Method for preparing high-strength fired bricks through adoption of diatomite

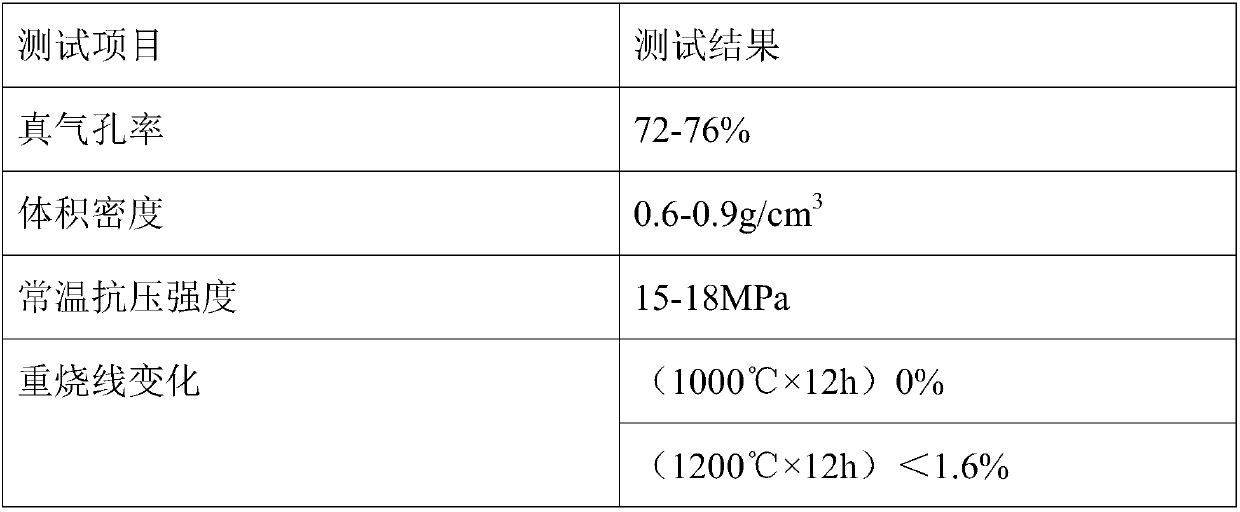

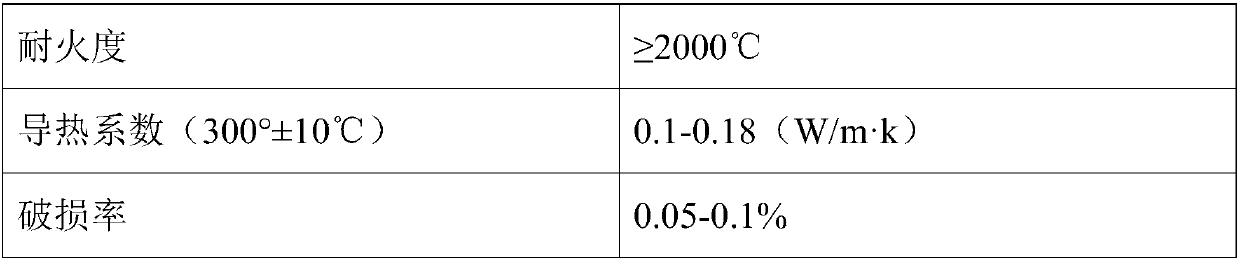

A diatomite, high-strength technology, applied in the field of sintered bricks, can solve the problems of easy cracking, poor shrinkage resistance, and heavy sintered bricks, and achieves the effects of strong dispersion ability, low breakage rate, and good thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing high-strength sintered bricks by using diatomite, comprising the steps of:

[0022] (1) Mix waste brick powder, diatomaceous earth, polystyrene particles, and water, stir at a temperature of 92°C, and filter with plates and frames to obtain wet materials;

[0023] (2) Mix polyethylene wax, carbonized bagasse, montmorillonite, and ammonium persulfate evenly, adjust the temperature to 131°C, add acrylic acid, stir, add water and mix evenly, adjust the system to be alkaline with sodium hydroxide, and send it into Grind evenly in a crucible, send it into a carbonization furnace, heat up to 265°C under nitrogen protection, keep it warm, cool down to room temperature, and pulverize to obtain a montmorillonite composite;

[0024] (3) Add montmorillonite compound, alkali slag, red mud, and iron ore tailings to the wet material, mix evenly, press into bricks, dry, and sinter to obtain high-strength sintered bricks.

Embodiment 2

[0026] A method for preparing high-strength sintered bricks by using diatomite, comprising the steps of:

[0027] (1) Mix 30 parts of waste brick powder, 25 parts of diatomaceous earth, 5 parts of polystyrene particles and 140 parts of water in parts by weight, stir at 85° C. for 2 hours, and filter with plate and frame to obtain wet material;

[0028] The thermal conductivity of the polystyrene particles is 0.02w / m.k, the tensile strength is 67MPa, and the heat capacity is 1.15kJ / (kg·K);

[0029] (2) Mix 80 parts of polyethylene wax, 5 parts of carbonized bagasse, 18 parts of montmorillonite, and 0.1 part of ammonium persulfate in parts by weight, adjust the temperature to 135°C, add 2 parts of acrylic acid, stir for 4 hours, and add 200 parts Mix water evenly, adjust the pH of the system to 7.5 with sodium hydroxide, send it into a crucible, grind it evenly, send it into a carbonization furnace, raise the temperature to 240°C for 25 minutes under the protection of nitrogen, ...

Embodiment 3

[0033] A method for preparing high-strength sintered bricks by using diatomite, comprising the steps of:

[0034] (1) Mix 60 parts of waste brick powder, 15 parts of diatomaceous earth, 12 parts of polystyrene particles and 100 parts of water by weight, stir at 98°C for 1 hour, and filter with plate and frame to obtain wet material;

[0035] The thermal conductivity of the polystyrene particles is 0.04w / m.k, the tensile strength is 62MPa, and the heat capacity is 1.25kJ / (kg·K);

[0036] (2) Mix 50 parts of polyethylene wax, 14 parts of carbonized bagasse, 10 parts of montmorillonite, and 0.2 parts of ammonium persulfate in parts by weight, adjust the temperature to 125°C, add 6 parts of acrylic acid, stir for 2 hours, and add 400 parts Mix water evenly, use sodium hydroxide to adjust the pH of the system to 7.2, put it into a crucible, grind it evenly, put it into a carbonization furnace, raise the temperature to 270°C for 15 minutes under the protection of nitrogen, cool down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com