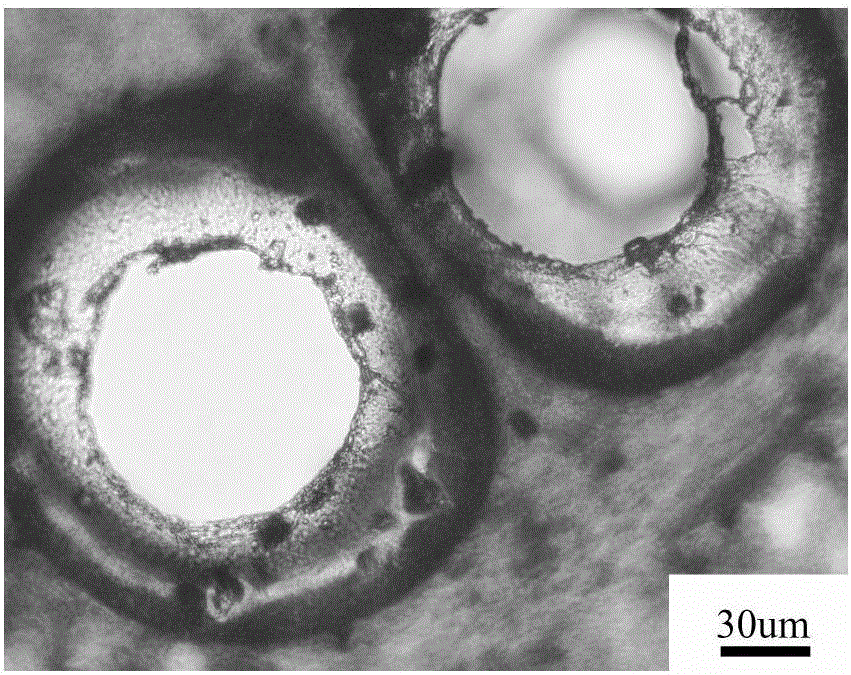

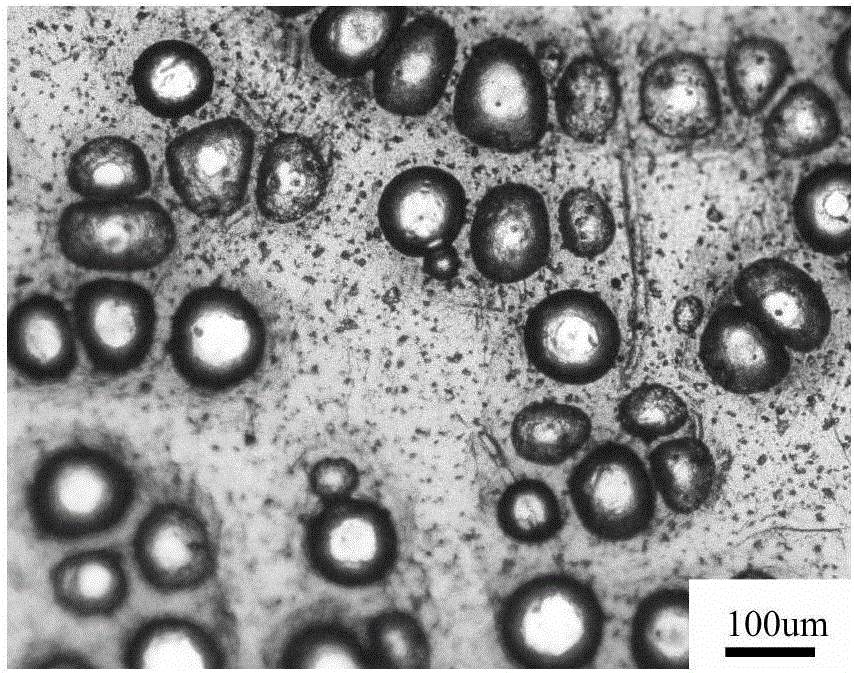

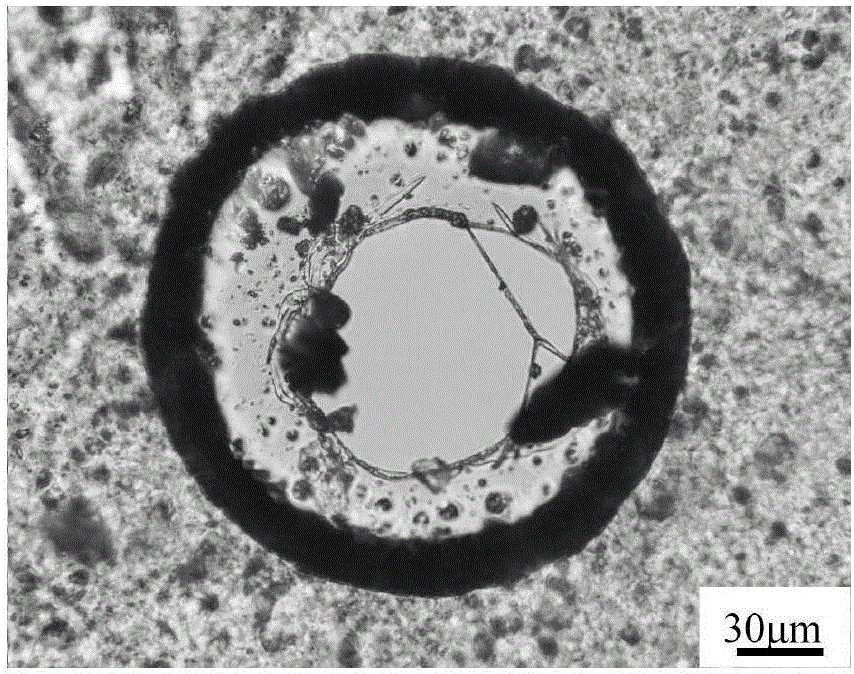

Image

Examples

Embodiment 1

[0030] The microporous membrane includes:

[0031] 20 parts of polyether polyurethane resin, 79 parts of solvent DMF, 0.6 parts of AC foaming agent, 0.4 parts of catalytic assistant ZnO;

[0032] The parts of the above components are all parts by mass, and the mass units used in each step are the same. (The following examples are the same)

[0033] The polyether polyurethane resin is PU888 of Luoyang Jiming Chemical Co., Ltd.;

[0034] The solvent is Tianjin Fuchen Chemical Reagent Factory DMF;

[0035] The blowing agent is AC blowing agent of Jiangyin Moore Chemical New Material Co., Ltd.;

[0036] The catalytic promoter is ZnO from Tianjin Fuchen Chemical Reagent Factory;

[0037] The said release paper is a flat release paper, specifically a silicone release paper.

[0038] Correspondingly, the present invention also provides a method for preparing a waterproof and moisture-permeable polyurethane microporous membrane, which includes the following steps:

[0039] S1: Mix the resin with 7...

Embodiment 2

[0044] The microporous membrane includes:

[0045] 25 parts of polyether polyurethane resin, 73 parts of solvent DMF, 1 part of AC blowing agent, 1 part of catalytic assistant ZnO;

[0046] The parts of the above components are all parts by mass, and the mass units used in each step are the same.

[0047] The polyether polyurethane resin is PU-K20 of Luoyang Jiming Chemical Co., Ltd.;

[0048] The solvent is Tianjin Fuchen Chemical Reagent Factory DMF;

[0049] The blowing agent is AC blowing agent of Jiangyin Moore Chemical New Material Co., Ltd.;

[0050] The catalytic promoter is ZnO from Tianjin Fuchen Chemical Reagent Factory;

[0051] The said release paper is a flat release paper, specifically a silicone release paper.

[0052] Correspondingly, the present invention also provides a method for preparing a waterproof and moisture-permeable polyurethane microporous membrane, which includes the following steps:

[0053] S1: Mix the resin with 70.8 parts of solvent and stir for 25 minutes...

Embodiment 3

[0058] The microporous membrane includes:

[0059] 20 parts of polyether polyurethane resin, 79.7 parts of solvent DMF, 0.2 part of AC blowing agent, 0.1 part of catalytic assistant ZnO;

[0060] The parts of the above components are all parts by mass, and the mass units used in each step are the same.

[0061] The polyether polyurethane resin is PU128 of Luoyang Jiming Chemical Co., Ltd.;

[0062] The solvent is Tianjin Fuchen Chemical Reagent Factory DMF;

[0063] The blowing agent is AC blowing agent of Jiangyin Moore Chemical New Material Co., Ltd.;

[0064] The catalytic promoter is ZnO from Tianjin Fuchen Chemical Reagent Factory;

[0065] The said release paper is a flat release paper, specifically a silicone release paper.

[0066] Correspondingly, the present invention also provides a method for preparing a waterproof and moisture-permeable polyurethane microporous membrane, which includes the following steps:

[0067] S1: Mix the resin with 79.4 parts of solvent and stir for 22 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com