Corrosion inhibitor film applicator for gathering and transportation pipelines

A film applicator and pipeline technology, applied in the direction of coating, pipe components, pipes/pipe joints/pipe fittings, etc., can solve problems such as difficult rotation, high frictional resistance, and failure to receive sprayed liquid, etc., to reduce top corrosion The effect of speed, guaranteed coating time, and guaranteed coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

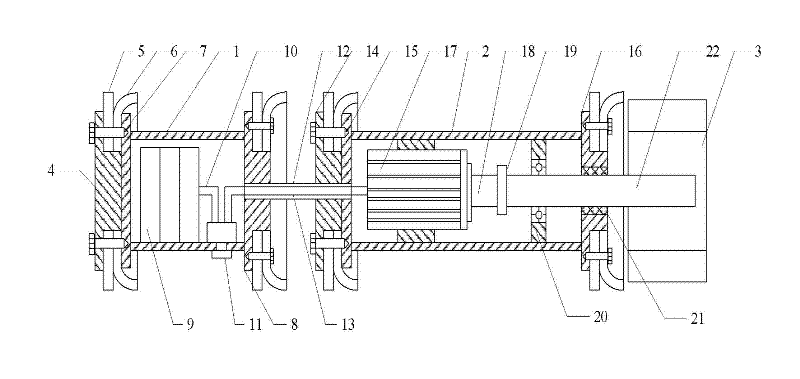

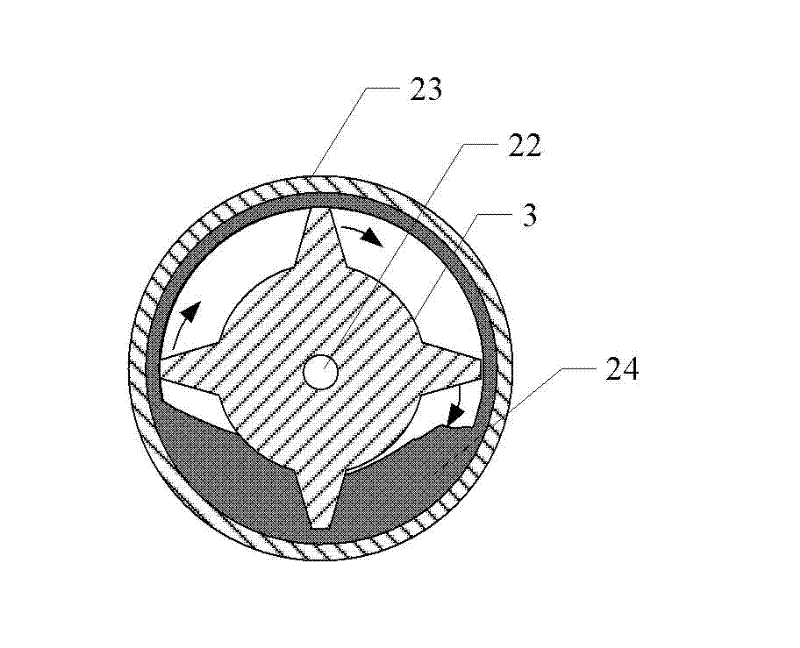

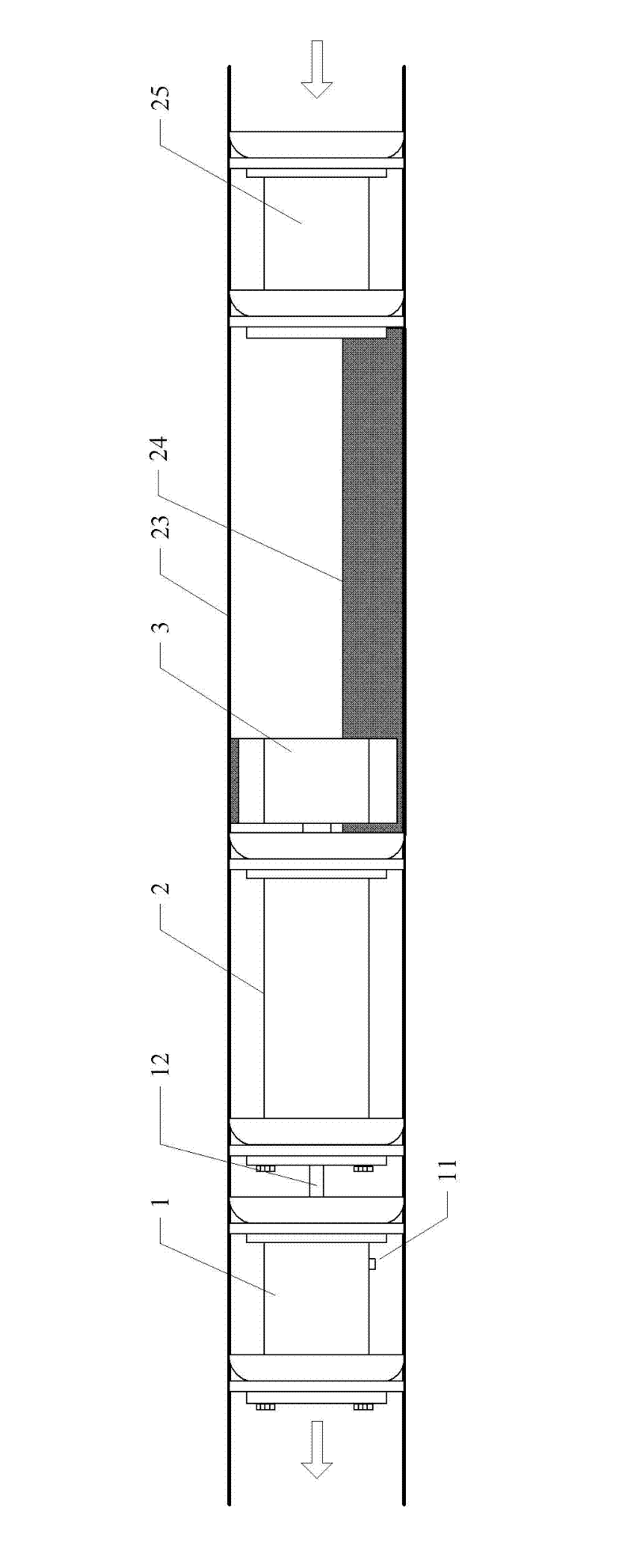

[0011] Depend on figure 1 It can be seen that the present invention is composed of battery compartment 1, motor compartment 2, and impeller 3. The battery compartment 1 and the motor compartment 2 are tubular bodies, and both ends are equipped with guide discs 5 and sealing cups 6, which are fixed on the front and rear by bolts. On the end plate, a battery pack 9 and a governor 11 are installed in the battery compartment 1, and the two are connected by a battery wire 10; the battery compartment 1 and the motor compartment 2 are connected through a universal joint 12, and the speed regulating wire 13 is arranged In the joint 12, the governor 11 is connected with the motor 17 in the motor compartment 2, and the rotating shaft 22 of the motor 17 is connected with the impeller 3.

[0012] The front end of the battery compartment 1 is equipped with a guide plate 5 and a sealing cup 6, which are located between the front pressure plate 4 of the battery compartment 1 and the front co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com