Wear-resistant carbon fiber coating and coating method thereof

A carbon fiber, anti-wear technology, applied in coatings, anti-corrosion coatings, polyamide coatings, etc., can solve the problems of large particles of coating materials, poor wear resistance, poor chemical corrosion resistance, etc., to delay the entry into the coating Excellent speed, good chemical corrosion resistance, and remarkable anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

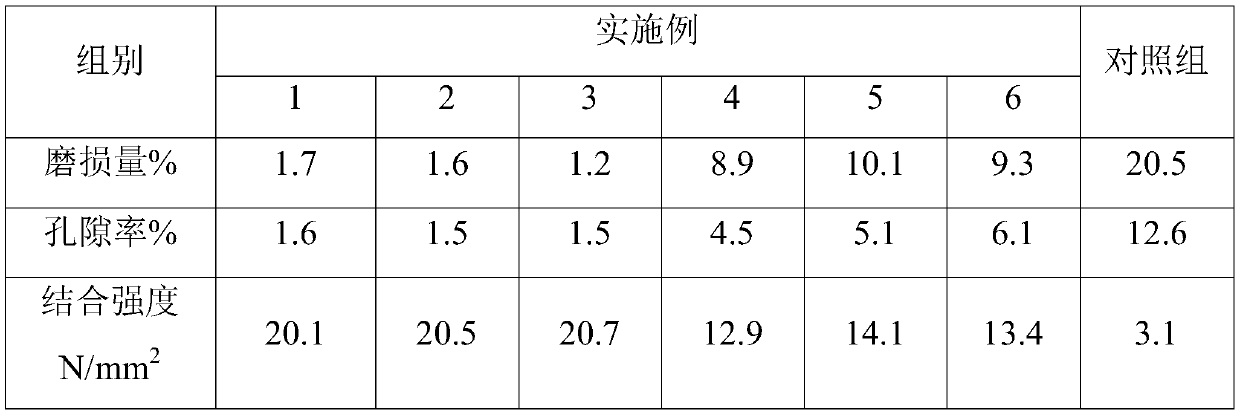

Examples

preparation example Construction

[0026] (3) preparation of coating material,

[0027] Specifically: choose and weigh raw materials, mix and melt epoxy resin, solvent, adhesive, clay, and anti-corrosion fillers, control the temperature at 100-120°C, evenly put silicon dioxide into the raw materials in a mixed and molten state, and grind them in a ball mill Grind for 2-3 hours, set the speed of the ball mill at 2000-3000r / min, add curing agent, transfer to a high-speed disperser, set the speed at 3500-5000r / min, and disperse for 25-40min, so that the coating material Fully form a homogenate, and keep the obtained coating material at 75-90°C for standby;

[0028] (4) Coating and curing methods of the coating;

[0029] Specifically: use a spray gun to spray the prepared coating material on the dry carbon fiber, control the thickness of the first layer of coating at 15-30 μm, irradiate for 20-30 minutes under the action of ultraviolet rays after coating, and carry out the second coating. Spraying of the second-l...

Embodiment 1

[0034] An anti-wear carbon fiber coating comprises the following components by weight: 35 parts of resin, 15 parts of solvent, 10 parts of binder, 4 parts of clay, 18 parts of silicon dioxide, 10 parts of filler, and 8 parts of curing agent.

[0035] The resin is epoxy resin; the solvent is composed of acetone and water in a ratio of 8:1; the adhesive is polyethersulfone; the clay is bentonite; The layer structure material is a nano-graphene material; the curing agent is composed of polyamide and methyl hexahydrophthalic anhydride in a ratio of 1:1.

[0036] In addition, a coating method of an anti-wear carbon fiber coating is provided, comprising the steps of:

[0037] (1) Add absolute ethanol to the carbon fiber, wash it once under ultrasonic conditions for 20 minutes, filter, add acetone again to continue washing for 1 hour, filter, add distilled water and continue washing for 20 minutes;

[0038] (2) Place the cleaned carbon fiber under a vacuum condition of 75° C., and d...

Embodiment 2

[0044] An anti-wear carbon fiber coating comprises the following components by weight: 45 parts of resin, 10 parts of solvent, 10 parts of binder, 4 parts of clay, 10 parts of silicon dioxide, 10 parts of filler and 11 parts of curing agent.

[0045] The resin is phenolic resin; the solvent is composed of acetone and water in a ratio of 12:5; the binder is polyethersulfone; the clay is montmorillonite; the filler is spherical The structural material is porous powdered quartz; the curing agent is composed of polyamide and methyl hexahydrophthalic anhydride in a ratio of 5:2.

[0046] In addition, a coating method of an anti-wear carbon fiber coating is provided, comprising the steps of:

[0047] (1) Add absolute ethanol to the carbon fiber, wash it once under ultrasonic conditions for 30 minutes, filter, add acetone again to continue washing for 2 hours, filter, add distilled water and continue washing for 30 minutes;

[0048] (2) Place the cleaned carbon fiber under a vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com