Automatic constant-linear-speed control system of film applicator

An automatic control system and constant linear velocity technology, applied in the direction of digital control, electrical program control, textile processing machine accessories, etc., can solve problems such as difficult to achieve constant linear velocity, and achieve the effect of reducing labor intensity and uniform longitudinal thickness of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

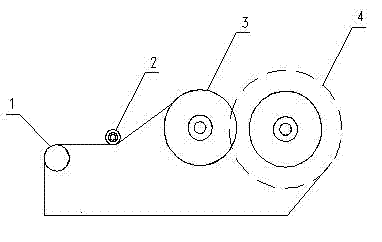

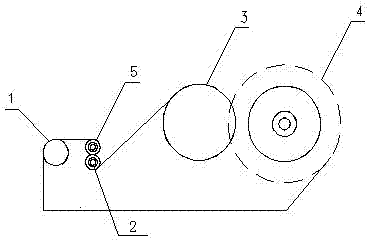

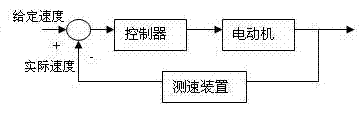

[0011] The structure and control principle of the constant linear speed automatic control system of the film scraping machine of the present invention are shown in Figure 1-Figure 3 As shown, the motor is connected to the reel of the cloth receiving roller 4, the cloth releasing roller 3 is installed on the front of the cloth receiving roller 4, the auxiliary roller 2 is installed between the cloth releasing roller 3 and the scraping roller 1, and the speed detection roller 5 is installed above the auxiliary roller 2. A speed detection device is installed on the speed detection roller 5, and the speed detected by the speed detection device is compared with a given speed to form a closed-loop control through a frequency converter connected to a motor.

[0012] This system adopts the method of direct transmission of the reel (that is, the reel is directly driven by the motor). During the winding process, the winding speed v is required to be a constant value. This requires that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com