Patents

Literature

38 results about "Volumetric density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

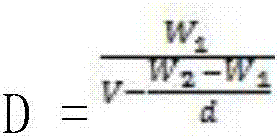

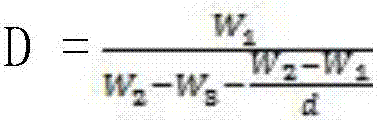

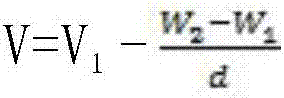

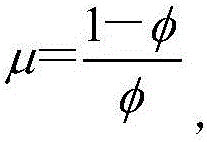

The density, or more precisely, the volumetric mass density, of a substance is its mass per unit volume. The symbol most often used for density is ρ (the lower case Greek letter rho ), although the Latin letter D can also be used. Mathematically, density is defined as mass divided by volume: where ρ is the density, m is the mass, and V is the volume.

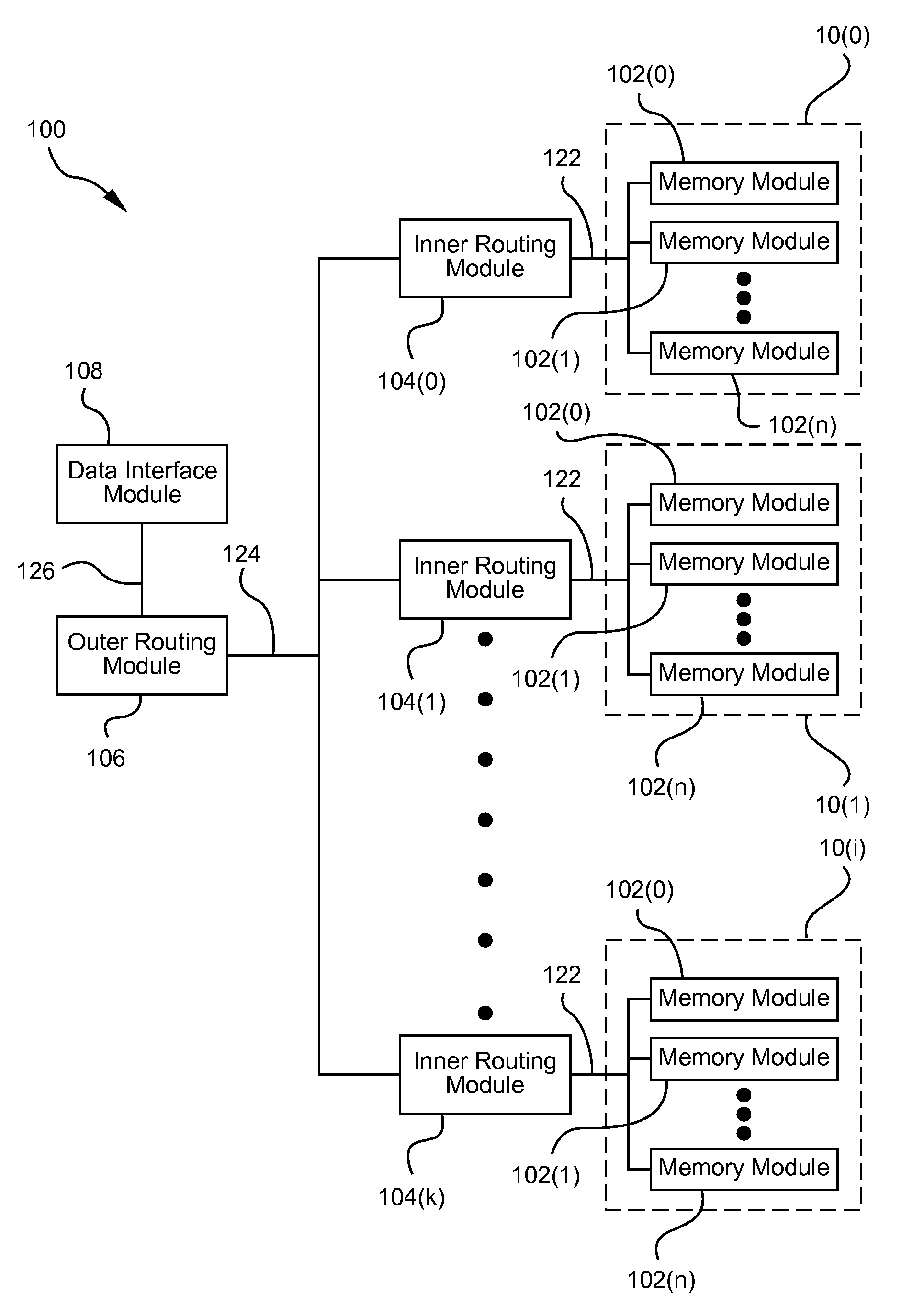

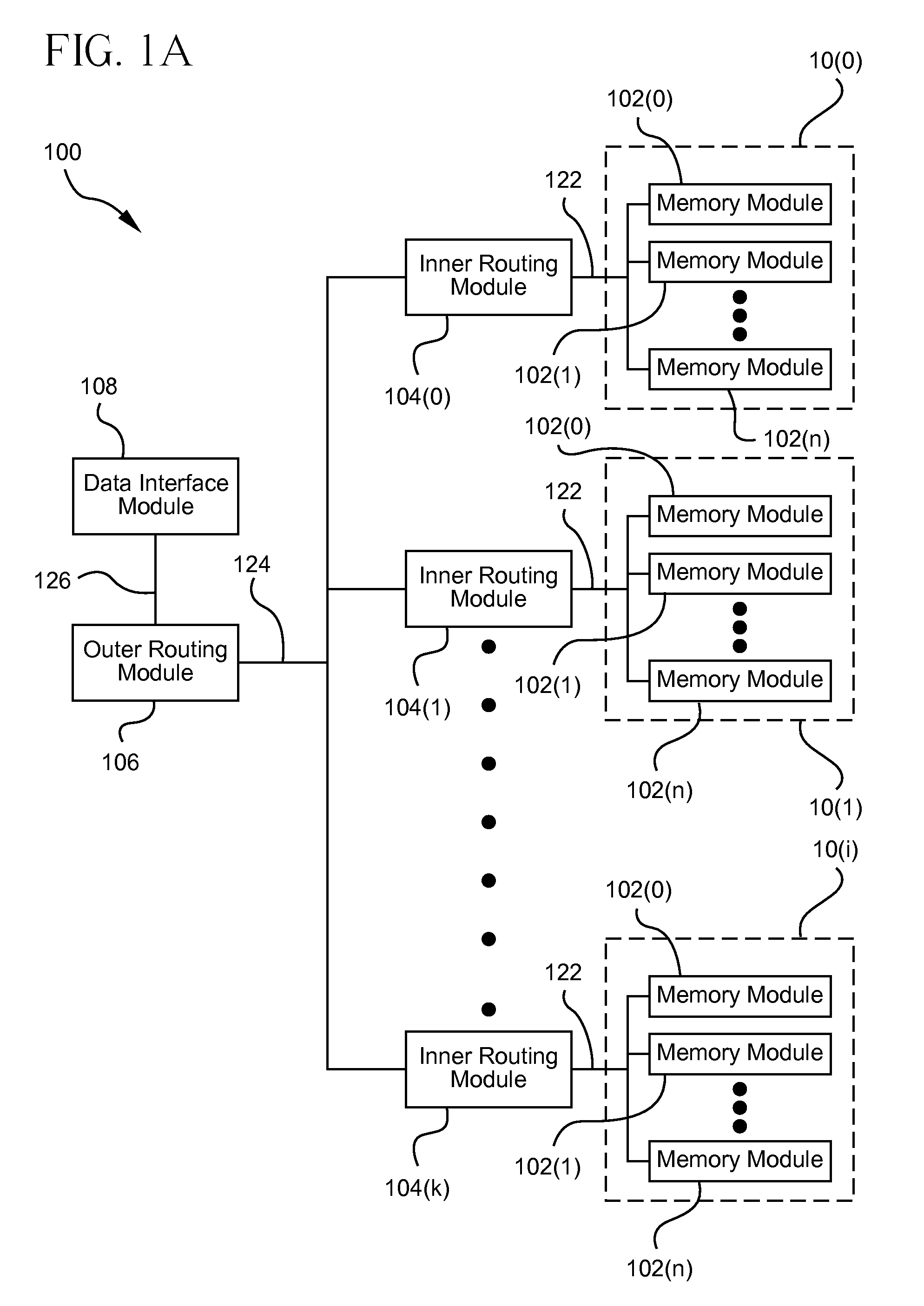

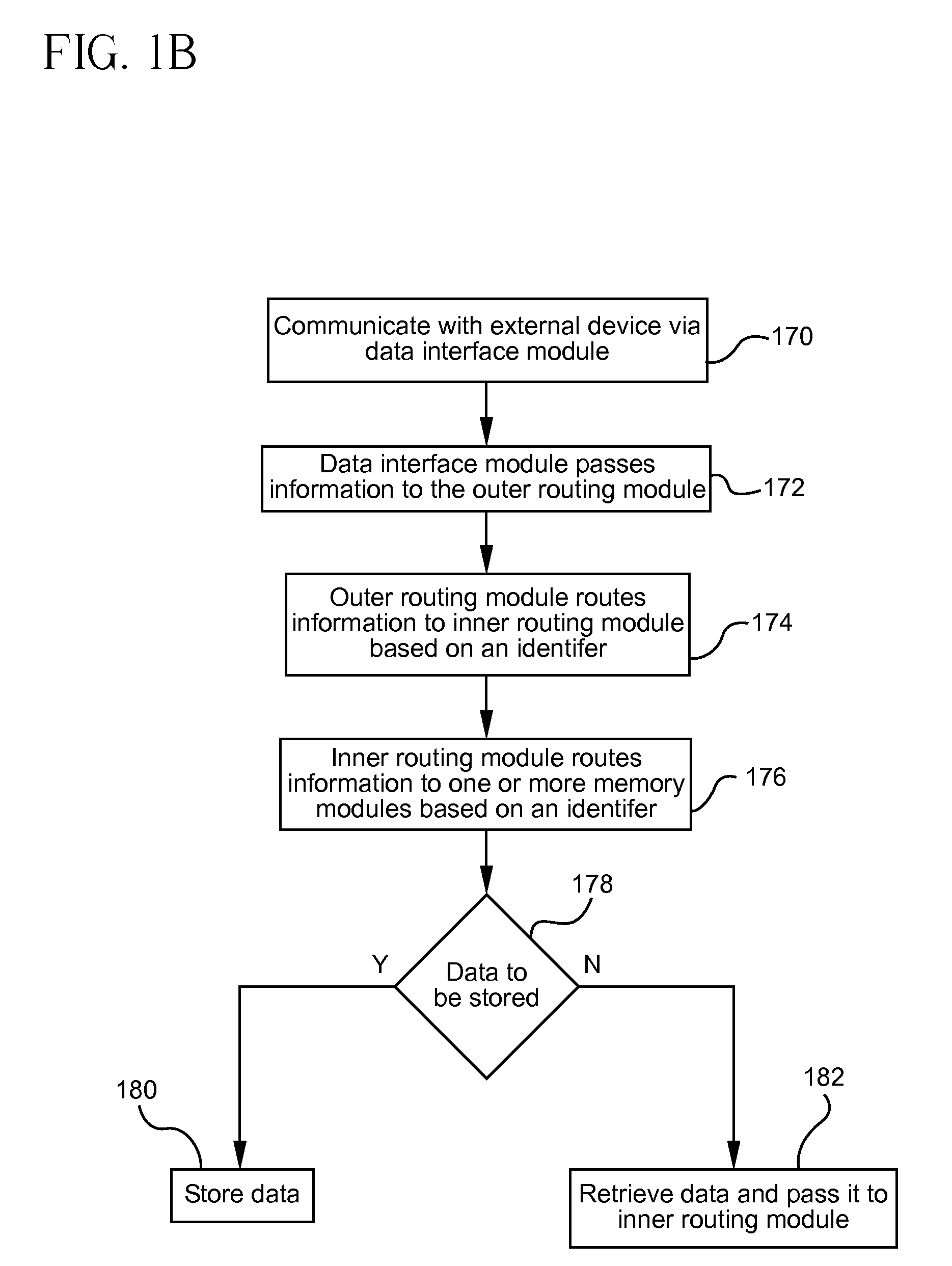

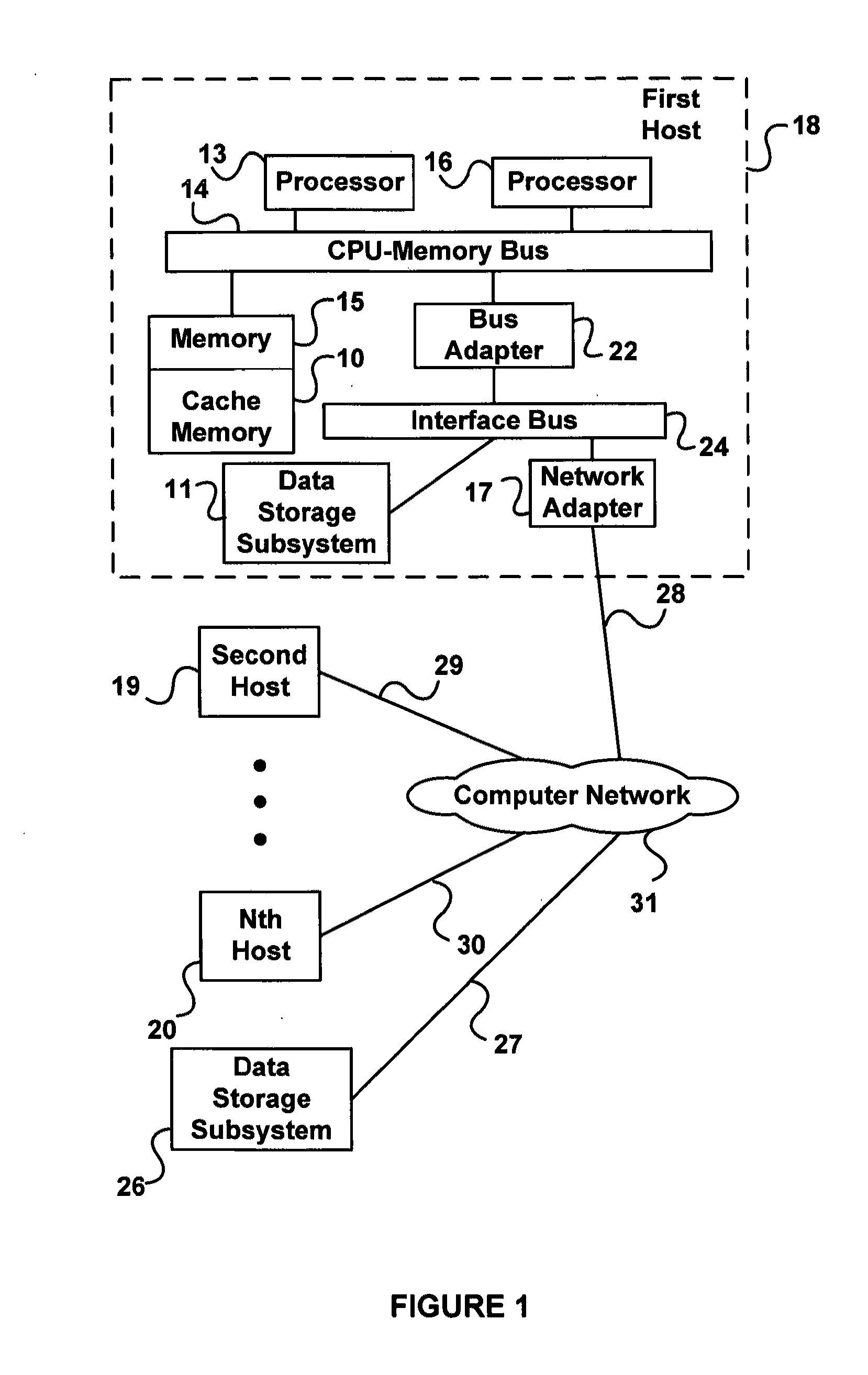

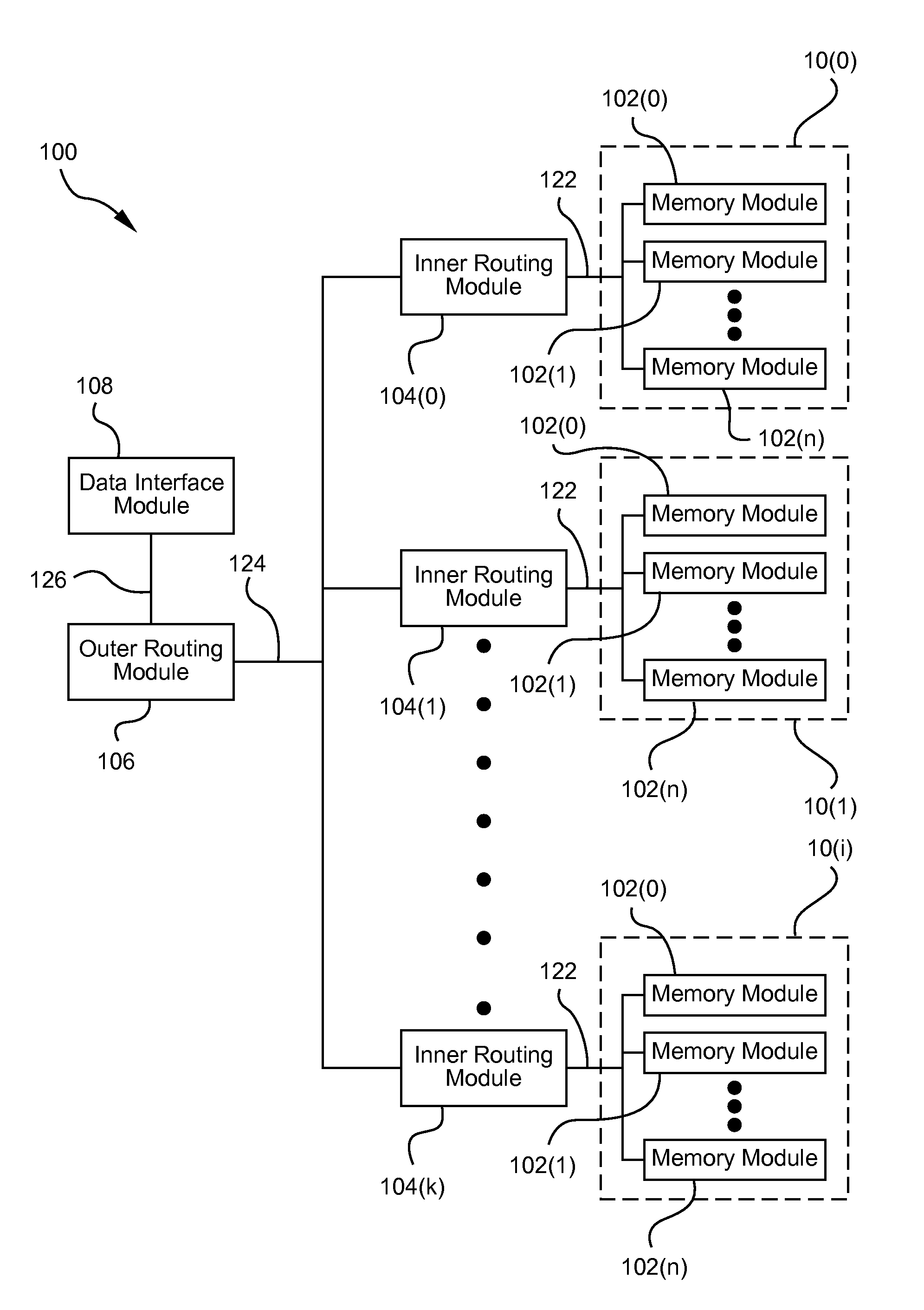

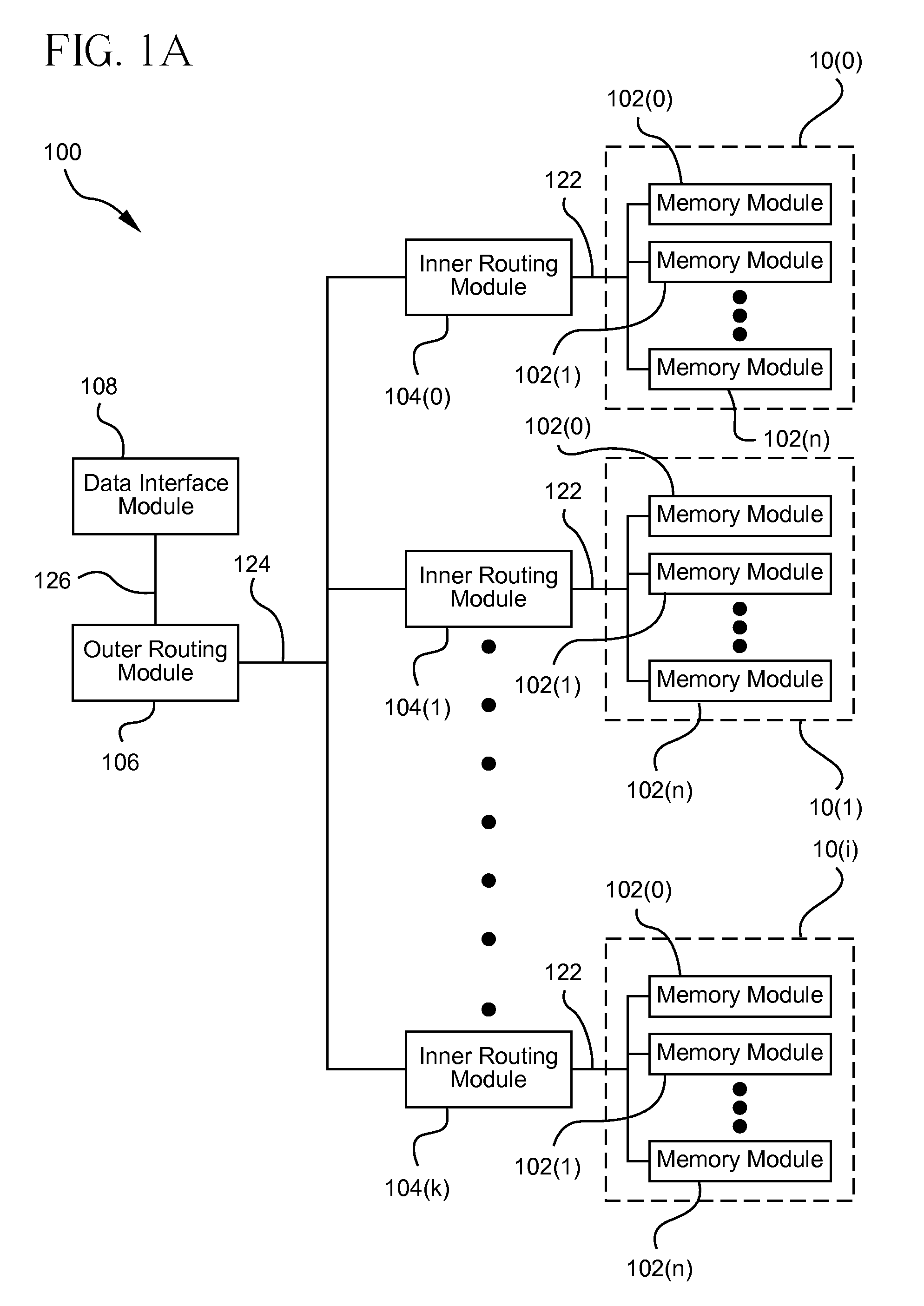

Scalable mass data storage device

ActiveUS20090094406A1Improve data transfer rateHigh bulk densityEnergy efficient ICTMemory adressing/allocation/relocationData centerVolumetric density

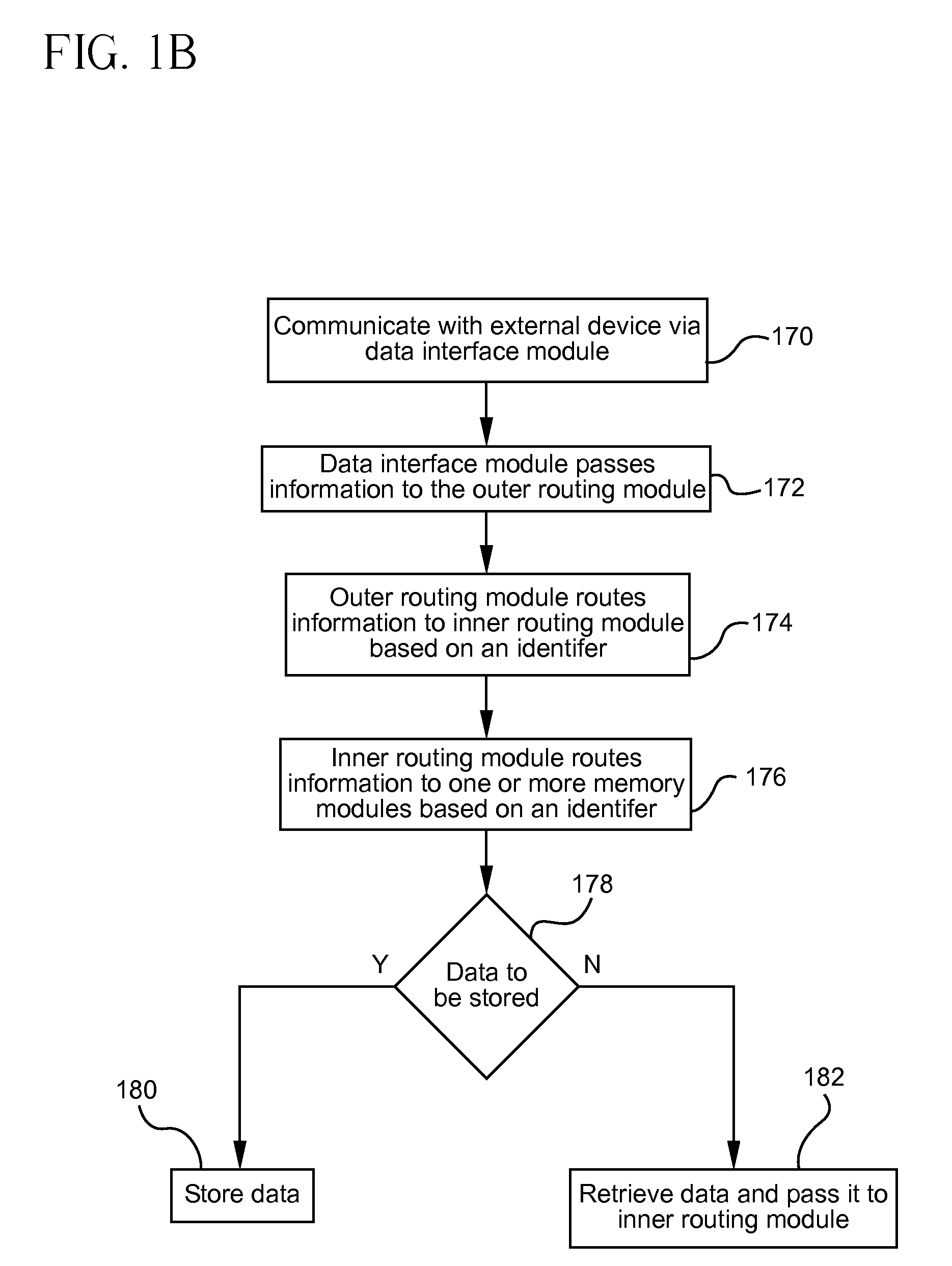

A scalable data storage device which includes non-volatile memory uses a networked bus system which can be employed on a single memory storage chip level or in a multi-chip package (MCP). The scalable data storage device uses data routing modules which are adapted to store incoming data and send outgoing data thereby providing decoupling of the networked buses. This arrangement enables significantly higher data transfer rates, surpassing DRAM SSDs at a fraction of the size and cost, provides increased volumetric density (1 TB in less than 1 cubic inch), and permits concurrency of operations. The scalable data storage device can be engineered to have a rewrite capability of over 500 times that of Flash RAM and can scale down to 8 bits and up to exabytes, yottabytes and beyond. The scalable data storage device may be used in a wide range of applications from large data centers to small consumer electronic products.

Owner:STACKSPEED INC +1

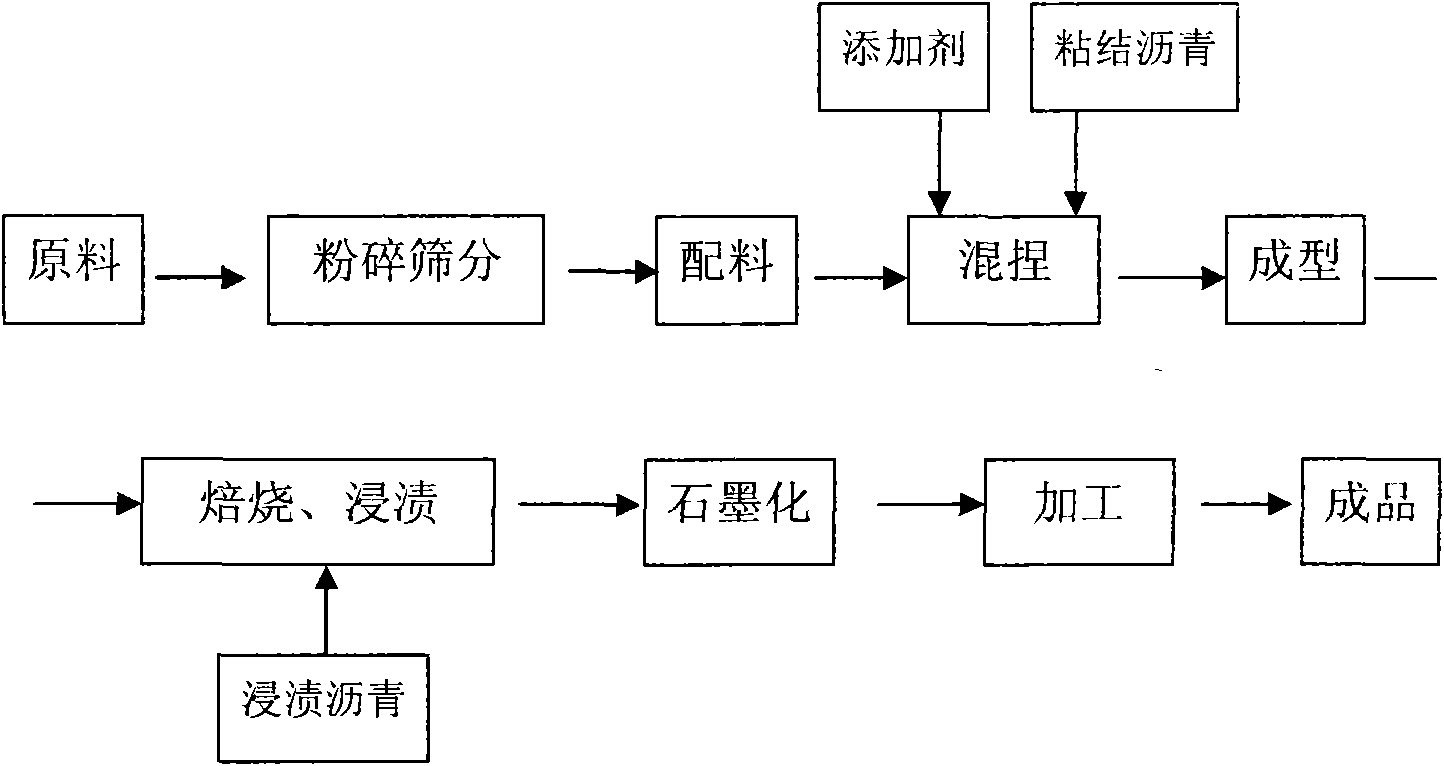

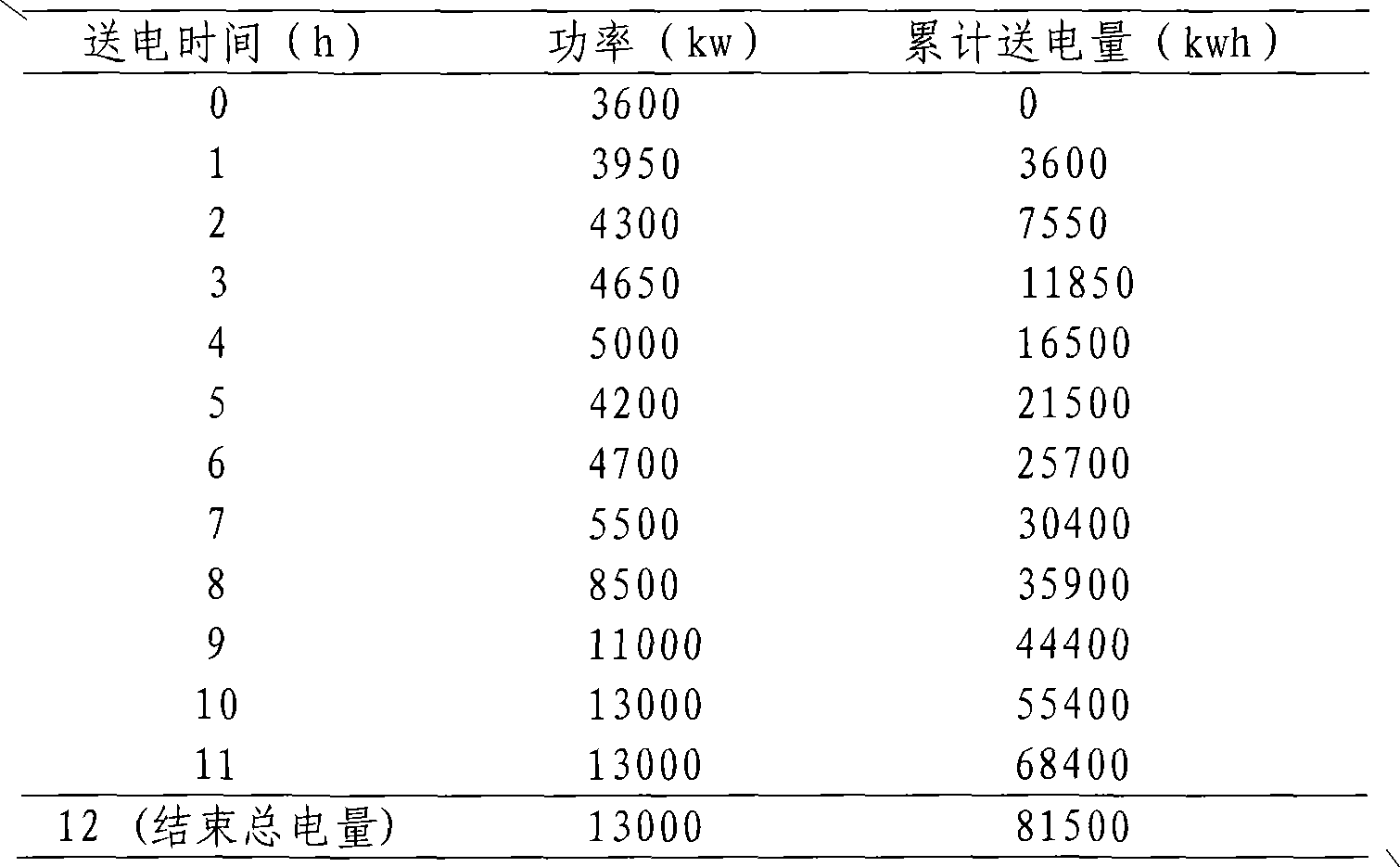

Ultra high power graphite resistor rod with 600mm diameter and method for producing the same

ActiveCN101553060ASolve capacitySolve the scale-up problemElectric discharge heatingVolumetric Mass DensityCoal

The present invention provides an ultra high power graphite resistor rod with 600mm diameter and a method for producing the same. The method utilizes domestic coal series acicular coke with low true density in main physicochemical standard, high heat expansion coefficient and sulphur content for producing the large-size ultra high power graphite resistor rod with 600mm diameter. Volumetric density, bending strength, elastic modulus, electric resistivity and heat expansion coefficient of the product reaches the international standard after detecting which can solve difficult problem that the domestic coal series acicular coke can not produce the large-size ultra high power graphite resistor rod with 600mm diameter because of low true density in main physicochemical standard, high heat expansion coefficient and sulphur content, and can realize localization for raw material acicular coke of the large-size ultra high power graphite resistor rod, simultaneity, also can solve problem that the acicular coke depends on importation in a long time and has high cost for restricting expanding yield and scale of the ultra high power graphite resistor rod in carbon industry. The product can reduce cost and improve economic performance.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

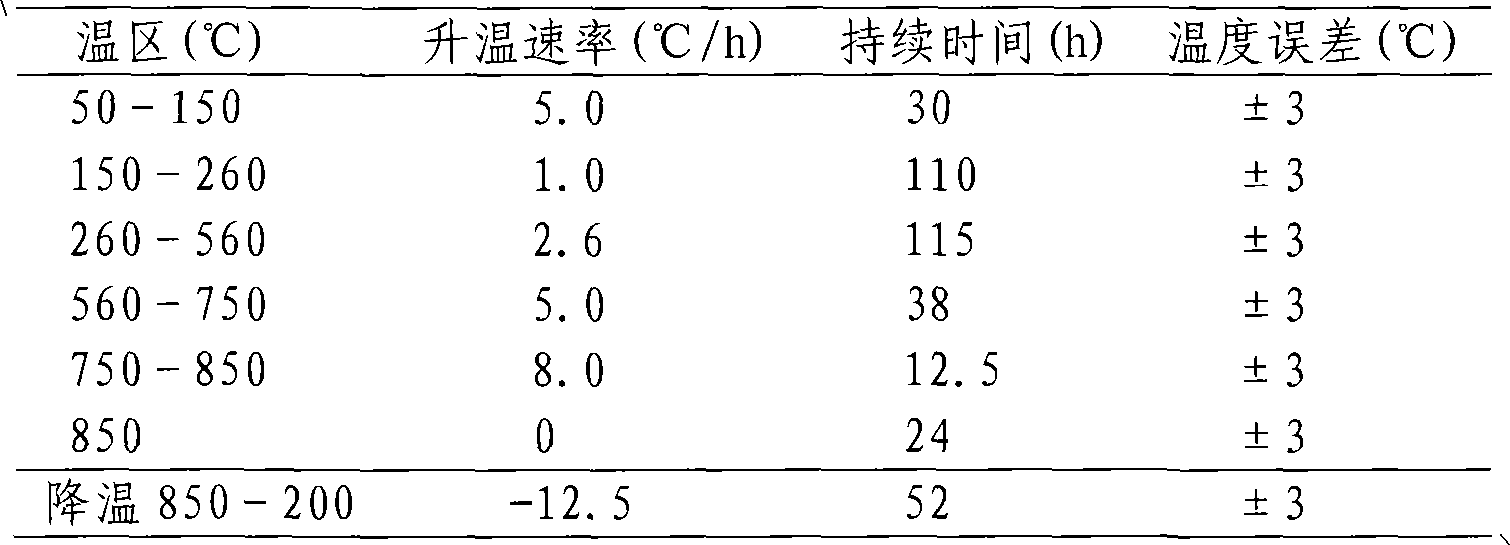

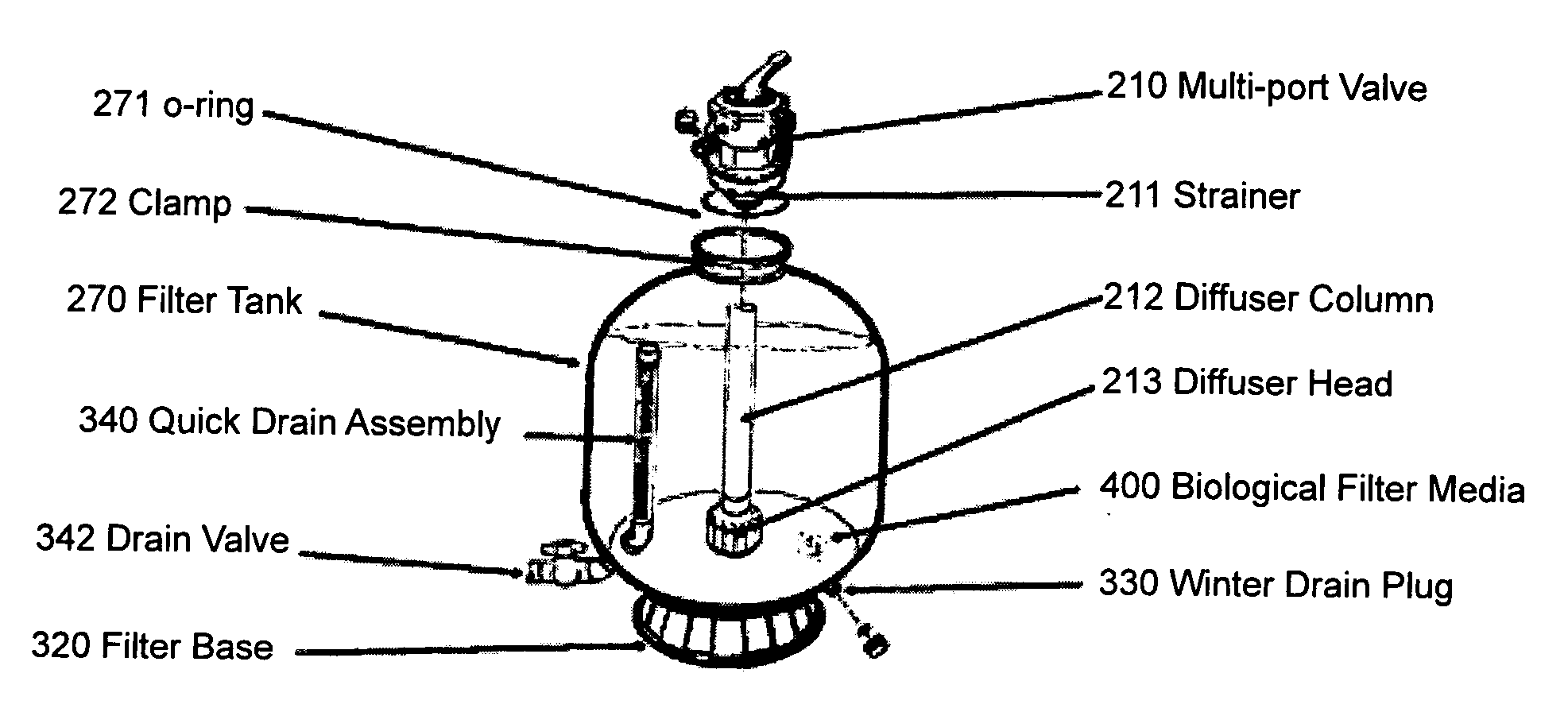

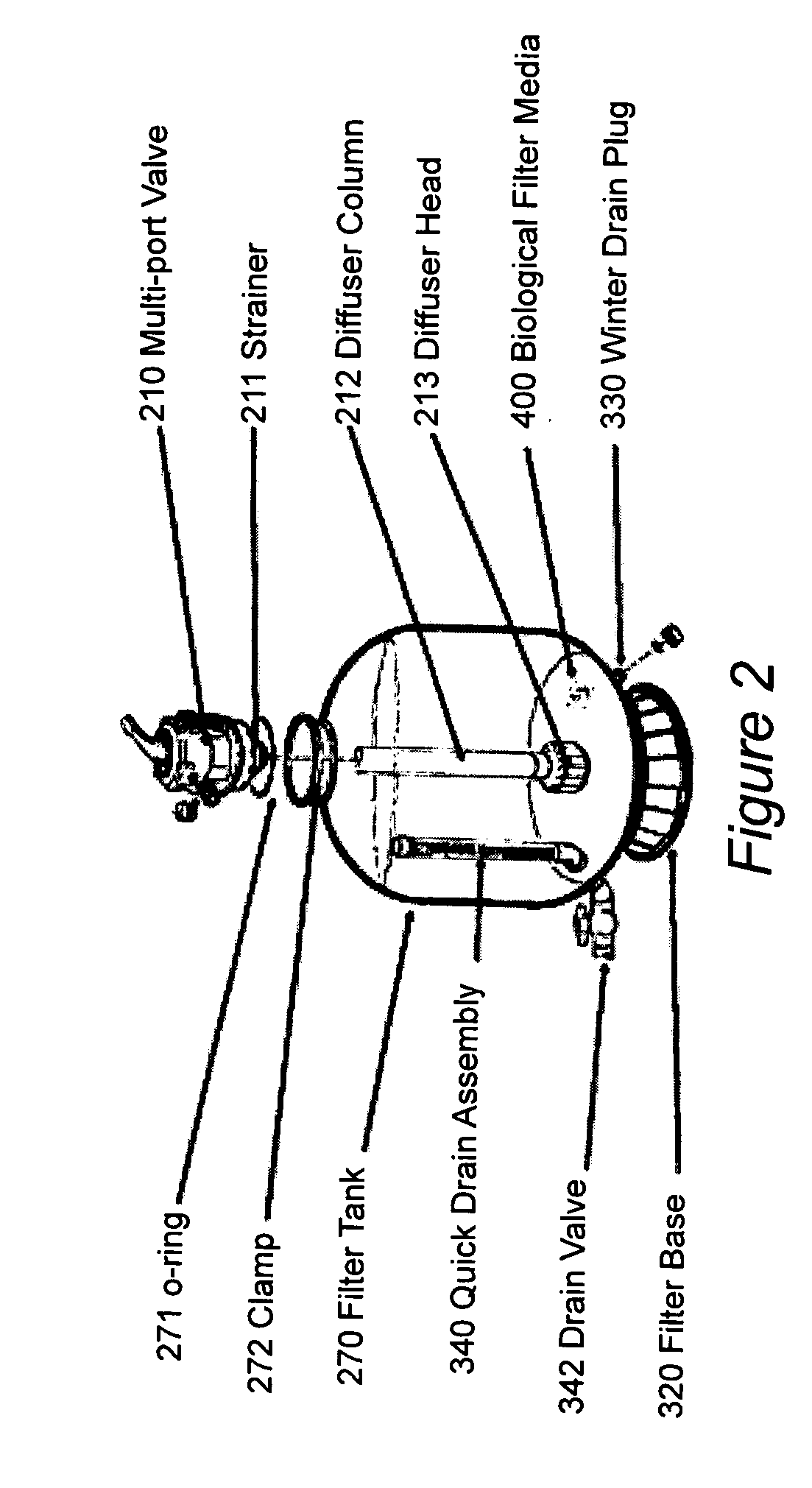

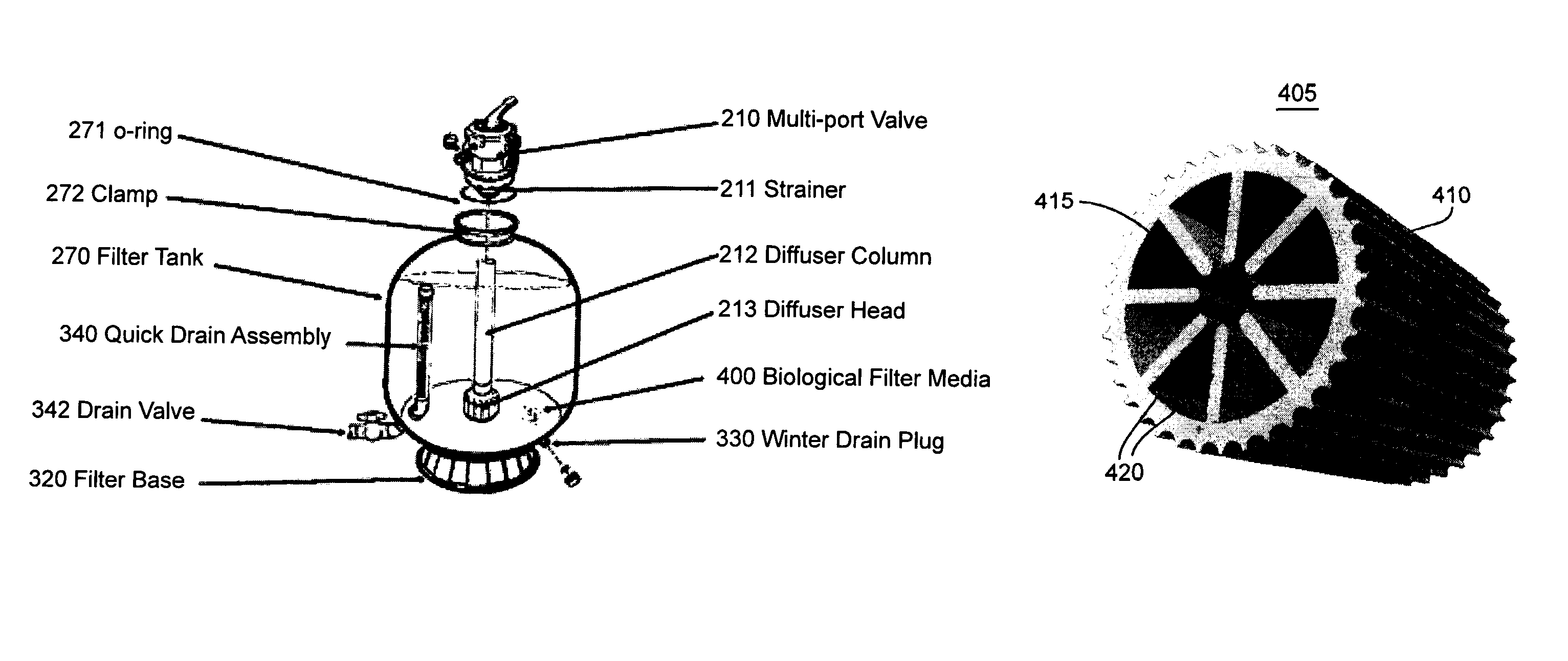

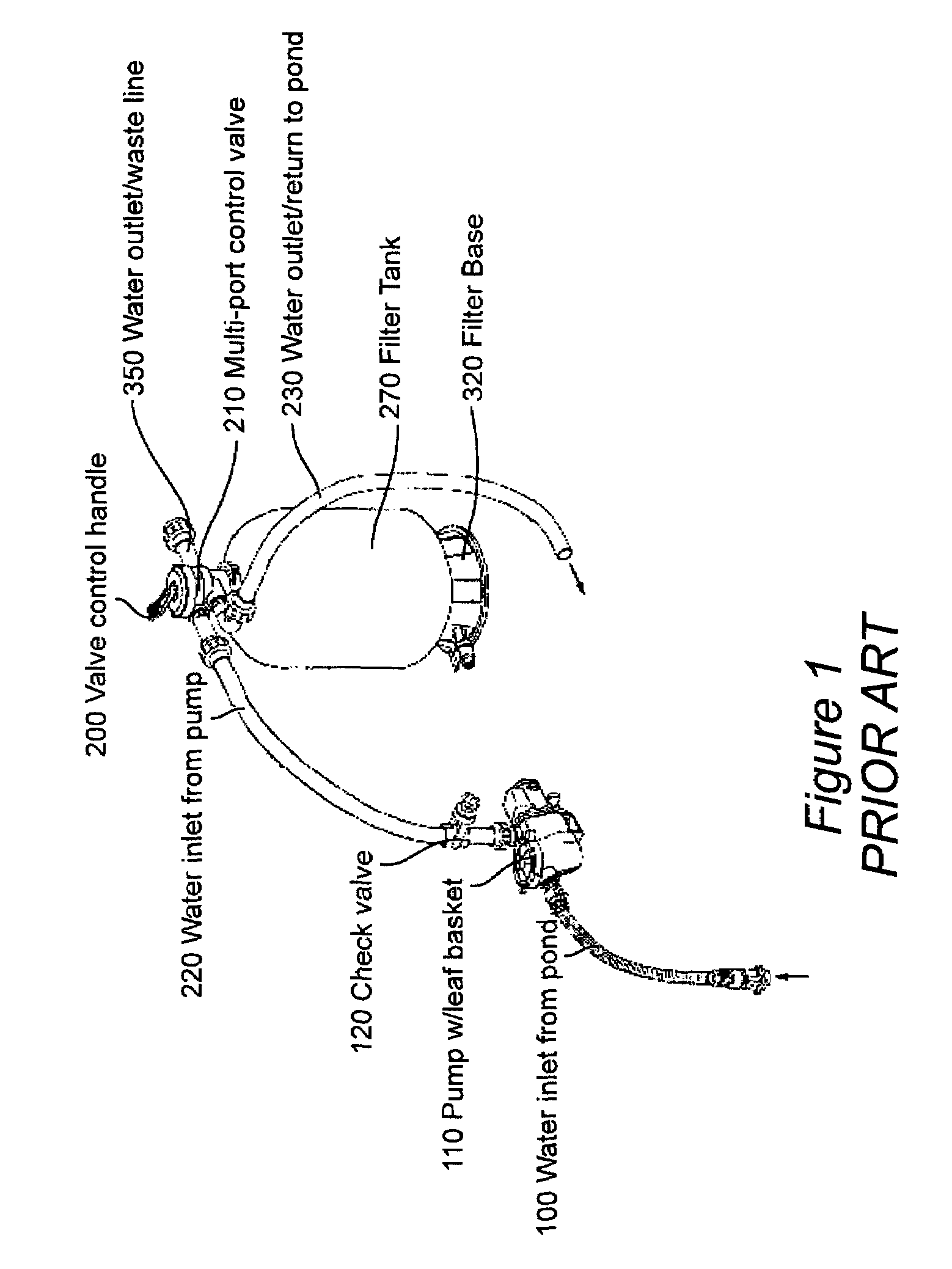

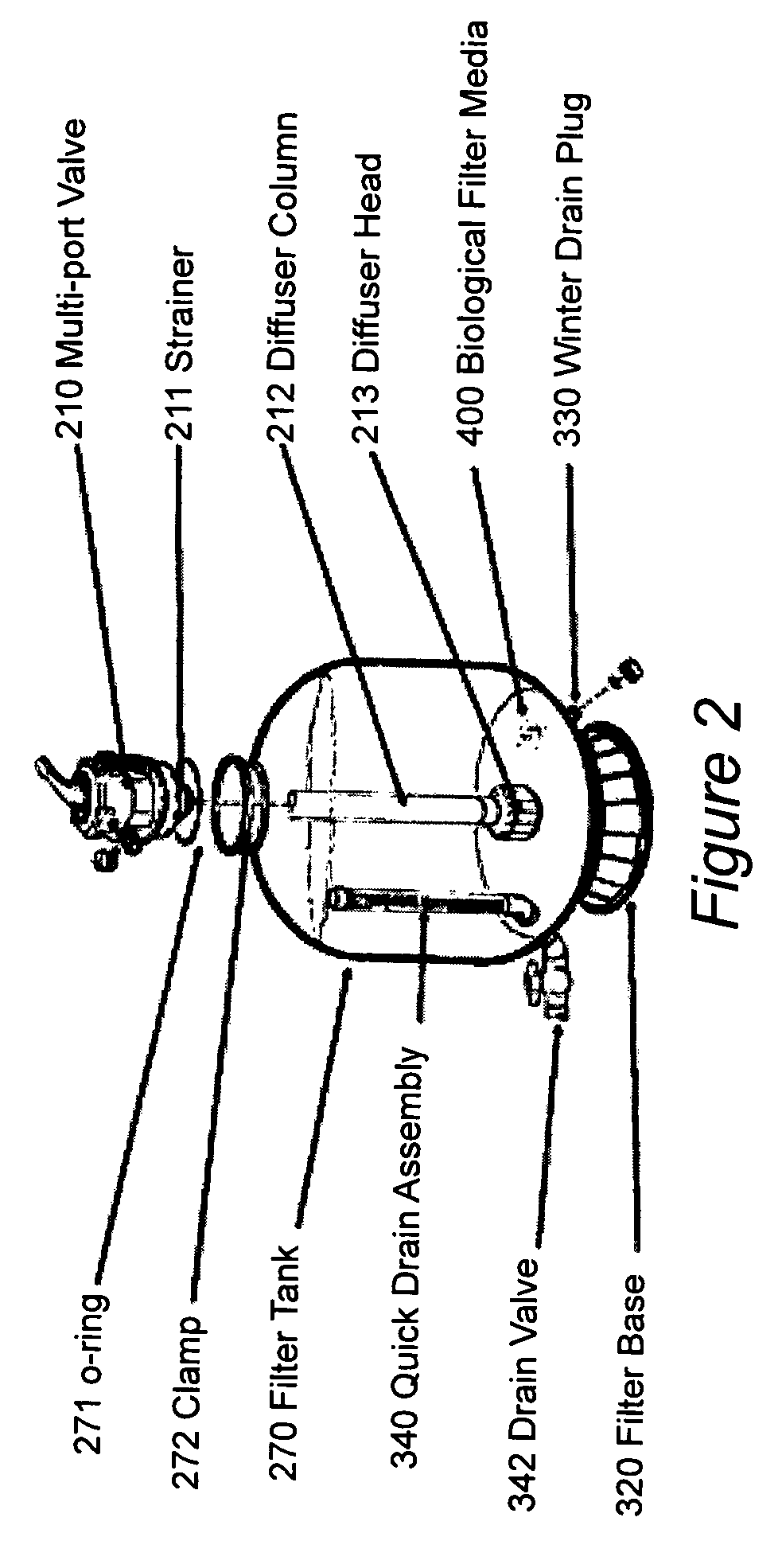

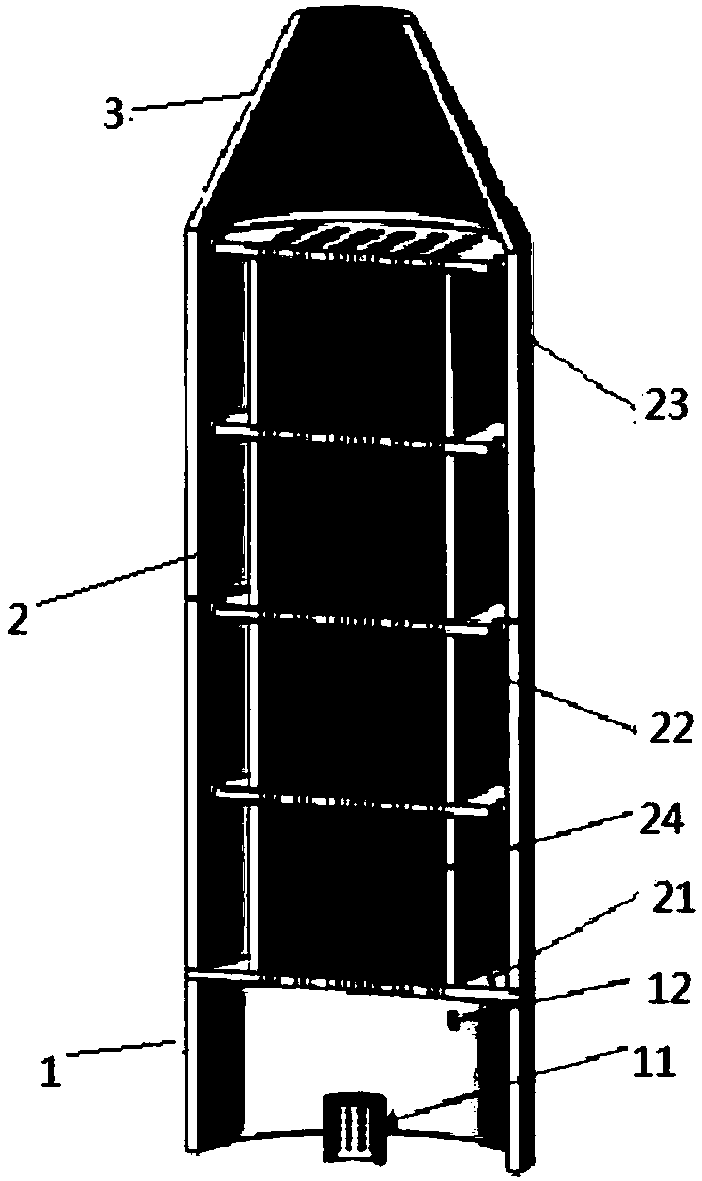

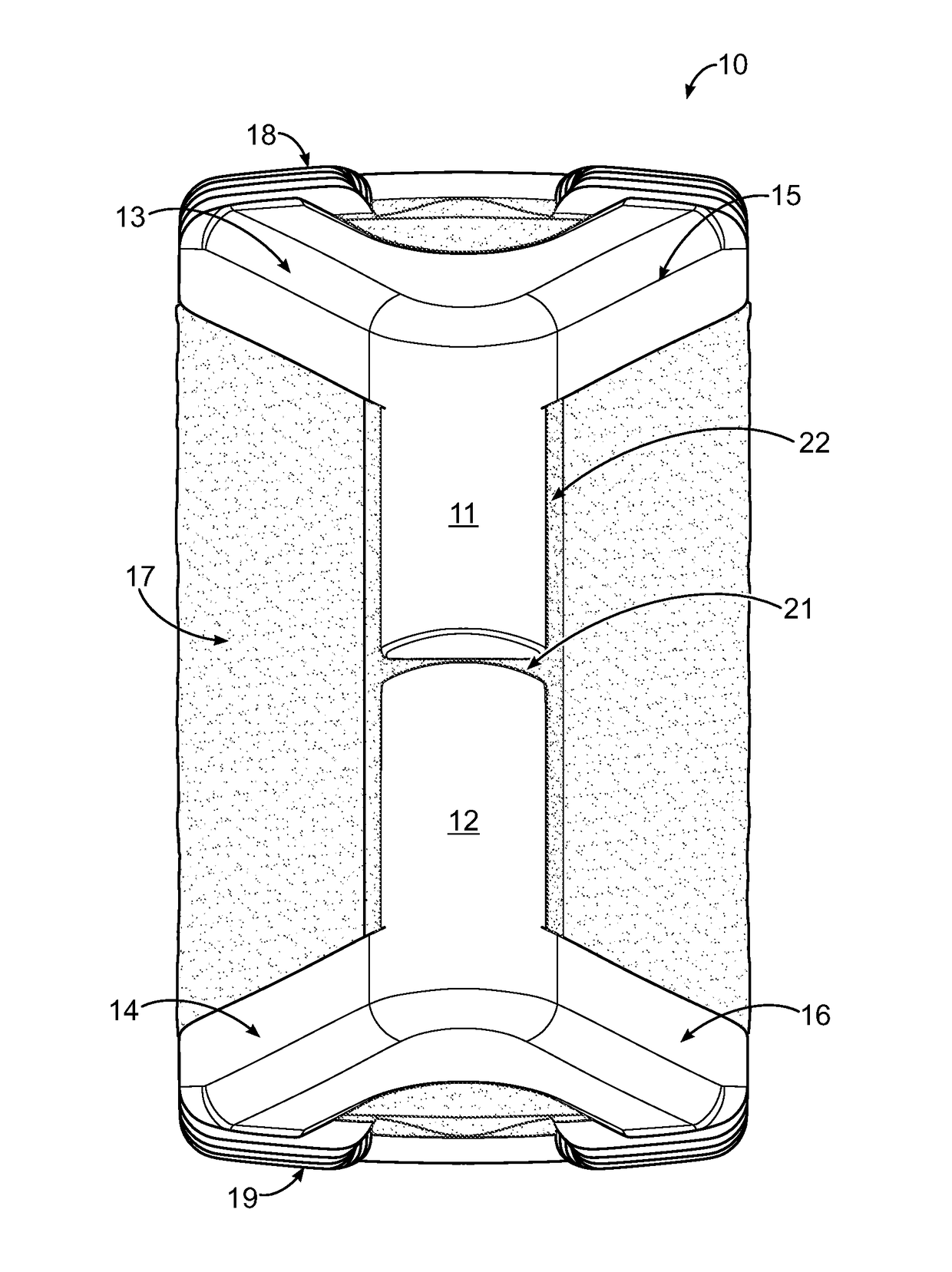

See-thru self cleaning biological filter system for aqua-culture

InactiveUS20060151366A1Mechanical and biological filtrationLong maintenance periodPisciculture and aquariaLoose filtering material filtersVertical tubeBiological filter

A system is described for collecting, filtering and removing dirt, debris, detritus, active organic materials, chemicals and toxins from water in fish ponds and general aqua-culture applications. This system includes a filter tank with supporting base containing biological filtration media, a multi-port valve, a strainer, a diffuser head, and a quick drain assembly. The filter tank is fabricated using transparent material allowing for visual inspection of the mechanical and biological activities inside the filter tank. The strainer and diffuser head are slotted so as to capture debris, retain filter media, and maintain unrestricted water flow. The quick drain is a vertical tube covered by drainage slots. The top end of the tube is capped. The bottom end of the tube extends through the filter tank wall to the exterior where a drain valve is attached. The biological filtration media are hollow plastic cylindrical structures with ridges on the external walls and free-standing fins on the internal walls that provide a high surface area-to-volume ratio and thus can support a high volumetric density of naturally occurring heterotrophic bacteria.

Owner:HOANG HUNG

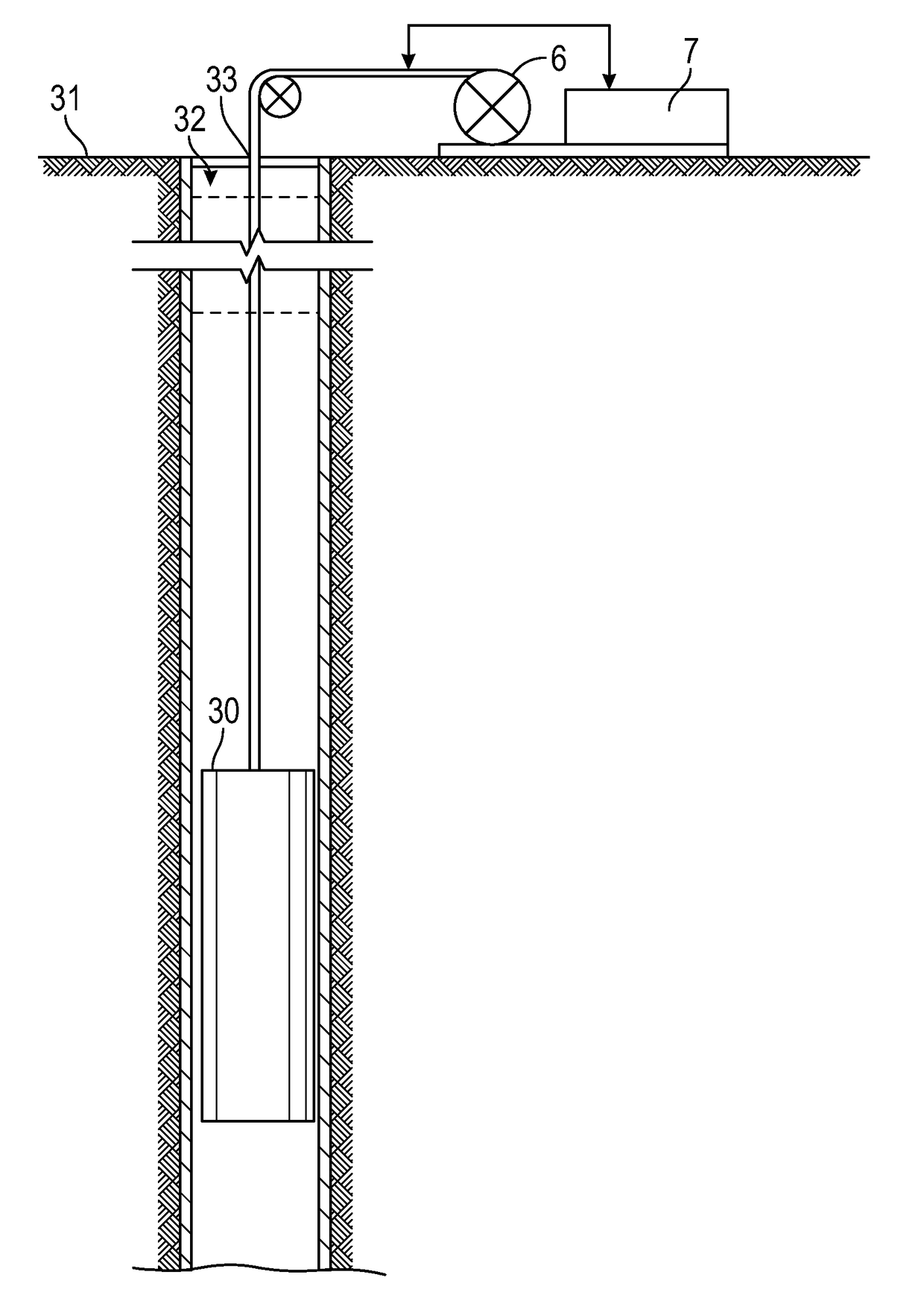

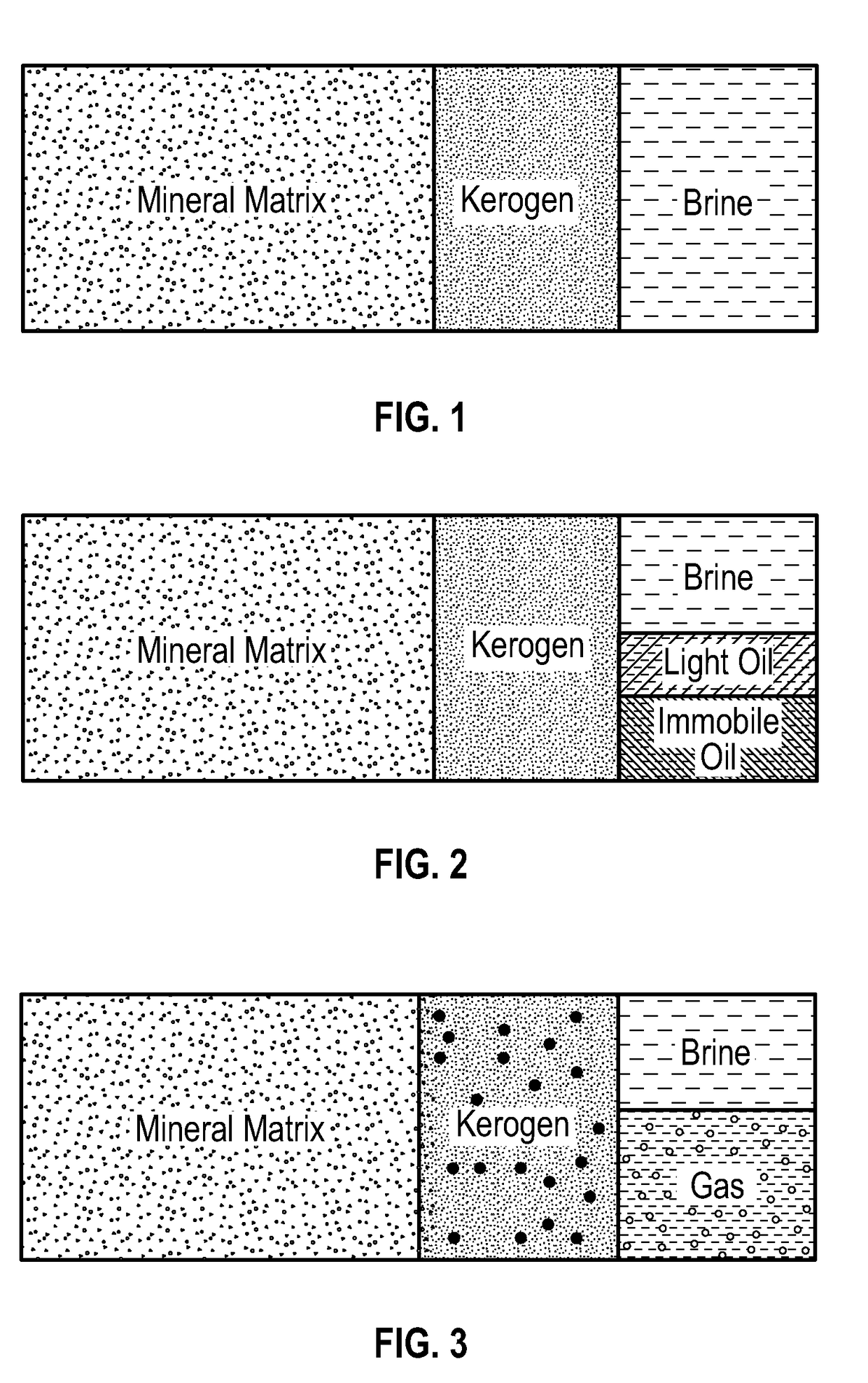

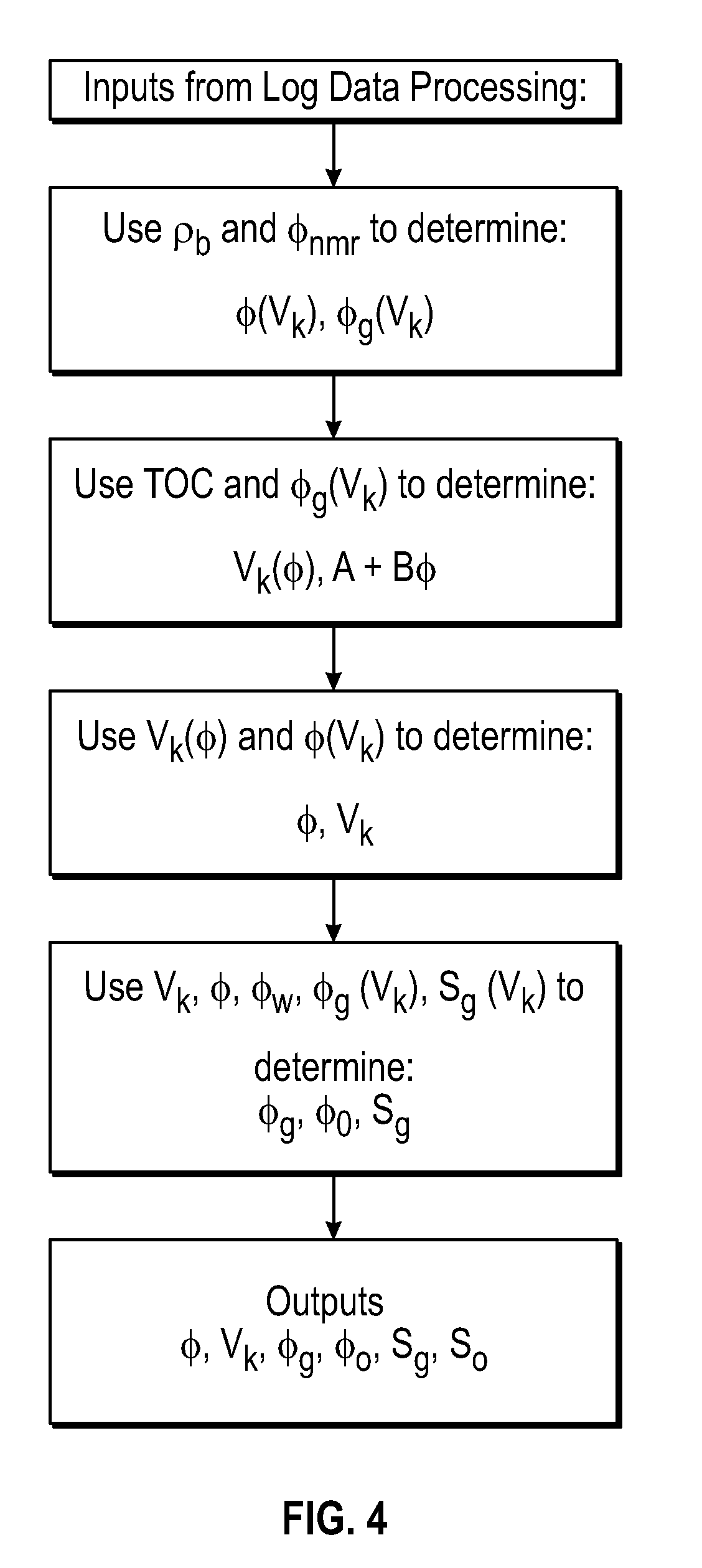

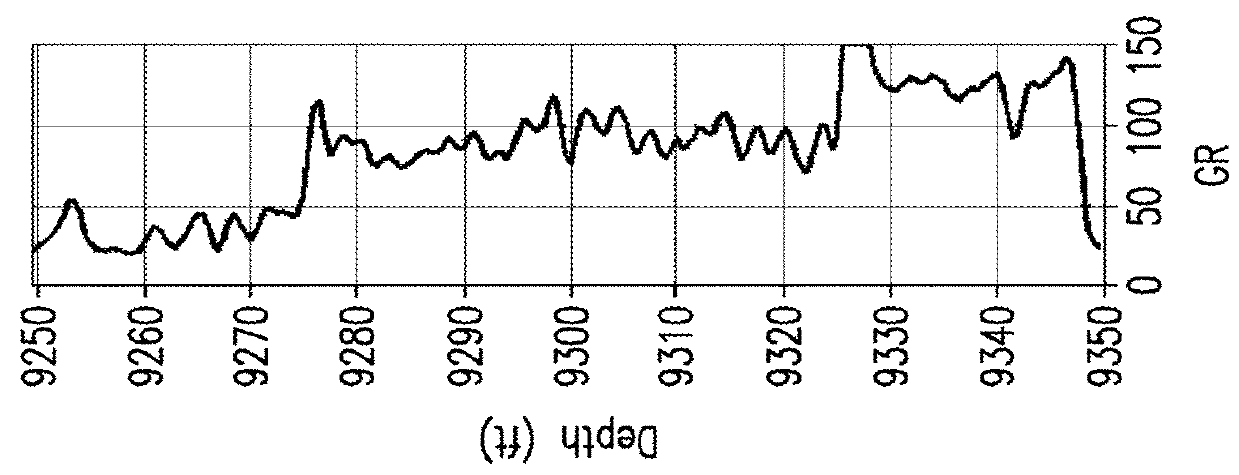

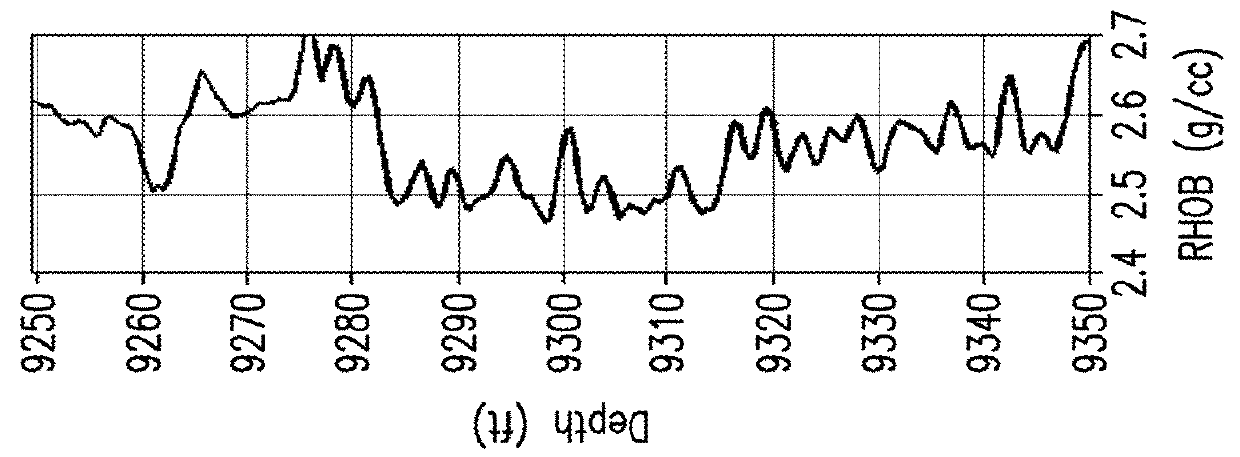

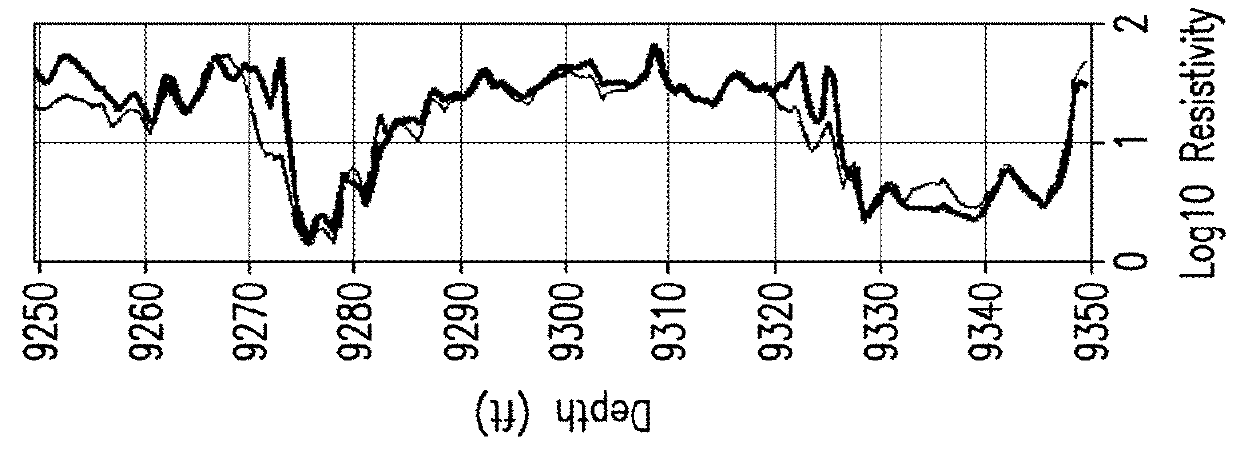

Method for formation evaluation of organic shale reservoirs using well logging data

ActiveUS20180321416A1Electric/magnetic detection for well-loggingMagnetic measurementsKerogenPorosity

Disclosed herein is a formation evaluation method including estimating a total porosity of an earth formation as a function of bulk density and total nuclear magnetic resonance (NMR) porosity of the earth formation. The total porosity of the earth formation as estimated underrepresents bitumen content. A gas filled porosity of the earth formation is estimated as a function of the bulk density and the total NMR porosity. A kerogen volume of the earth formation is estimated as a function of the gas filled porosity and a total organic carbon content of the earth formation. A bitumen filled total porosity is determined as a function of the estimated kerogen volume and the estimated total porosity of the earth formation. A corrected kerogen volume of the earth formation is determined as a function of the estimated kerogen volume and the estimated total porosity of the earth formation.

Owner:SCHLUMBERGER TECH CORP

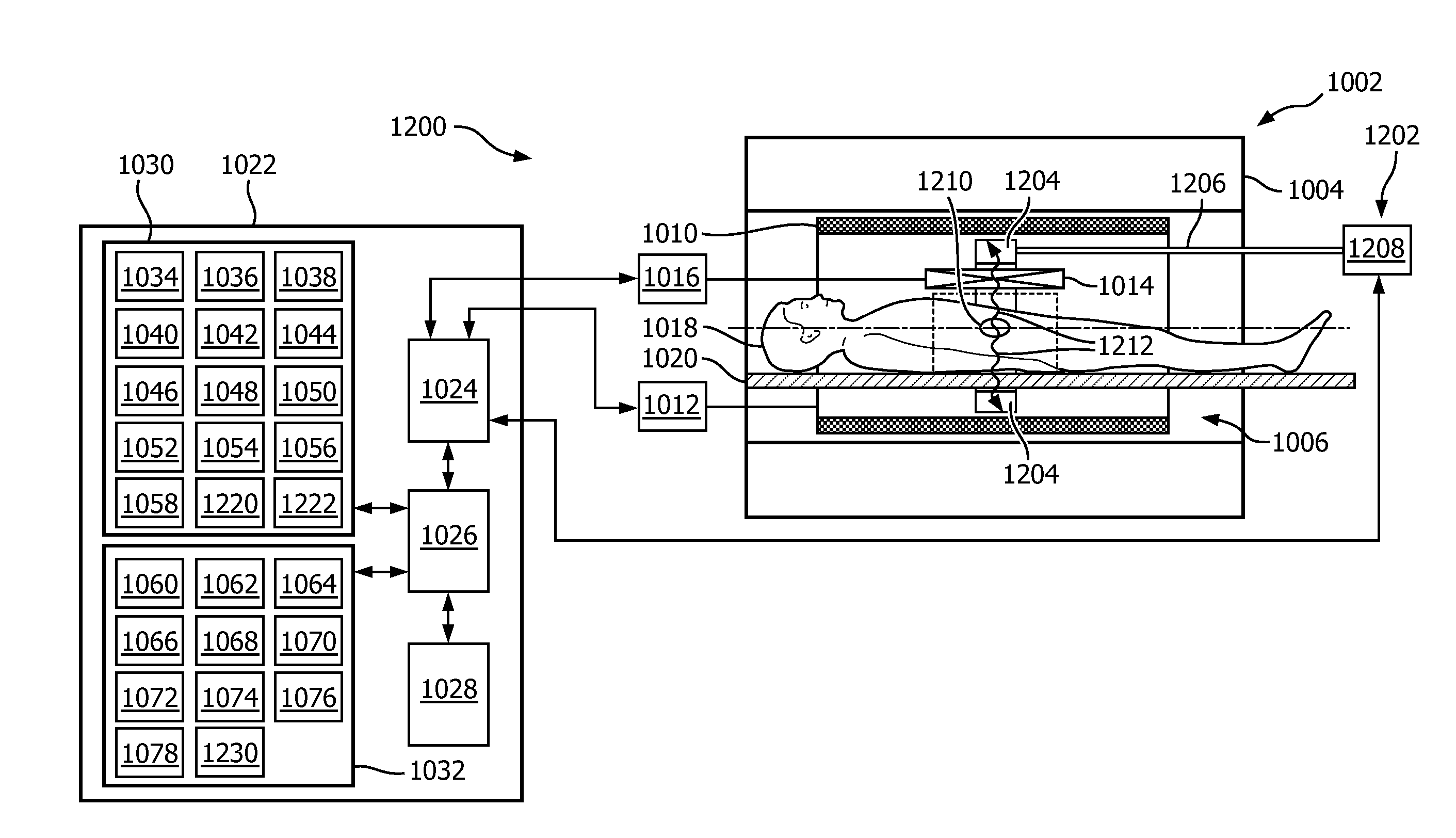

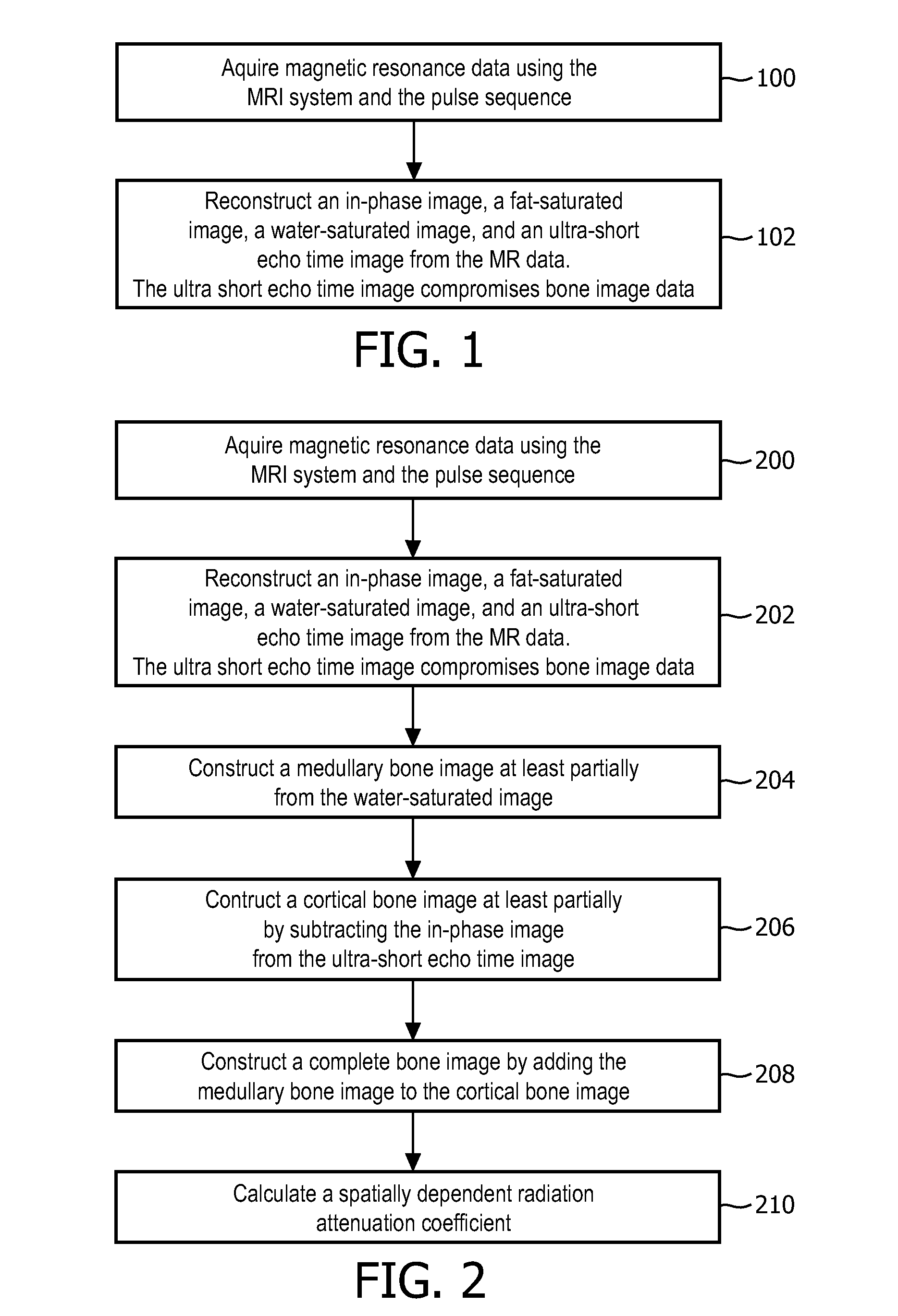

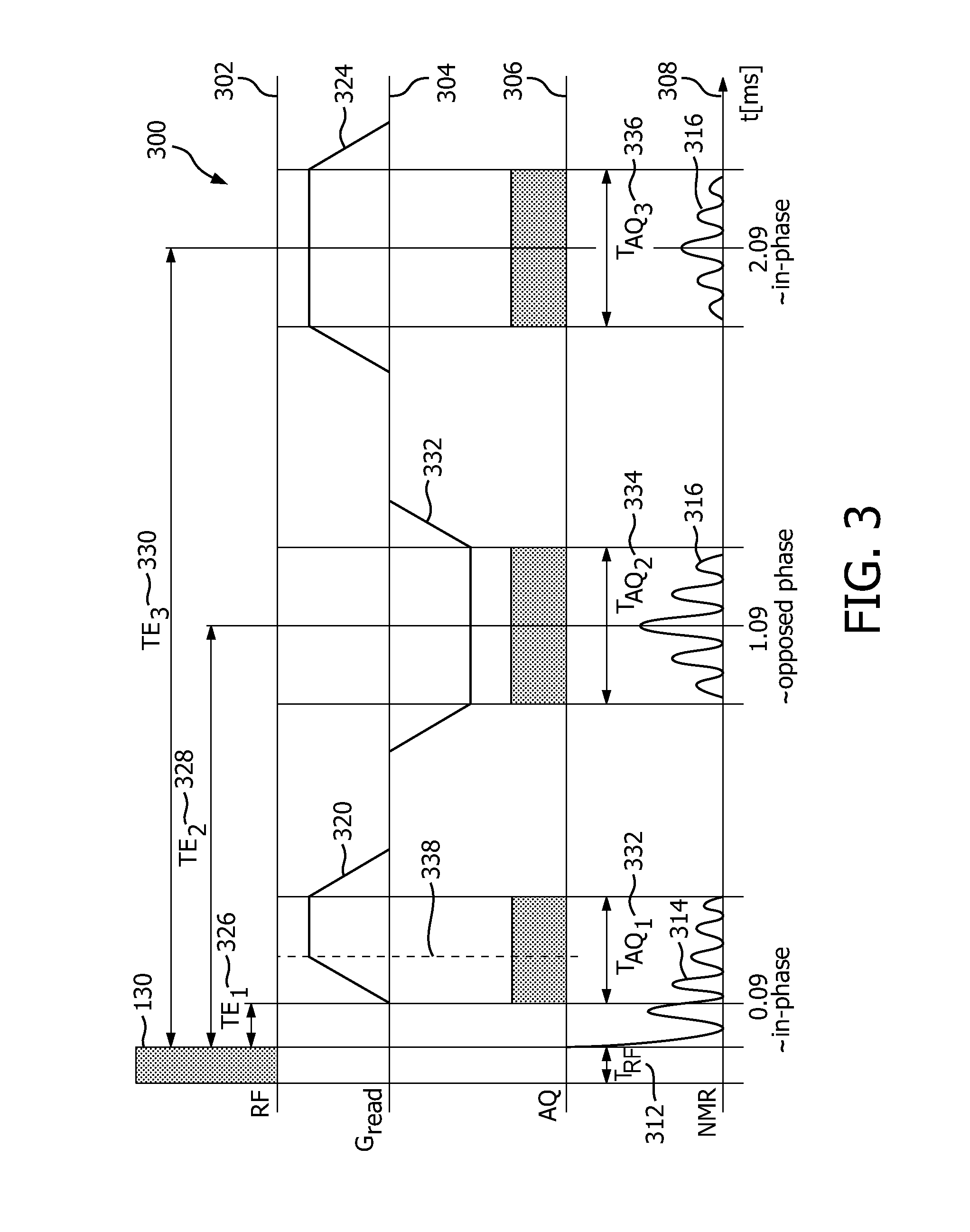

Method and system using magnetic resonance imaging for tissue classification and bulk-density assignment

InactiveUS20140296696A1Reliable identificationEasy to separateUltrasonic/sonic/infrasonic diagnosticsPatient positioning for diagnosticsResonanceVolumetric density

An apparatus includes a magnetic resonance imaging system, a processor for controlling the apparatus, and a memory containing machine executable instructions and a pulse sequence. The machine executable instructions and pulse sequence cause the processor to control the apparatus to: acquire magnetic resonance data from an imaging volume, wherein the magnetic resonance data includes gradient echo data; segment the magnetic resonance data into a plurality of segments, the segments including a fat segment, a water segment, a cortical bone segment, and an air segment; and create a bulk density map of the imaging volume from the segments.

Owner:KONINKLJIJKE PHILIPS NV

See-thru self cleaning biological filter system for aqua-culture

InactiveUS7468134B2Eliminate wasteFlow of waterWater cleaningTreatment using aerobic processesVertical tubeBiological filter

A system is described for collecting, filtering and removing dirt, debris, detritus, active organic materials, chemicals and toxins from water in fish ponds and general aqua-culture applications. This system includes a filter tank with supporting base containing biological filtration media, a multi-port valve, a strainer, a diffuser head, and a quick drain assembly. The filter tank is fabricated using transparent material allowing for visual inspection of the mechanical and biological activities inside the filter tank. The strainer and diffuser head are slotted so as to capture debris, retain filter media, and maintain unrestricted water flow. The quick drain is a vertical tube covered by drainage slots. The top end of the tube is capped. The bottom end of the tube extends through the filter tank wall to the exterior where a drain valve is attached. The biological filtration media are hollow plastic cylindrical structures with ridges on the external walls and free-standing fins on the internal walls that provide a high surface area-to-volume ratio and thus can support a high volumetric density of naturally occurring heterotrophic bacteria.

Owner:HOANG HUNG

Method for batch preparation of uniform density carbon/carbon composite flat by using limited domain reactor

The invention discloses a method for batch preparation of a uniform density carbon / carbon composite material flat by using a limited domain reactor. The limited domain reactor comprises a gas pretreatment device, a gas collection device and a deposition device; the deposition device comprises m gas separation plates, an outer cylinder and m-1 groups of side plates; the method comprises the steps that carbon fiber flat prefabricated bodies are erected in a deposition chamber composed of the m gas separation plates and the m-1 groups of side plates, the deposition chamber is further divided intoa plurality of narrow-area reaction space, it is ensured that the carbon fiber flat prefabricated bodies are erected in a blank area of the m gas separation plate, and a barrier to airflow is notformed so that the airflow can be evenly distributed. The method has the advantages of simple process, convenient operation, high utilization rate of carbon source gas and short process period, and the uniformity of bulk density of the obtained monomer carbon / carbon composite material flat is less than +-0.05 g / cm<3>.

Owner:CENT SOUTH UNIV

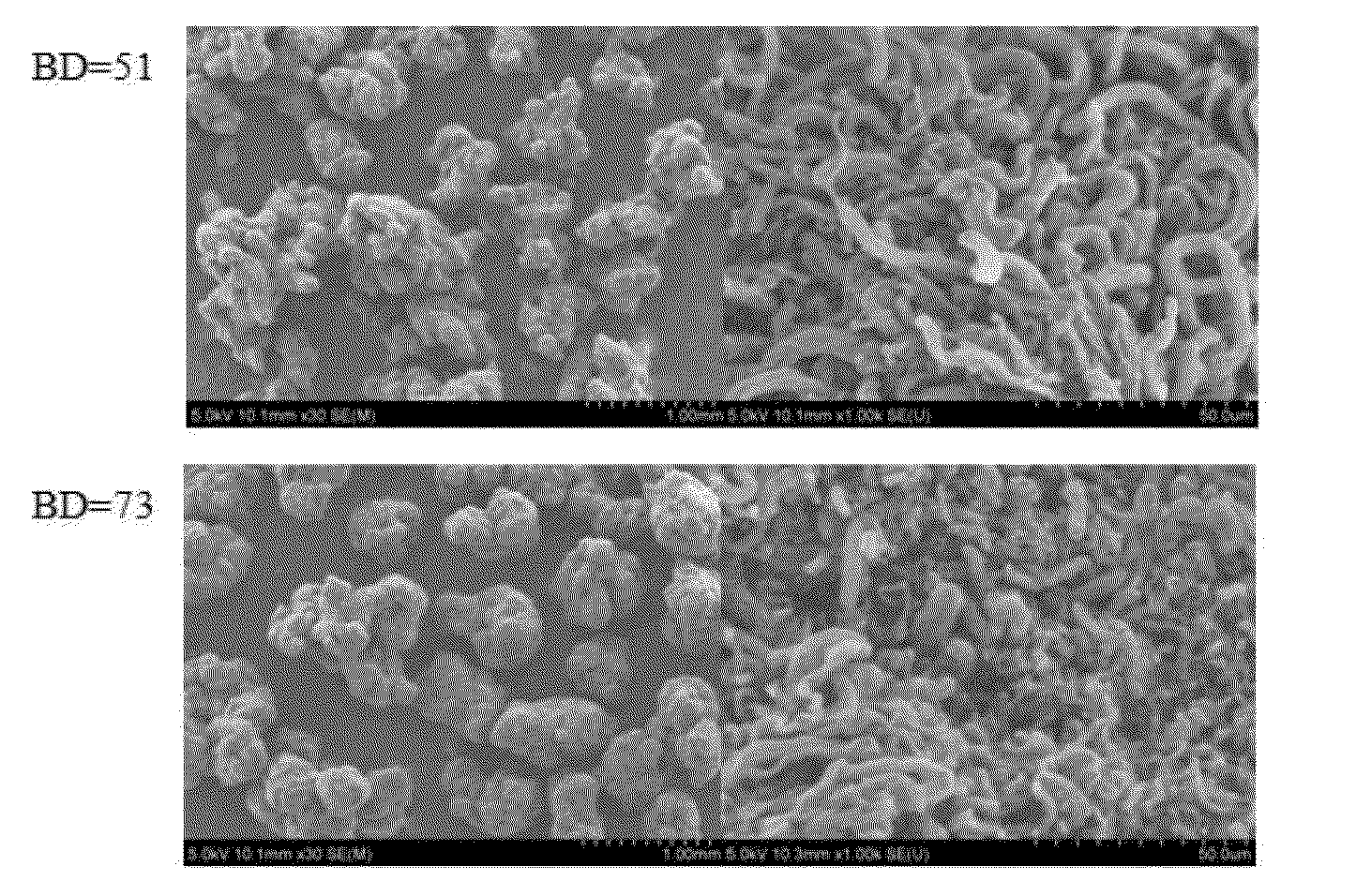

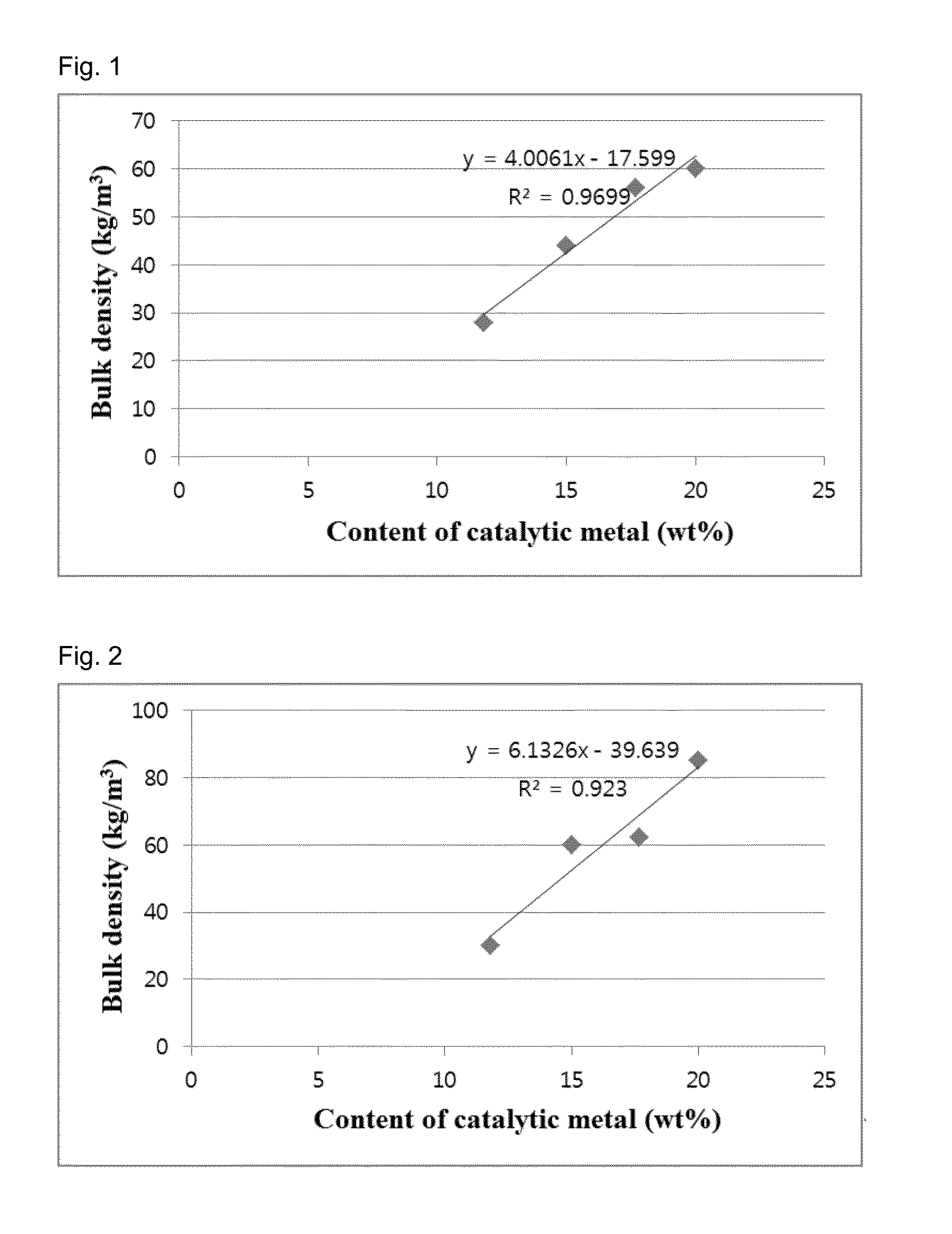

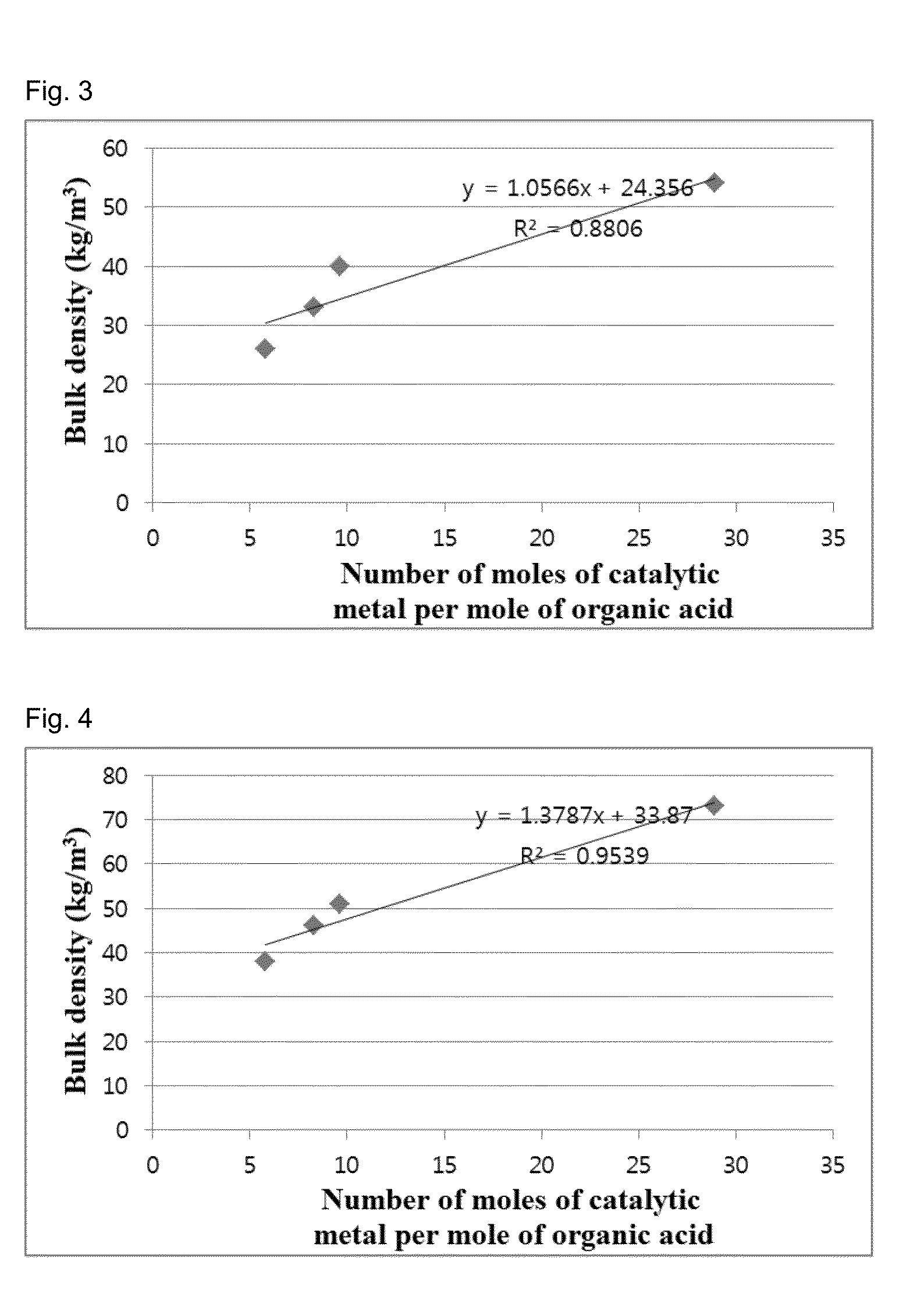

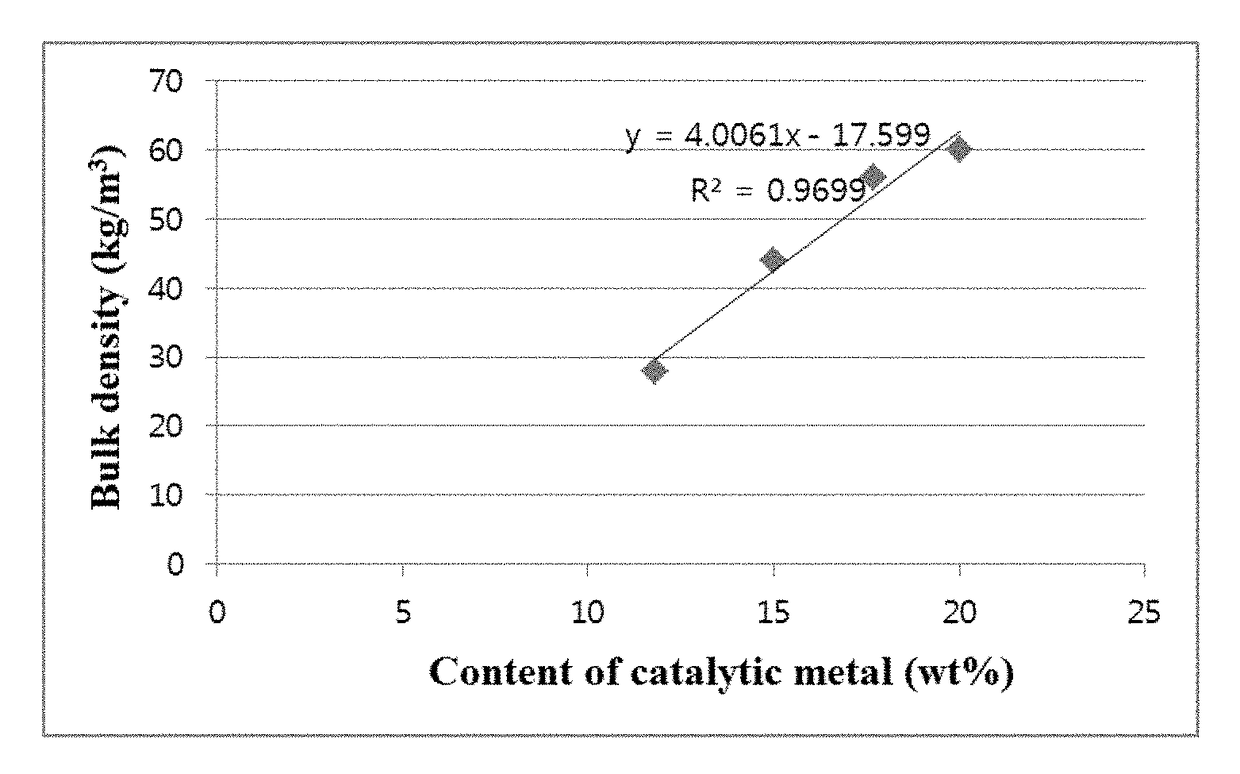

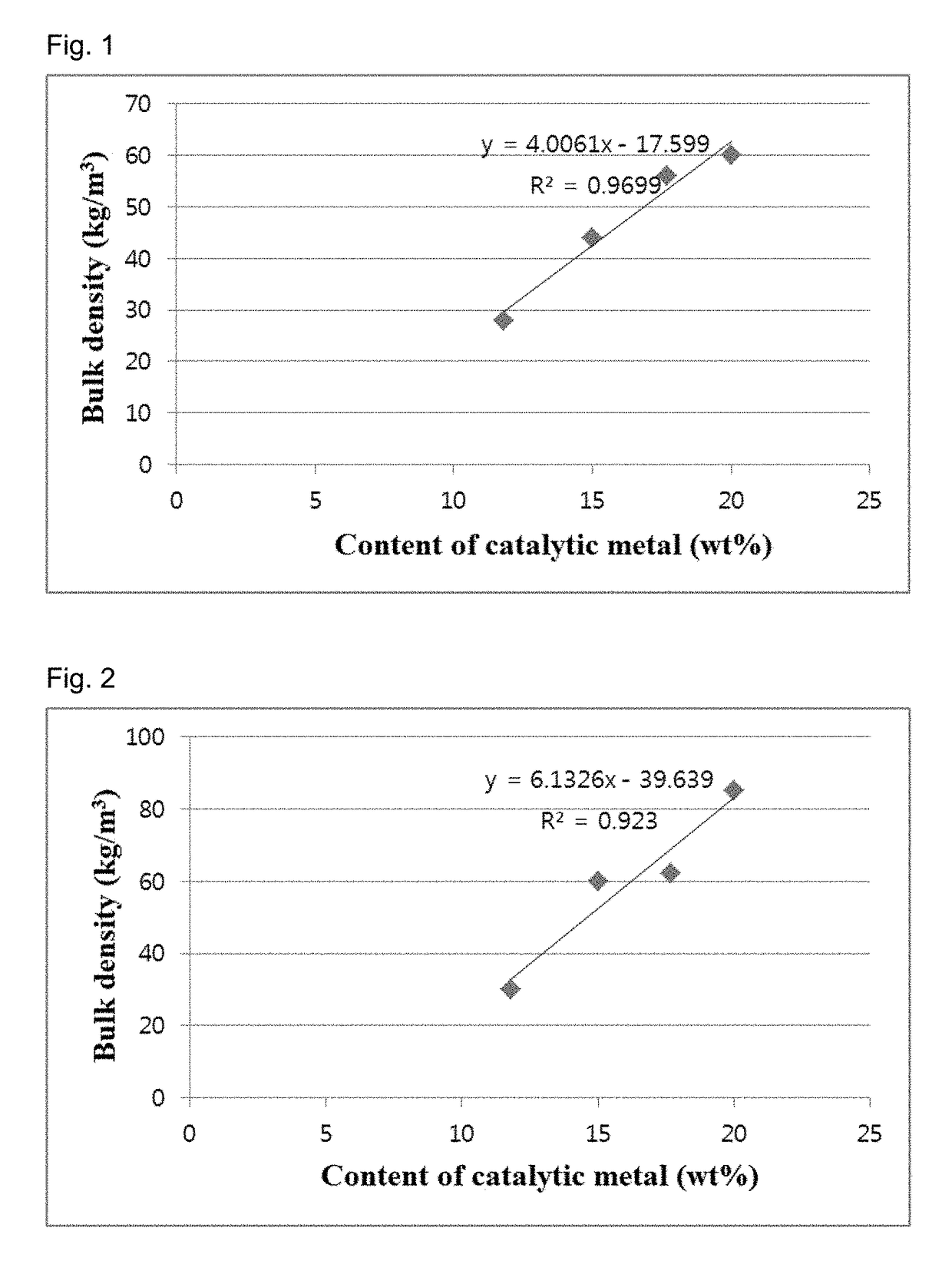

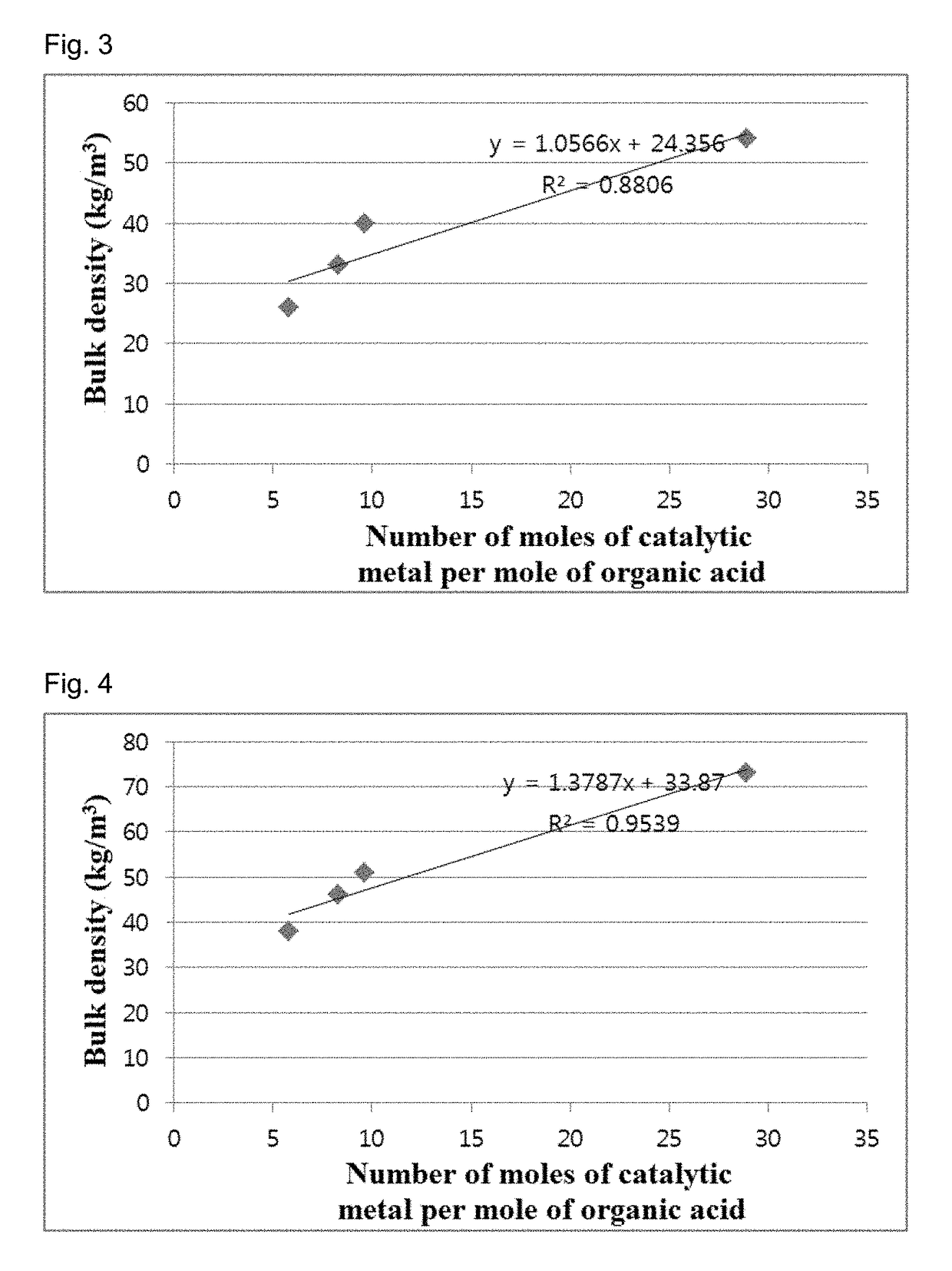

Method for controlling bulk density of carbon nanotube agglomerate

ActiveUS20150298974A1Readily dispersibleGood physical propertiesCarbon nanotubesCatalyst activation/preparationCarbon nanotubeVolumetric density

The present invention relates to a method for producing a carbon nanotube aggregate whose bulk density is easily controllable. Therefore, the present invention provides a carbon nanotube aggregate suitable for use in various fields.

Owner:LG CHEM LTD

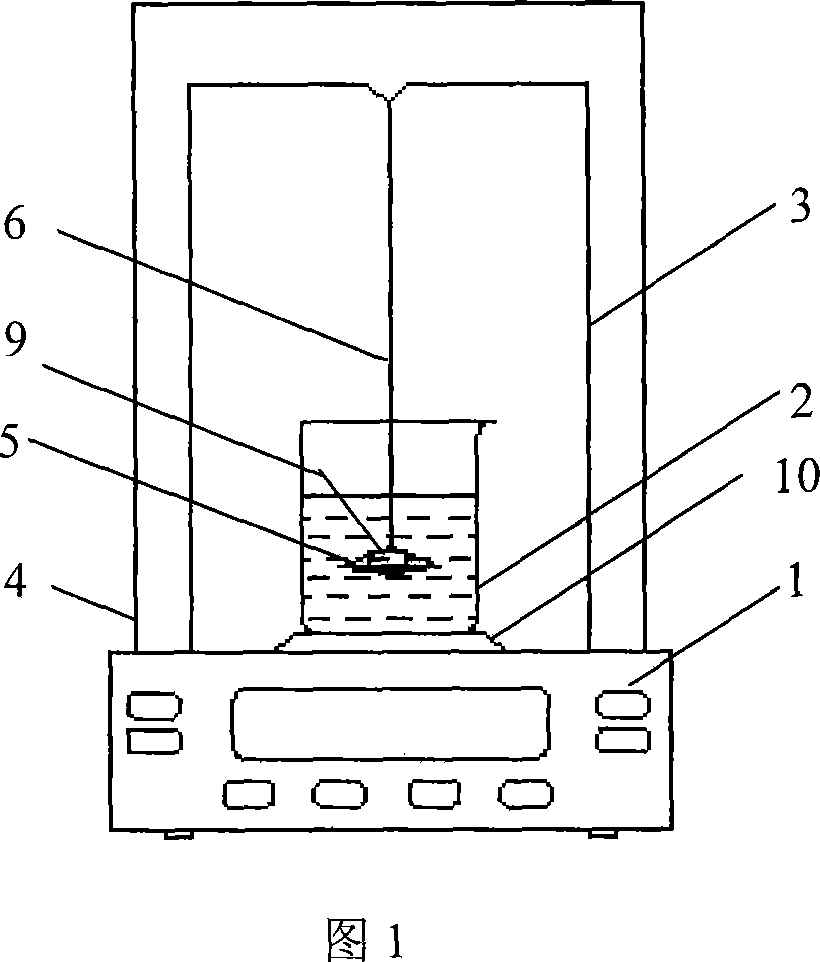

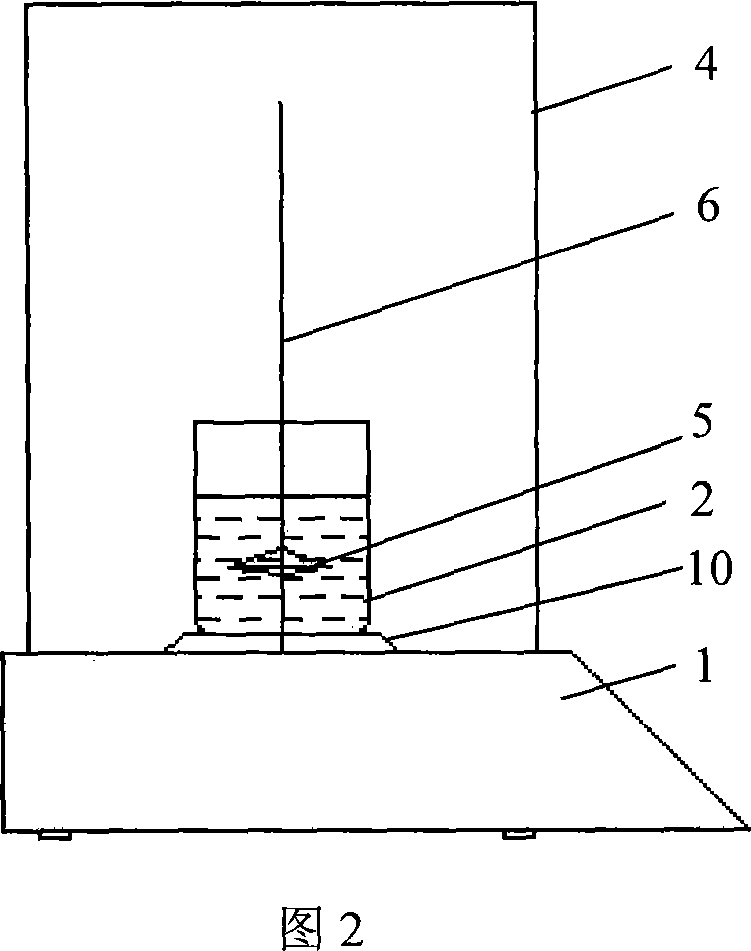

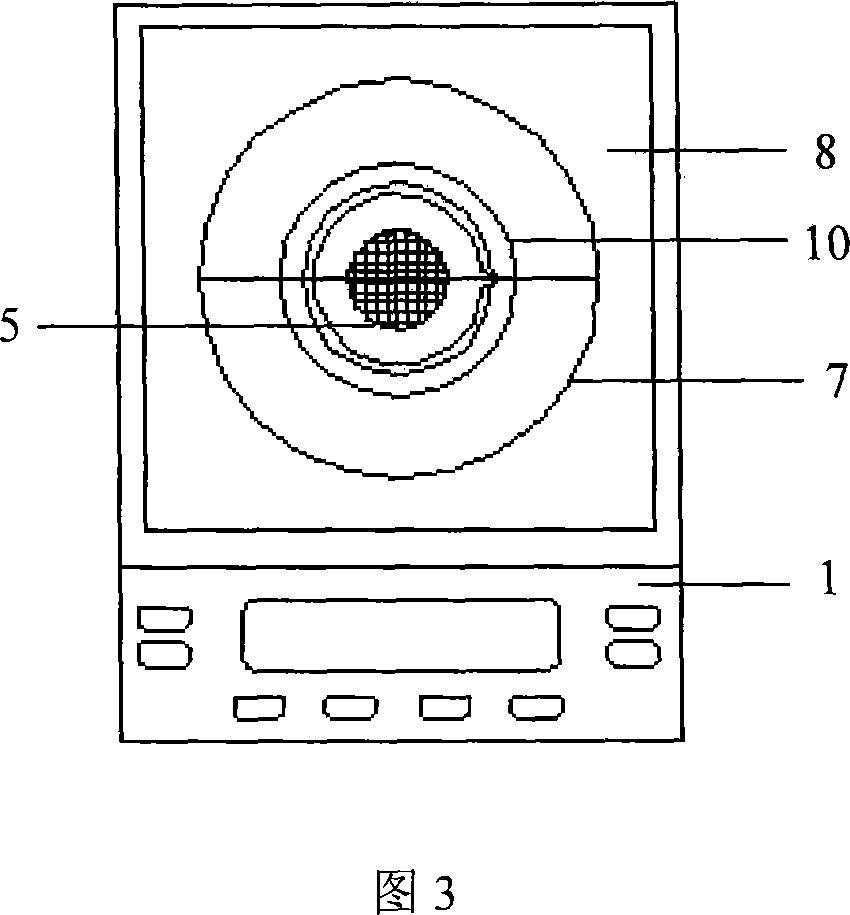

Electronic measuring equipment and method for ceramic volumetric density

InactiveCN101042323AImprove accuracySimple structureMaterial analysis by measuring buoyant forcesSpecial data processing applicationsMeasurement deviceCopper wire

This invention relates to one ceramics volume intensity electron measurement device and method, wherein the device comprises electron balance, water contain cup, thin copper wire and hanging barrel, wherein, the electron balance disc is put with cup and has one rack with its base socket to distribute loads onto load bench; thin copper wire top end is fixed onto rack and its down end has handing barrel in cup water; in measuring, setting the electron balance as zero and to rest ceramics quality m0 and then boiling it for two hours for natural cooling off; sweeping off water in the barrel to read balance display values to compute ceramics volume intensity.

Owner:SHANGHAI UNIV

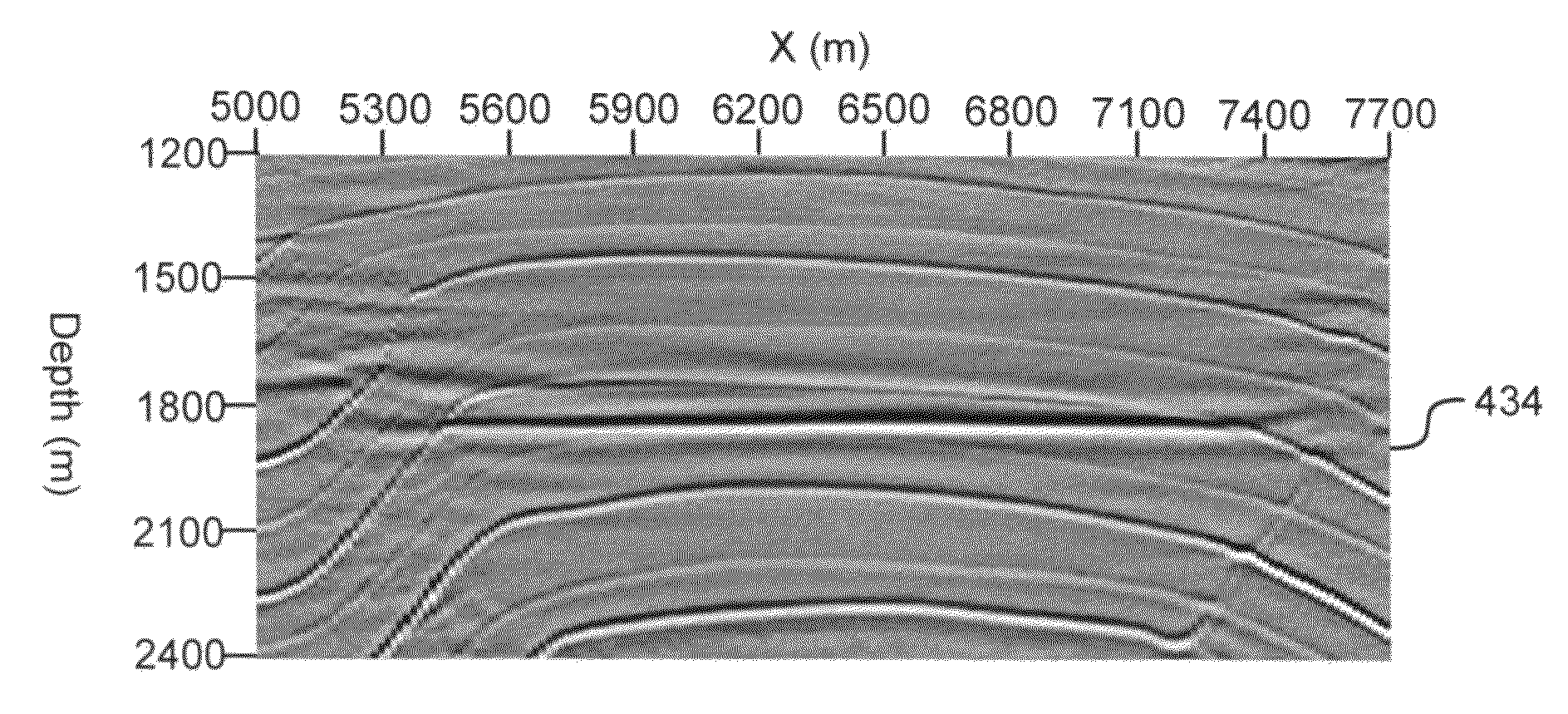

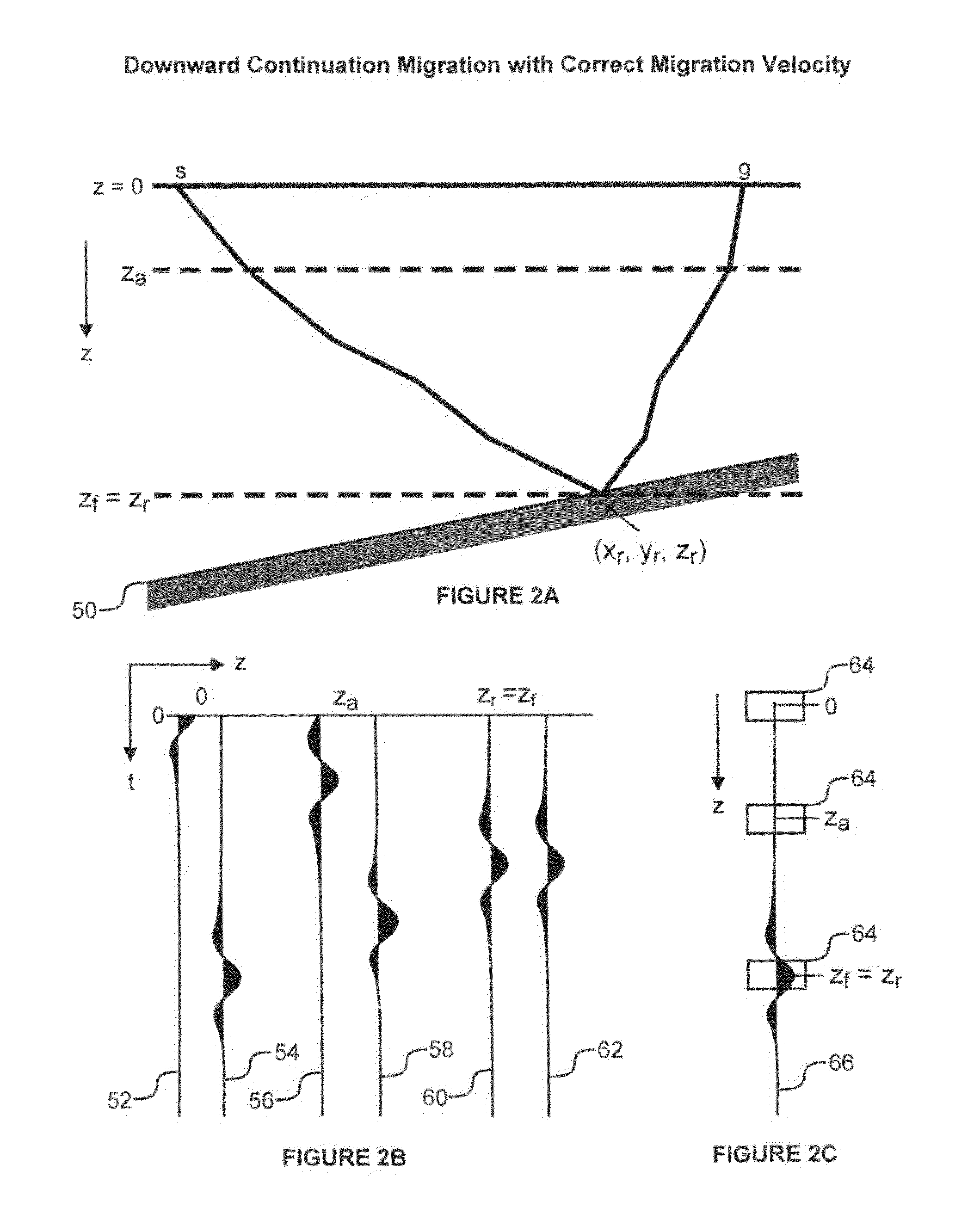

Methods and computer-readable medium to implement inversion of angle gathers for rock physics reflectivity attributes

InactiveUS20120095690A1Accurate measurementAccurate imagingGeomodellingSeismic signal processingS-waveVolumetric density

The invention relates to methods and computer-readable medium to determine seismic reflectivity attributes indicating the presence of hydrocarbons in earth. In several embodiments, the methods and computer-readable medium perform the steps of computing seismic reflectivity attributes includes inputting data representing reflected seismic waves and a volume of P-wave velocity, transforming the volume of P-wave velocity into a volume of bulk density, transforming the volume of P-wave velocity into a volume of S-wave velocity using amplitude information from the reflected seismic waves, and using the volume of S-wave velocity and the volume of P-wave velocity to compute the reflectivity attribute.

Owner:HWH APPS LLC

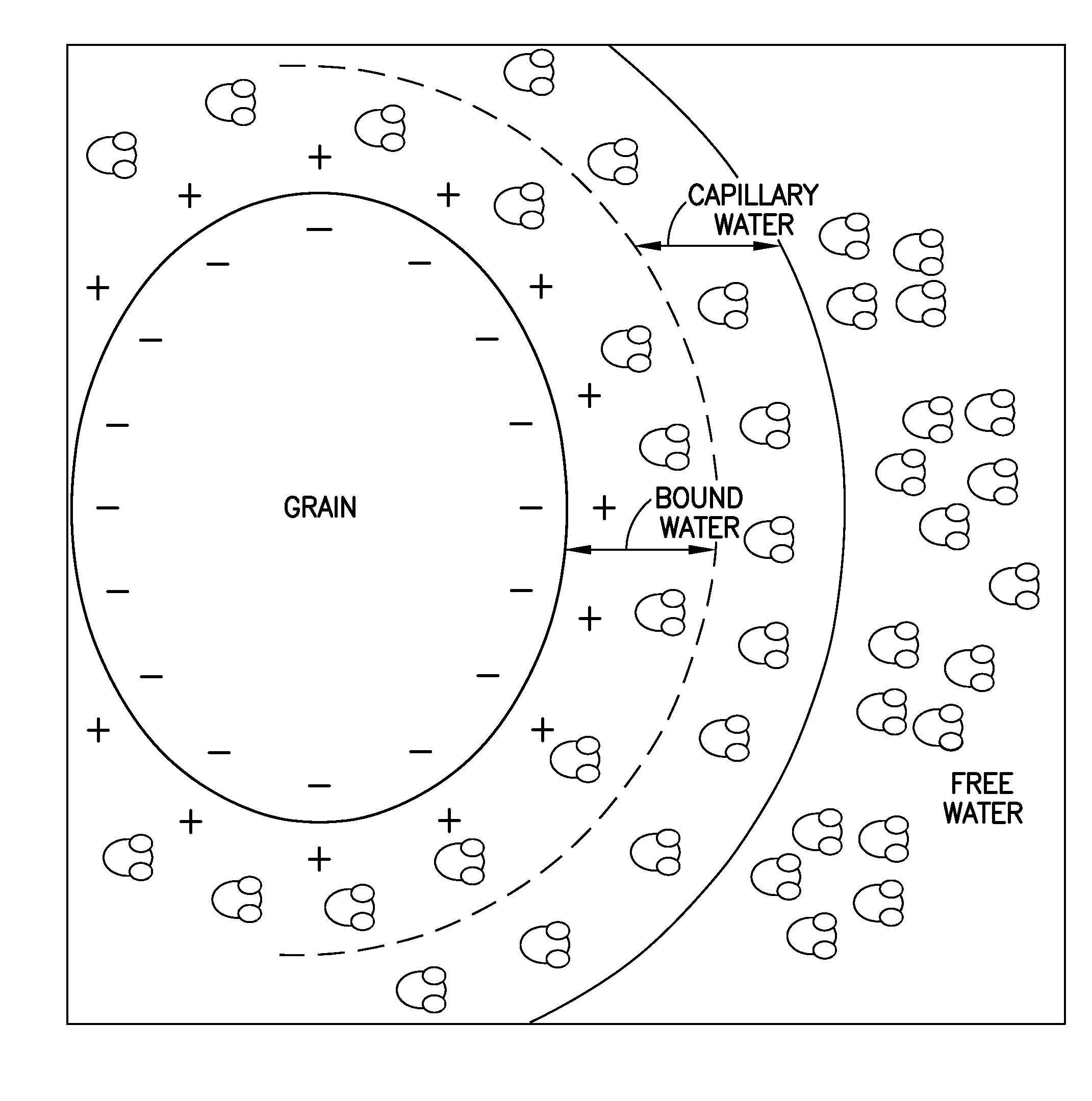

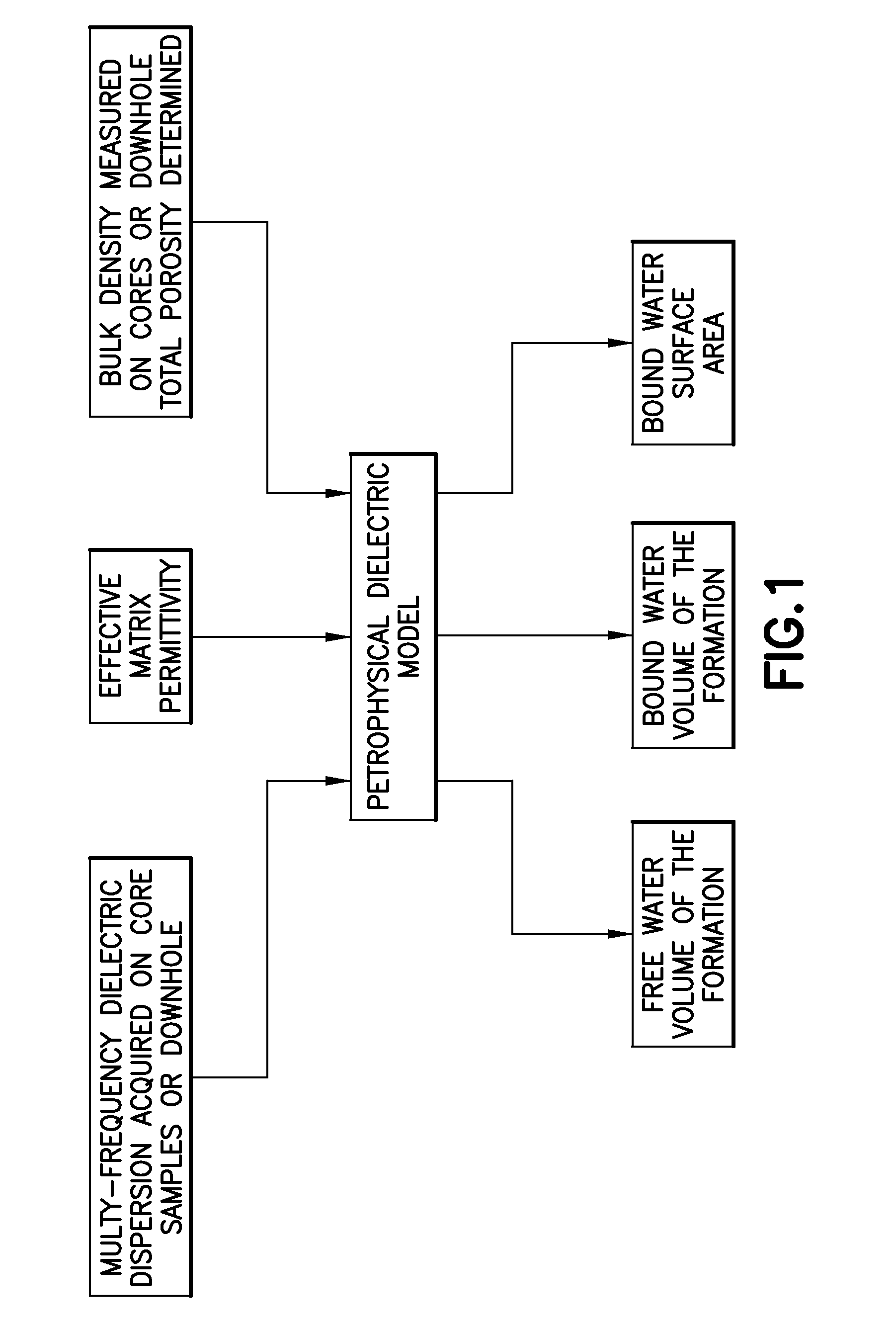

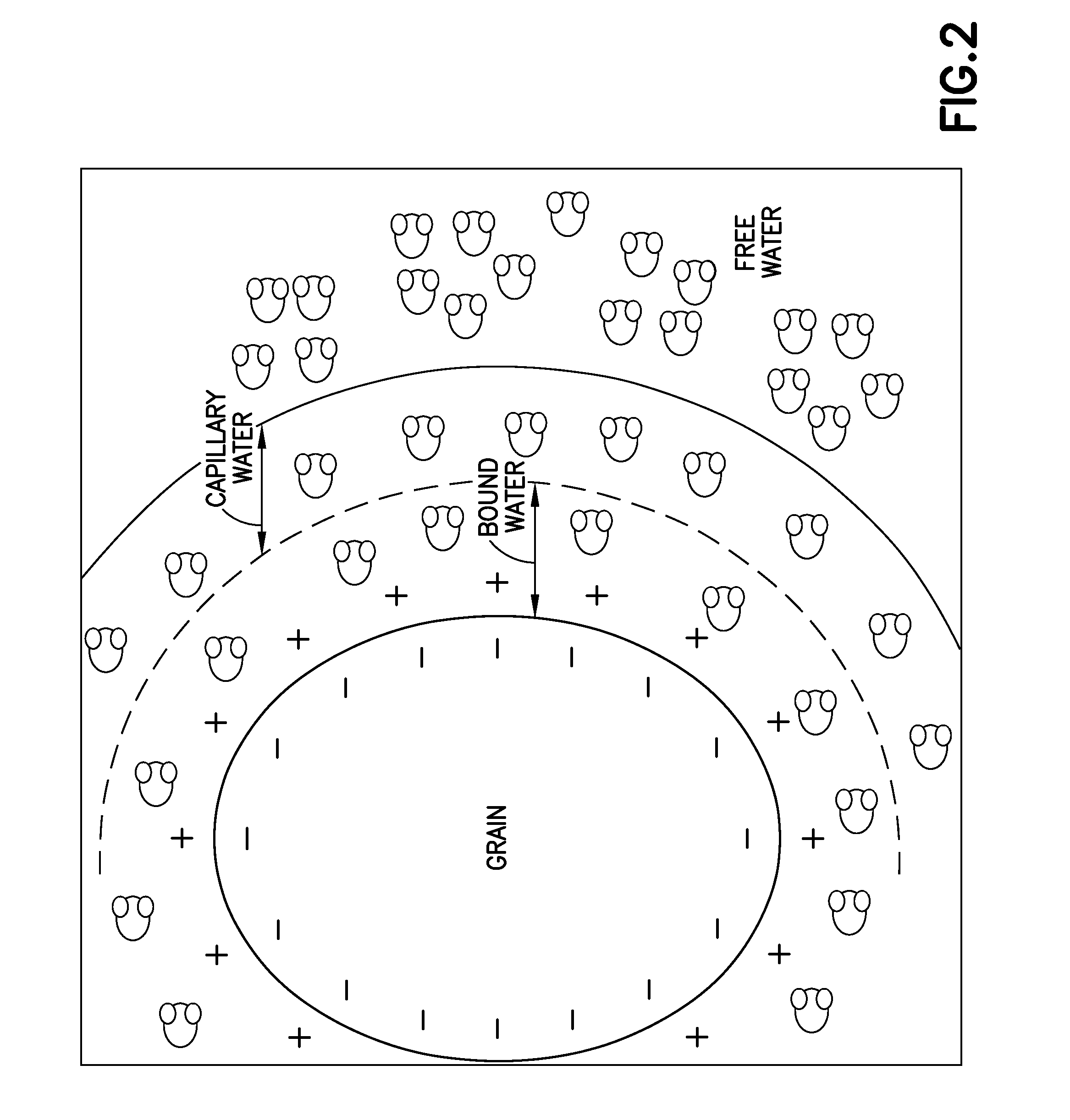

Downhole Wettability Estimate Using Multi-Frequency Dielectric Measurements

The wettability of a formation may be estimated using a multi-frequency dielectric measurement tool. Multi-frequency dielectric dispersion measurements are made using the multi-frequency dielectric measurement tool on a sample. The bulk density and the total porosity of the sample are also otherwise acquired. The bulk density, matrix permittivity, total porosity, and multi-frequency dielectric dispersion measurements are input into a petrophysical dielectric model and the petrophysical dielectric model is applied to obtain inversion results. A wettability state of the sample is determined using the inversion results and one or more reservoir management decisions are made based on the determined wettability state of the sample. A non-transitory, computer-readable storage medium may be provided that has stored on it one or more programs that provide instructions. The instructions are executed by a processor and cause the processor to develop an estimation of formation wettability that may be used for reservoir management.

Owner:SCHLUMBERGER TECH CORP

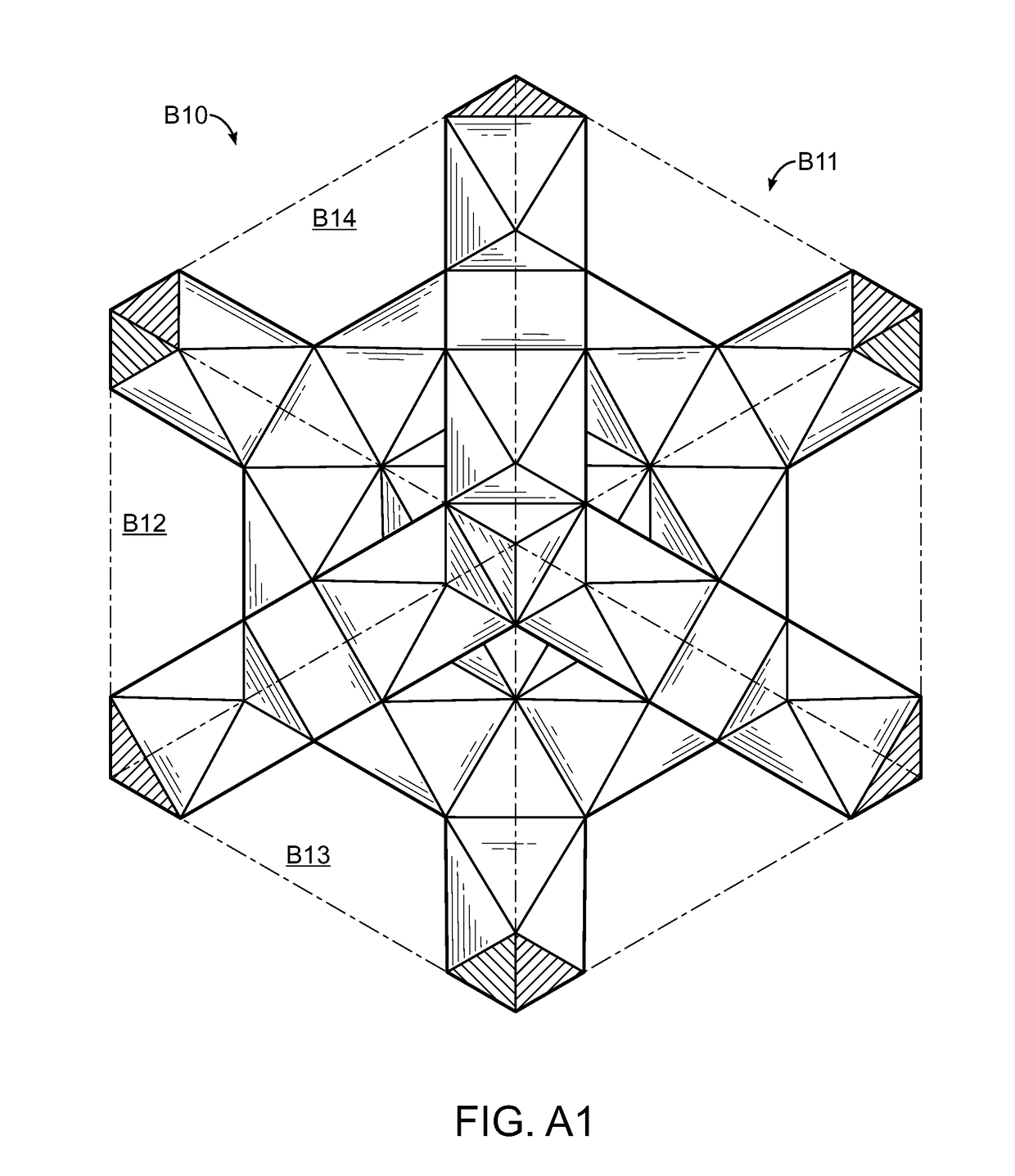

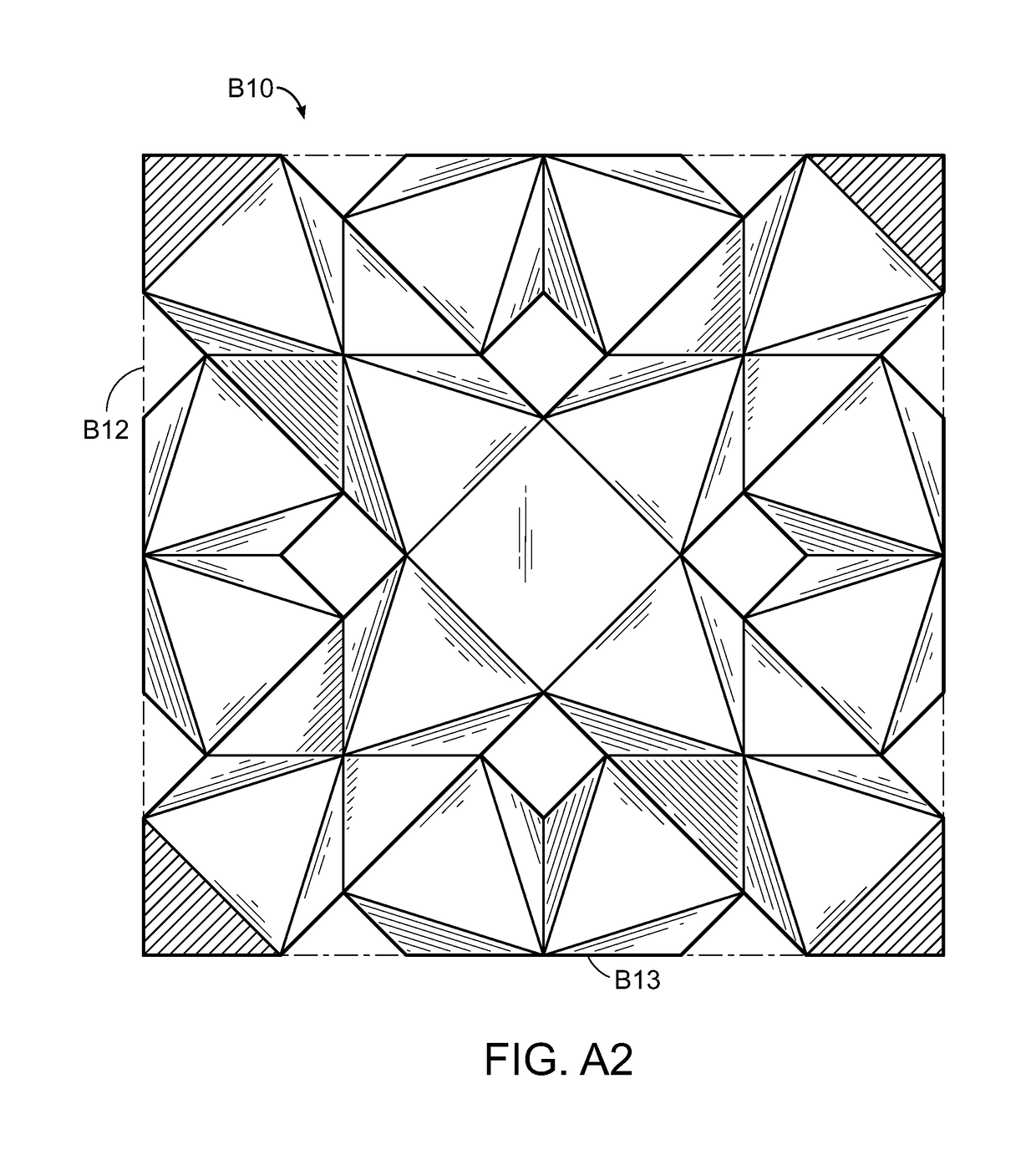

Features for Implants with a Reduced Volumetric Density of Surface Roughness

PendingUS20180243094A1Avoid damageEasy to separateAdditive manufacturing apparatusBone implantDistractionAxial compression

The invention disclosed herein includes implant features that can be used, in some embodiments, on devices with a volumetric density of less than about 100 percent and devices with a surface roughness of some value. The implant features include one or more protrusions mounted on the forward edge of an implant that can ease the distraction of tissue during implantation and reduce the occurrence of damage during a manufacturing process. In some embodiments, the protrusions have gaps in a non-axial direction with respect to the implant to allow axial compression with respect to the protrusions. In some embodiments, the protrusions have a circumferential gap between them and a body of a device to reduce any impact on the device's elastic modulus.

Owner:NANOHIVE MEDICAL LLC

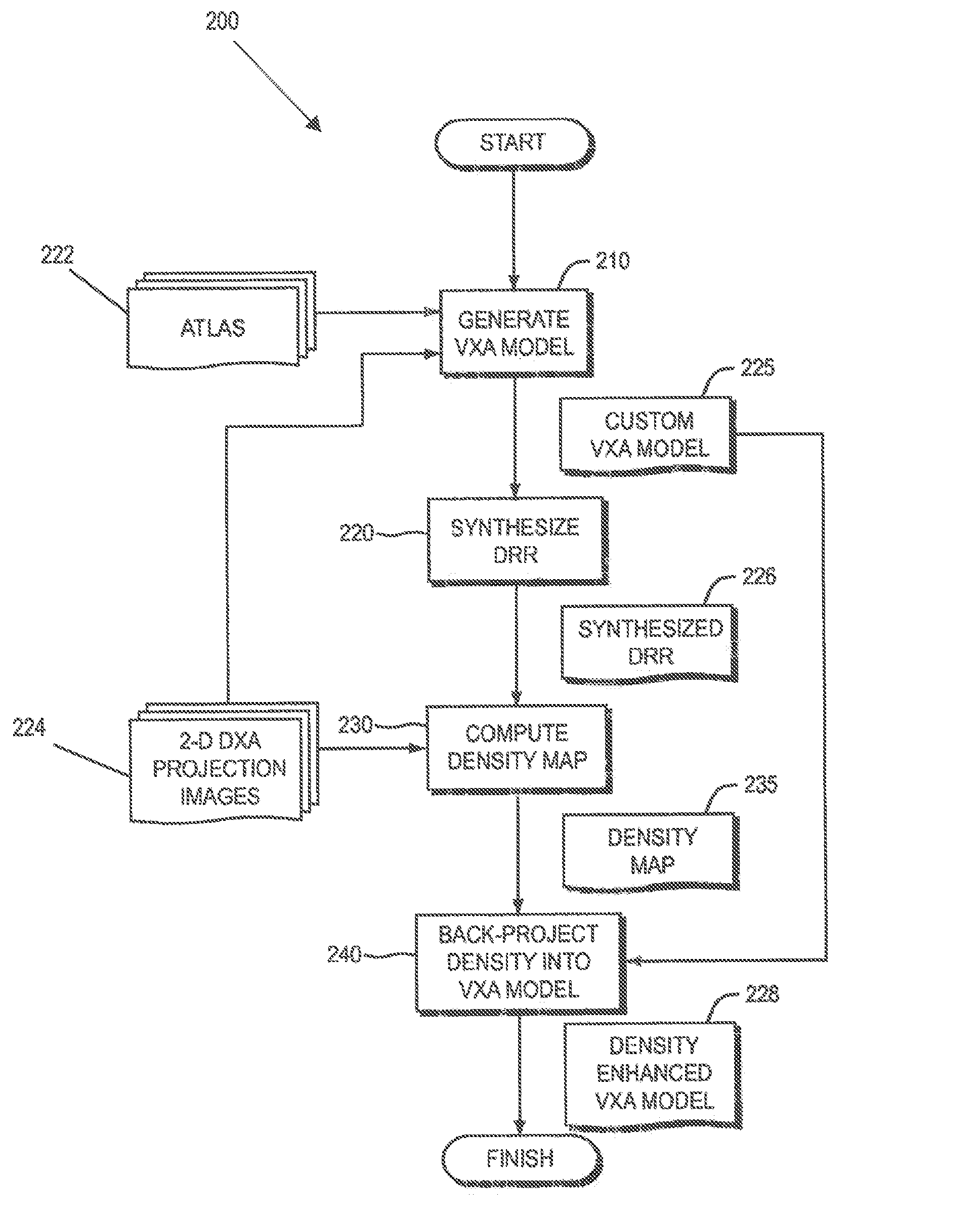

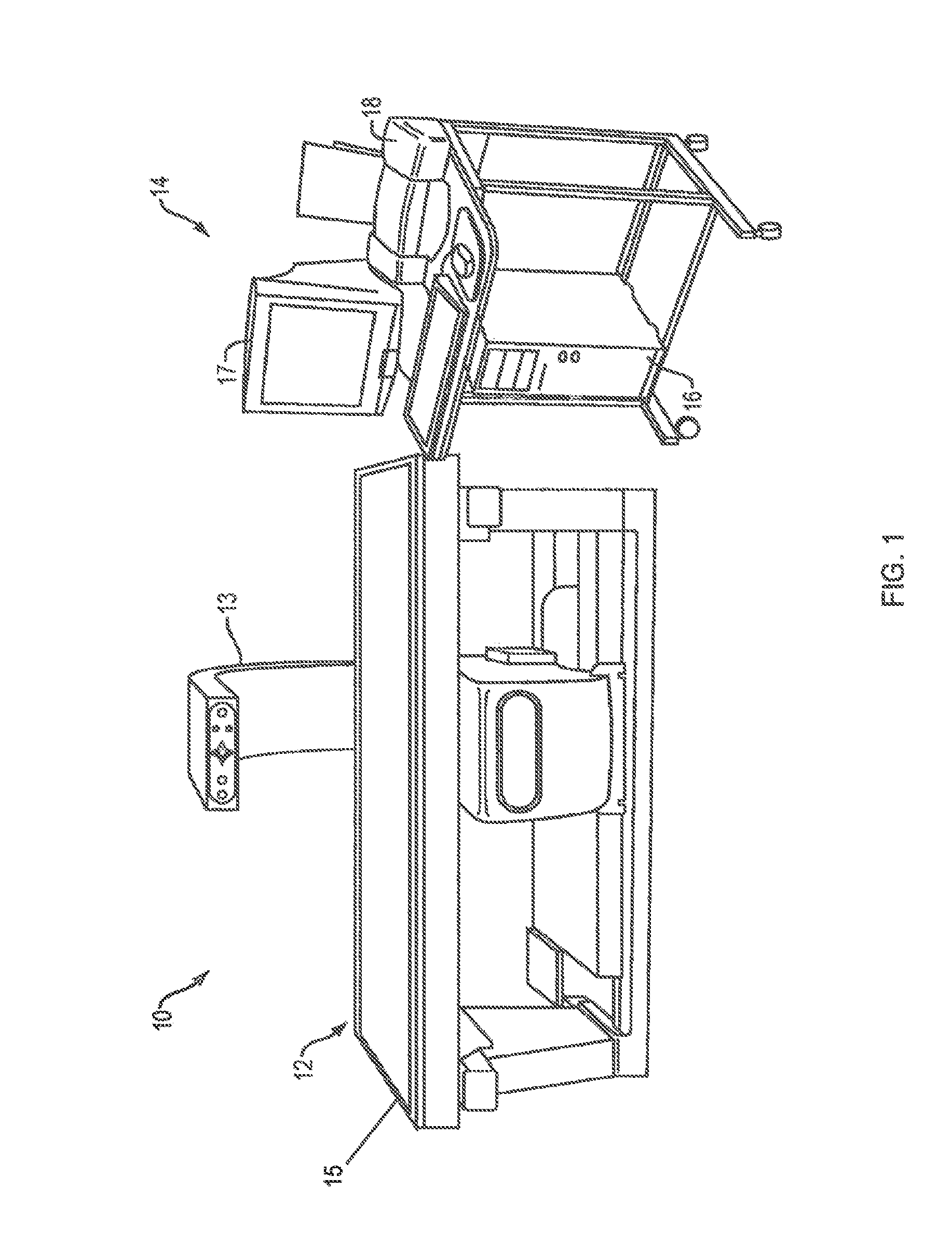

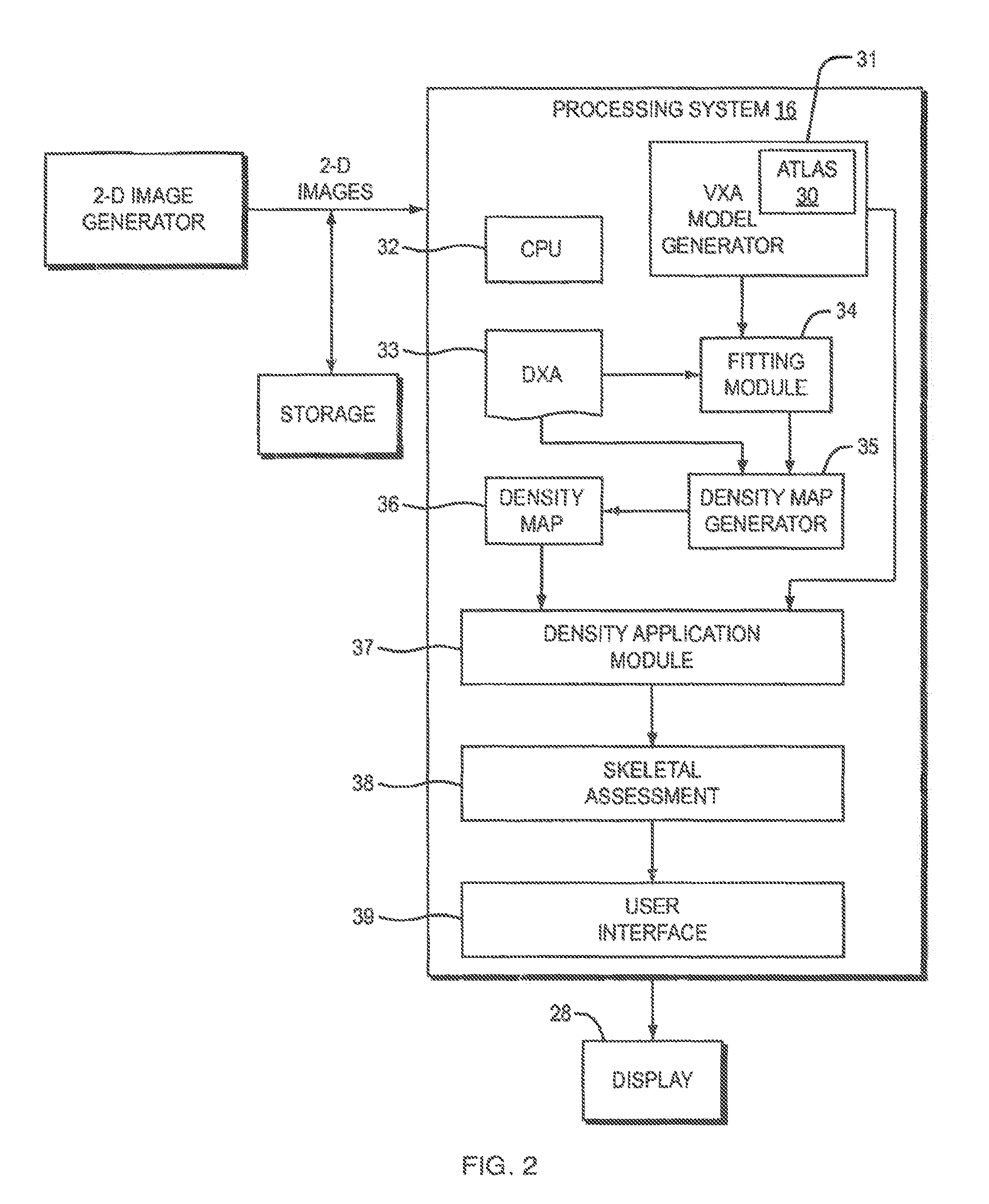

System and method for generating enhanced density distribution in a three dimensional model of a structure for use in skeletal assessment using a limited number of two-dimensional views

ActiveUS8693634B2Low costReduce exposureMedical simulationReconstruction from projectionProjection imageDensity distribution

A method of generating a density enhanced model of an object is described. The method includes generating a customized a model of an object using a pre-defined set of models in combination with at least one projection image of the object, where the customized model is formed of a plurality of volume elements including density information. A density map is generated by relating a synthesized projection image of the customized model to an actual projection image of the object. Gains from the density map are back-projected into the customized model to provide a density enhanced customized model of the object. Because the density map is calculated using information from the synthesized projection image in combination with actual projection images of the structure, it has been shown to provide spatial geometry and volumetric density results comparable to those of QCT but with reduced patient exposure, equipment cost and examination time.

Owner:HOLOGIC INC

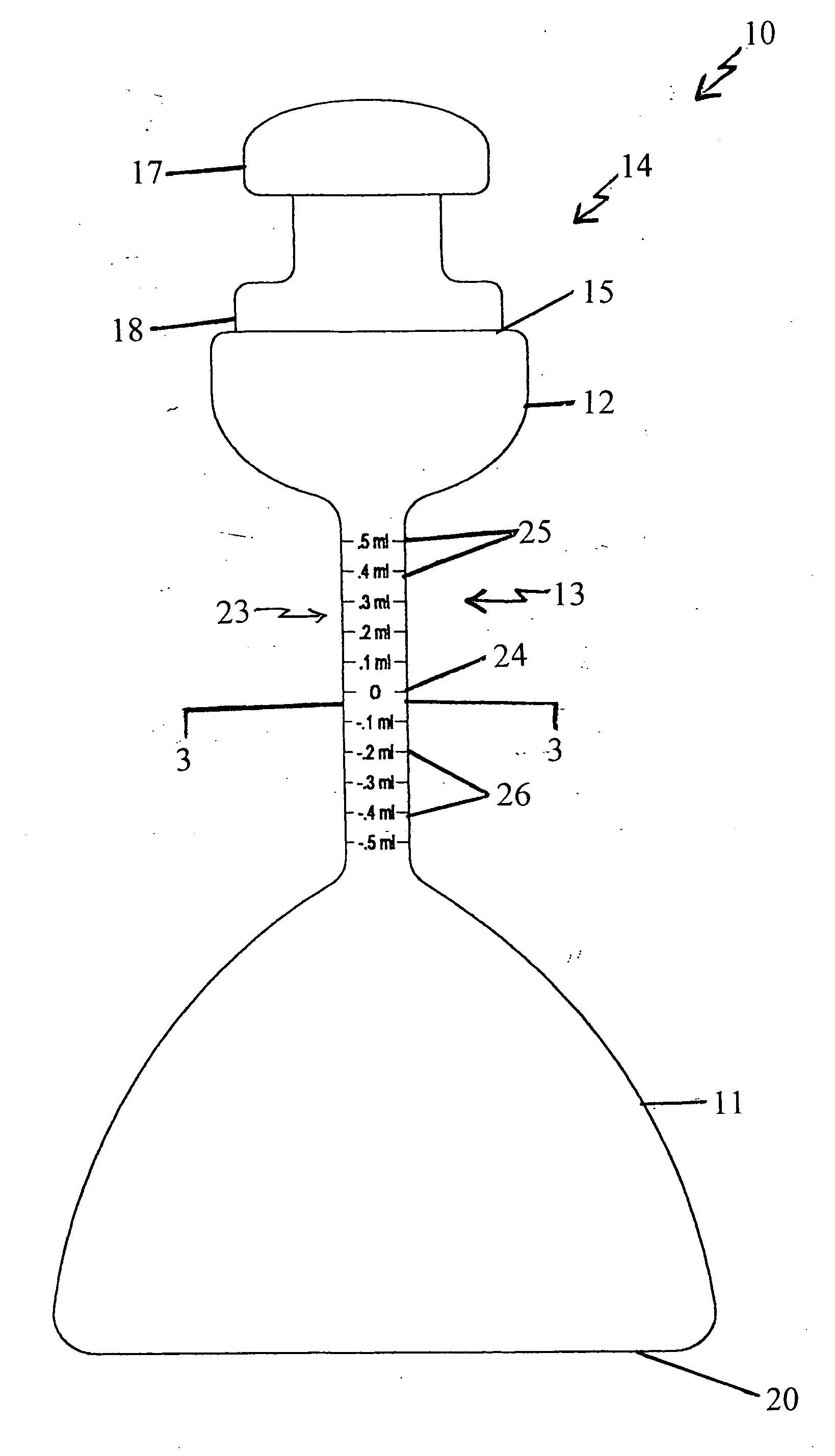

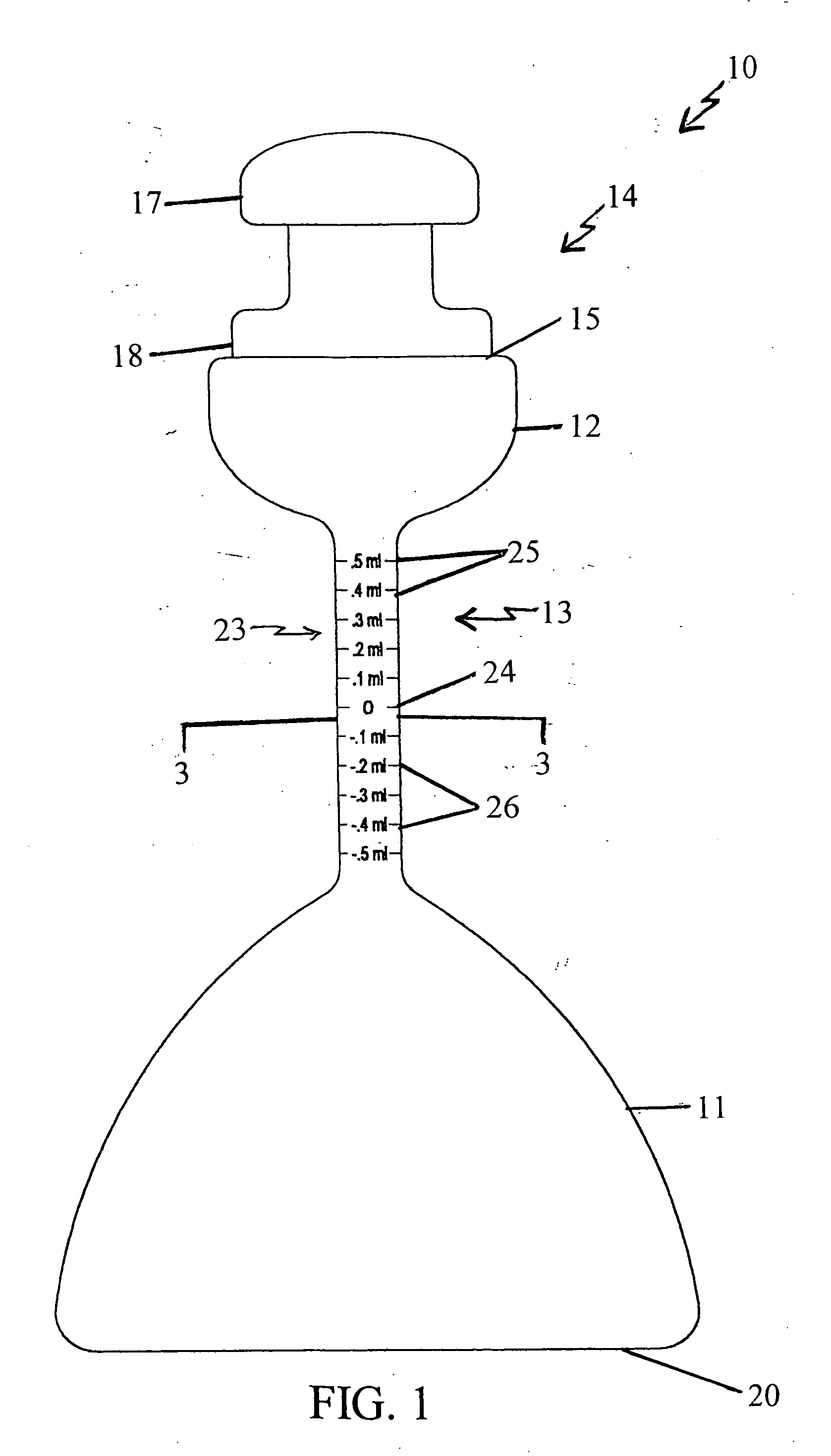

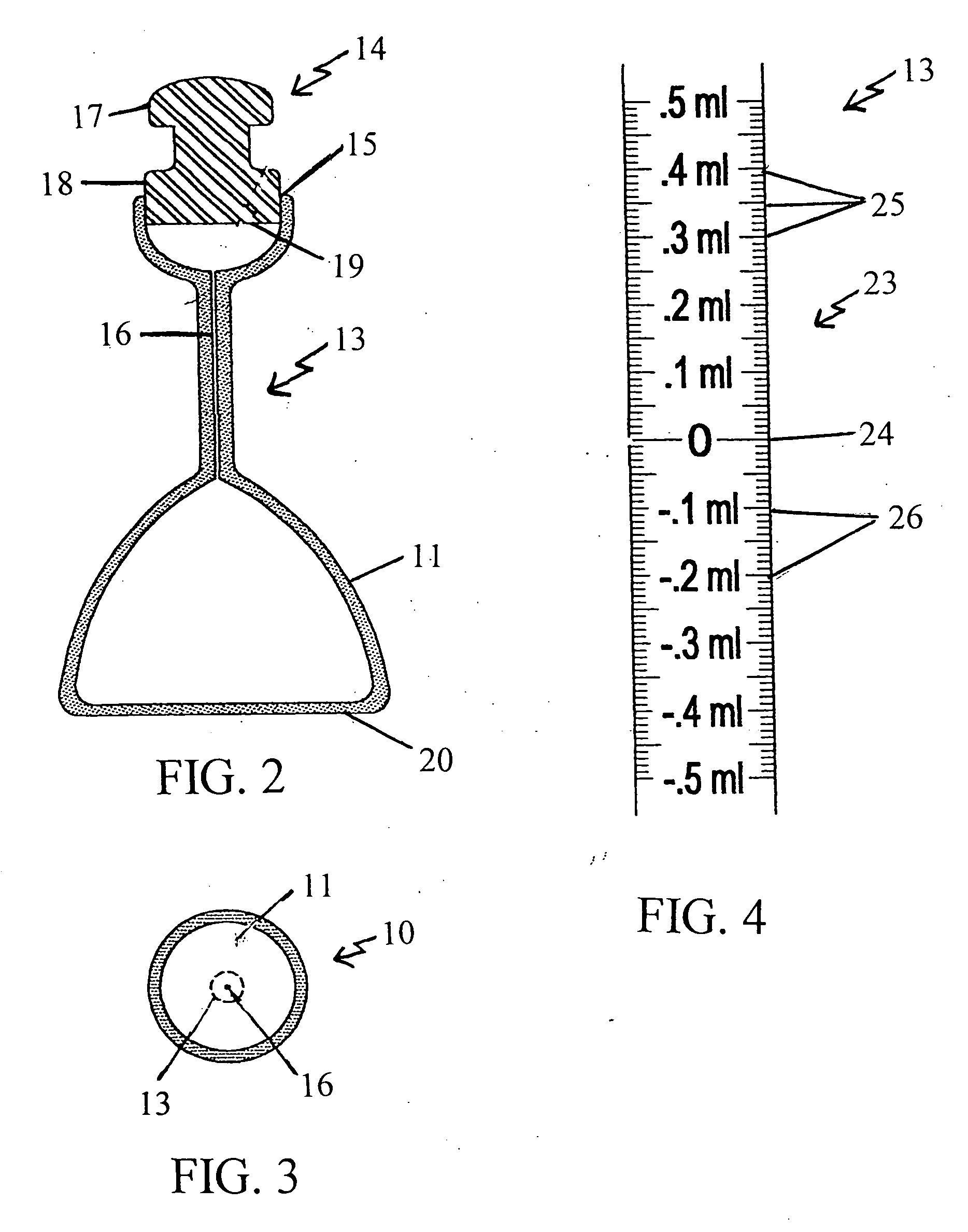

Volumetric densiometer flask

InactiveUS20060185421A1Accurate measurementRapid scale-upSpecific gravity using flow propertiesContainer/cavity capacity measurementMedicineVolumetric density

A volumetric densiometer flask for determining the volumetric density of a solute includes: (a) a first bulbous portion in a lower end section of the flask; (b) a second bulbous portion in an upper end section of the flask, the second bulbous portion comprising an open mouth at its upper end; (c) a central neck comprising a central channel in open communication with the first bulbous portion at an upper end of the neck, and the second bulbous portion at an opposite, lower end of the neck; and (d) a removable stopper that is closely insertable into the mouth of the second bulbous portion, the mouth being correspondingly sized to a lower end of the stopper. Also included herein is a procedure for determining the volumetric density of a given sample using the volumetric densiometer flask.

Owner:WALKER STEPHAN HOWARD

Low-cost, low-density and high-CaO corundum castable and preparation method thereof

The invention relates to a low-cost, low-density and high-CaO corundum castable and a preparation method thereof. The low-cost, low-density and high-CaO corundum castable is prepared by adding industrial alumina powder on the basis of the conventional common corundum castable. Volume expansion caused by calcium hexaluminate generated in the corundum castable is compensated by using volume contraction caused by phase change of industrial alumina at a high temperature, so that the contradiction between the adding amount of cement and the volume stability of the castable is solved successfully. The invented castable has low volume density and low thermal conductivity coefficient, energy loss caused by the application of the castable to a high-temperature kiln can be reduced, and the aim of saving energy is fulfilled. The industrial alumina powder is added, so that the cost of the castable is reduced in a certain degree, and the competitive advantage of the castable is enhanced. The corundum castable prepared with the method can be widely applied in the high-temperature industrial fields of steel and iron, non-ferrous metals, ceramics, petrifaction, and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Scalable mass data storage device

ActiveUS8397011B2Improve data transfer rateHigh bulk densityEnergy efficient ICTMemory adressing/allocation/relocationData centerVolumetric density

A scalable data storage device which includes non-volatile memory uses a networked bus system which can be employed on a single memory storage chip level or in a multi-chip package (MCP). The scalable data storage device uses data routing modules which are adapted to store incoming data and send outgoing data thereby providing decoupling of the networked buses. This arrangement enables significantly higher data transfer rates, surpassing DRAM SSDs at a fraction of the size and cost, provides increased volumetric density (1 TB in less than 1 cubic inch), and permits concurrency of operations. The scalable data storage device can be engineered to have a rewrite capability of over 500 times that of Flash RAM and can scale down to 8 bits and up to exabytes, yottabytes and beyond. The scalable data storage device may be used in a wide range of applications from large data centers to small consumer electronic products.

Owner:STACKSPEED INC +1

Beta-spodumene-cordierite composition, article, and method

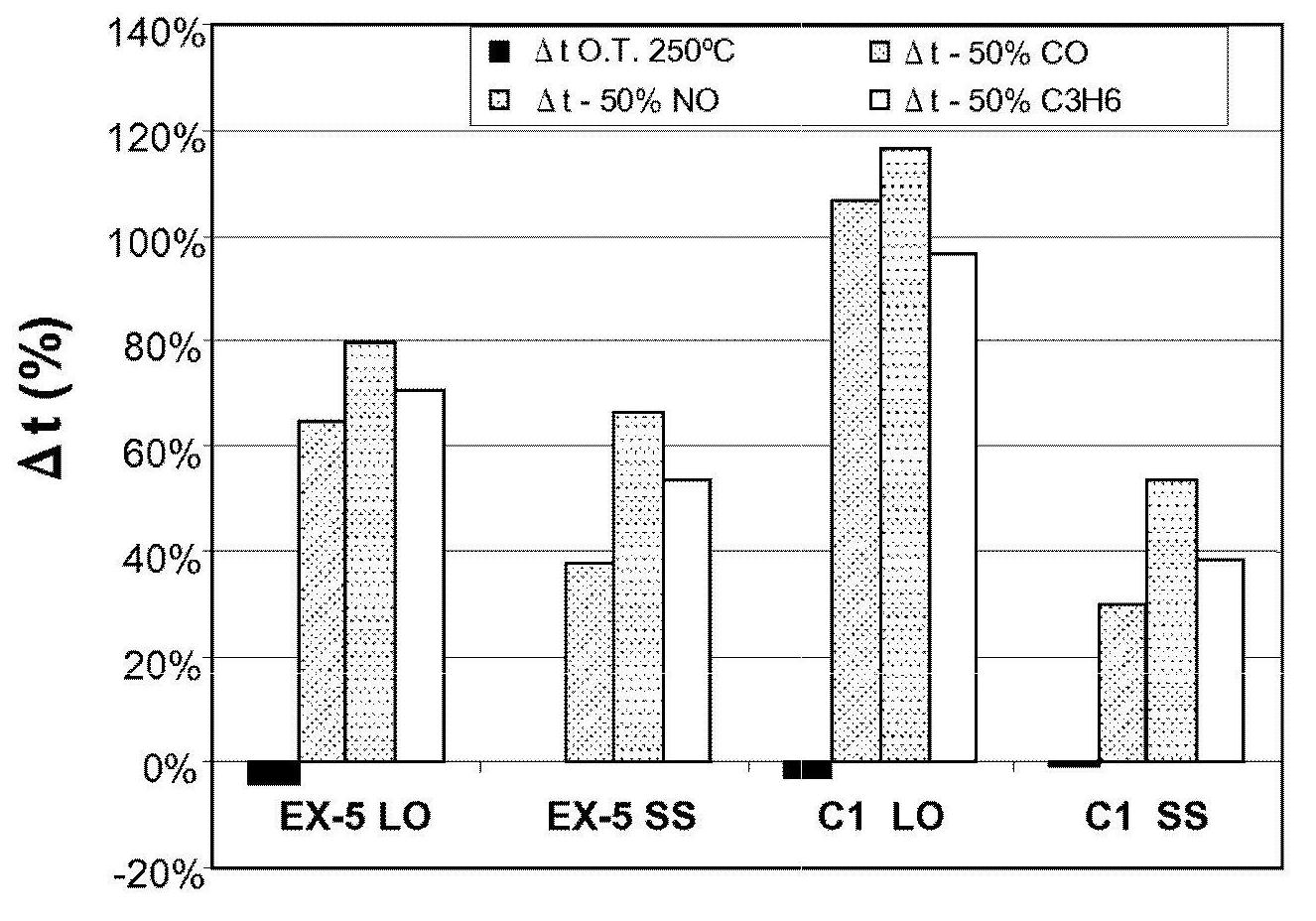

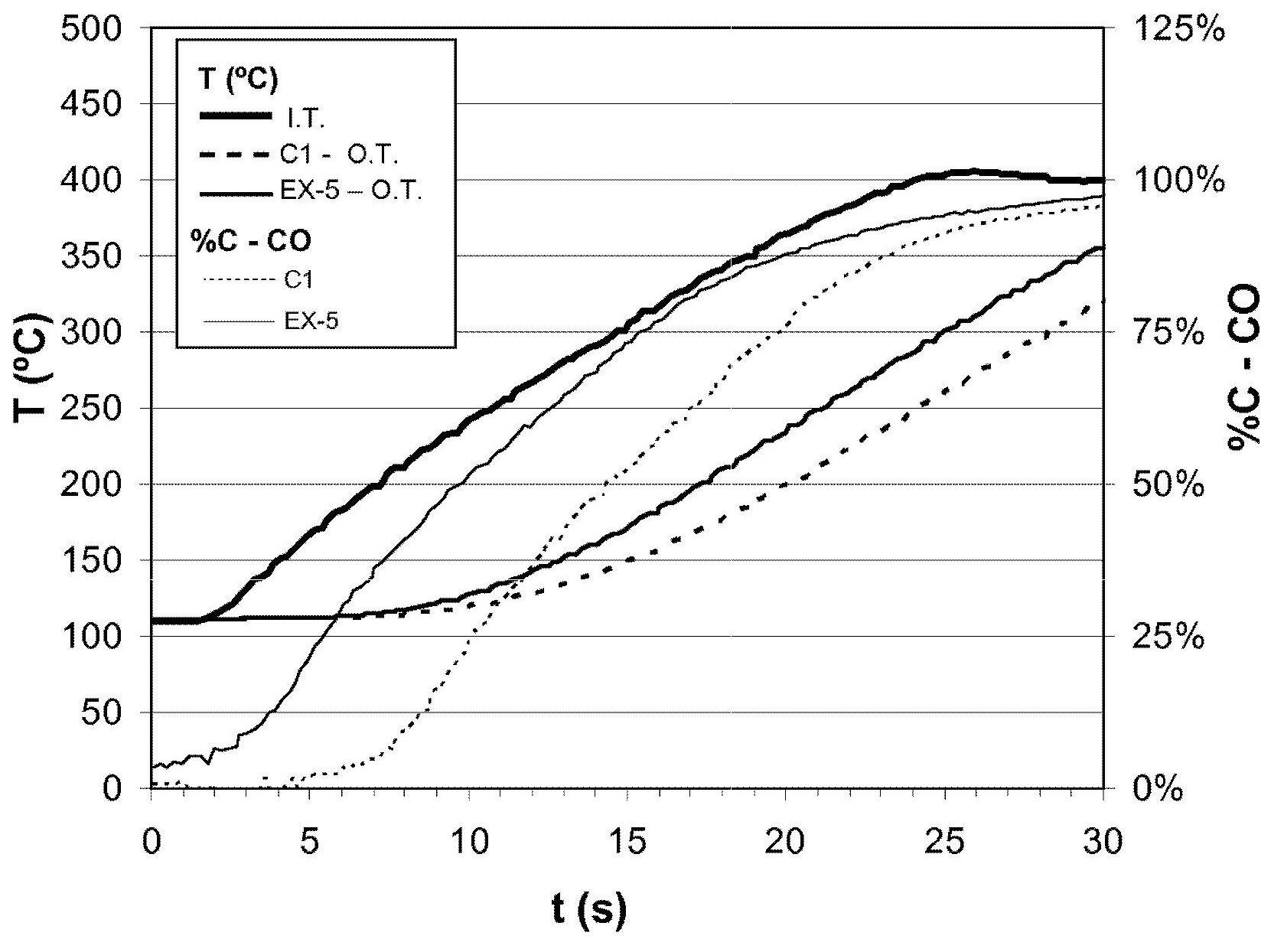

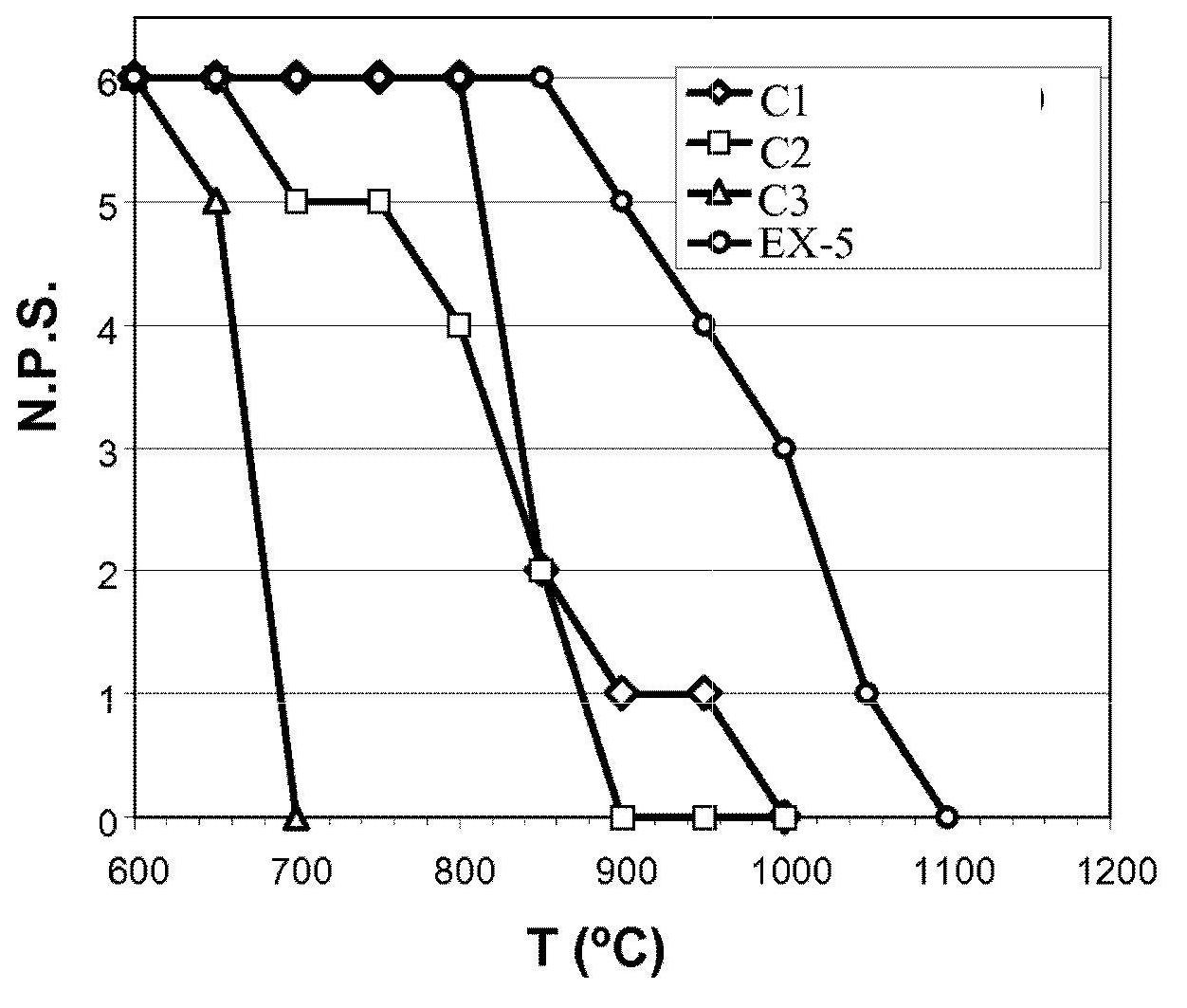

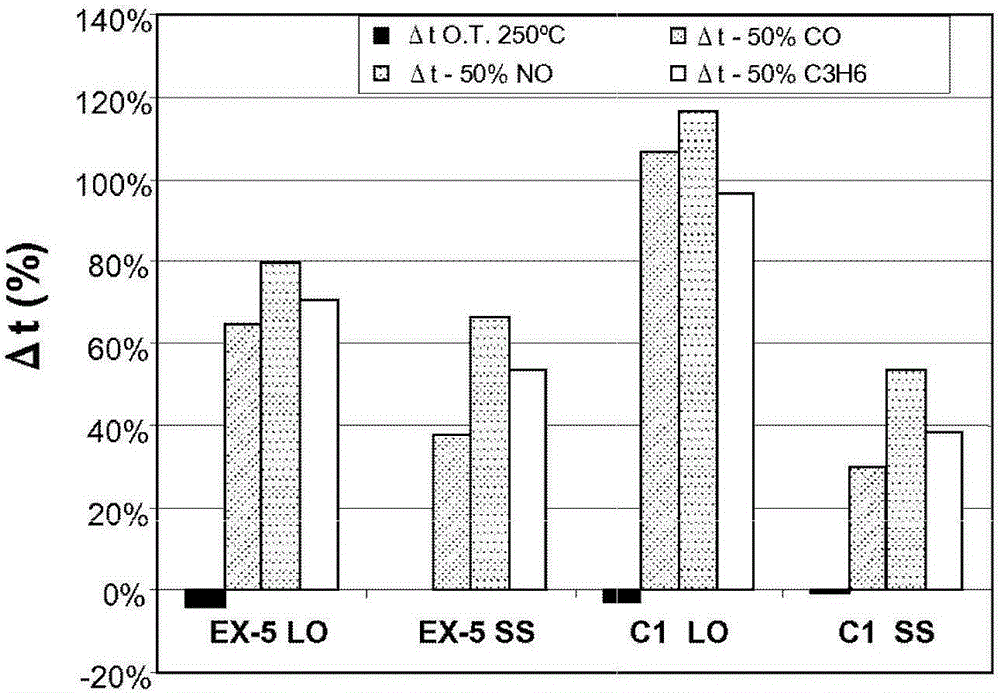

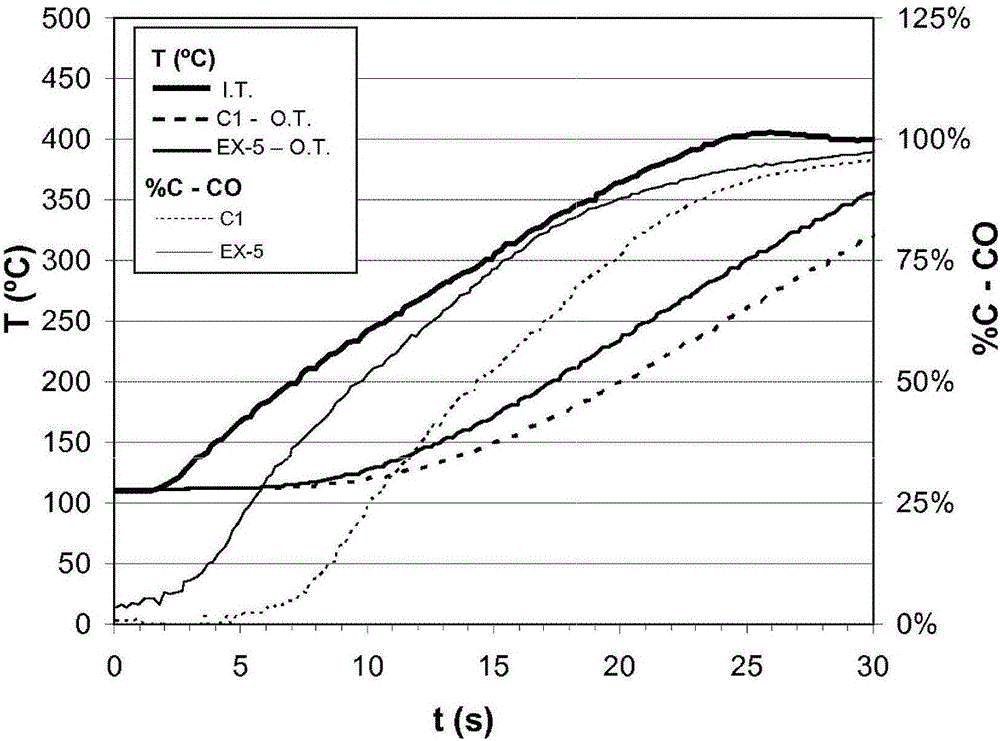

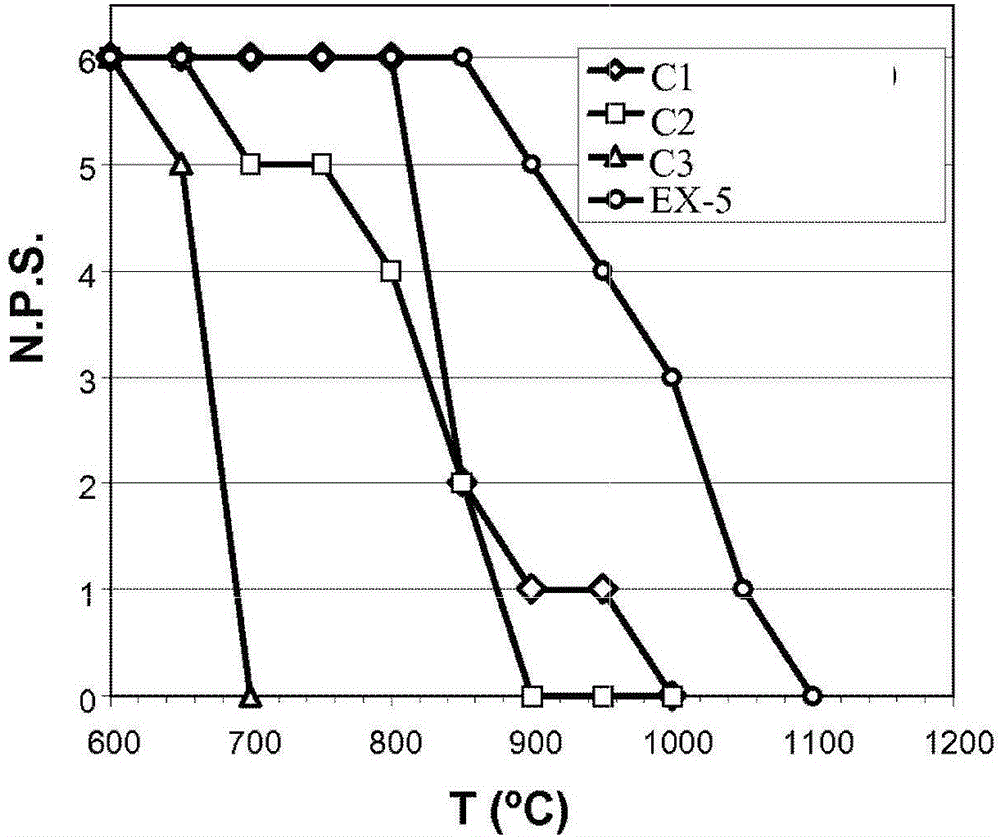

Porous spodumene-cordierite honeycomb bodies of high strength but low volumetric density, useful for the manufacture of close-coupled engine exhaust converters, gasoline engine particulate exhaust filters, and NOx integrated engine exhaust filters, are provided through the reactive sintering of batches comprising sources of magnesia, alumina and silica together with a lithia source, such as a spodumene or petalite ore.

Owner:CORNING INC

Measurement method for volumetric weight of ore

InactiveCN106990019AShorten test timeReduce stepsMaterial analysis by measuring buoyant forcesVolumetric densityMineralogy

Belonging to the technical field of ore exploration, the invention discloses a measurement method for volumetric weight of ore. The method includes: firstly correcting a high precision electronic scale with a standard volumetric weight and a standard rock core sample, then measuring the weight of P1 of a dry ore sample in the air directly on the high precision electronic scale, and measuring the weight P2 of a wet ore sample in water by hanging the ore sample on the high precision electronic scale and then putting the ore sample into water for weighing, performing stress analysis to know that the ore is under the action of gravity and buoyancy in water, and carrying out calculation to obtain the volumetric weight of ore. The technical scheme provided by the invention reduces the tedious operation process of existing technological means, and calculates the volumetric weight of ore through direct measurement of weight of ore sample in the air and the weight in water. According to the technical scheme, testing of each sample can be completed within 5min, therefore the testing time of each sample can be greatly shortened, and the detection efficiency of the volumetric weight of ore is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Combining Multiple Energy X-Ray Imaging And Well Data To Obtain High-Resolution Rock, Mechanical, And Elastic Property Profiles

InactiveUS20180164470A1Material analysis using wave/particle radiationNuclear radiation detectionHigh-resolution computed tomographyX-ray

A method is provided for evaluating a geological formation which integrates well data and high resolution computed tomography of rock samples thereof. Relationships are determined for a formation between a formation property, such as an elastic property, and at least one of photoelectric effect index (PEF), effective atomic number (Zeff), and bulk density (RHOB), using well data, and tomographic imaging is used to determine at least one of the latter mentioned properties (PEF, Zeff, RHOB) at higher resolution, which can be used in the relationship to determine a corresponding formation property. This affords an opportunity to develop formation property data for more challenging formations to evaluate, such as thinly laminated formations or others. Computerized systems, computer program products on non-transitory computer usable storage media, and programs for performing the methods are also provided.

Owner:HALLIBURTON ENERGY SERVICES INC

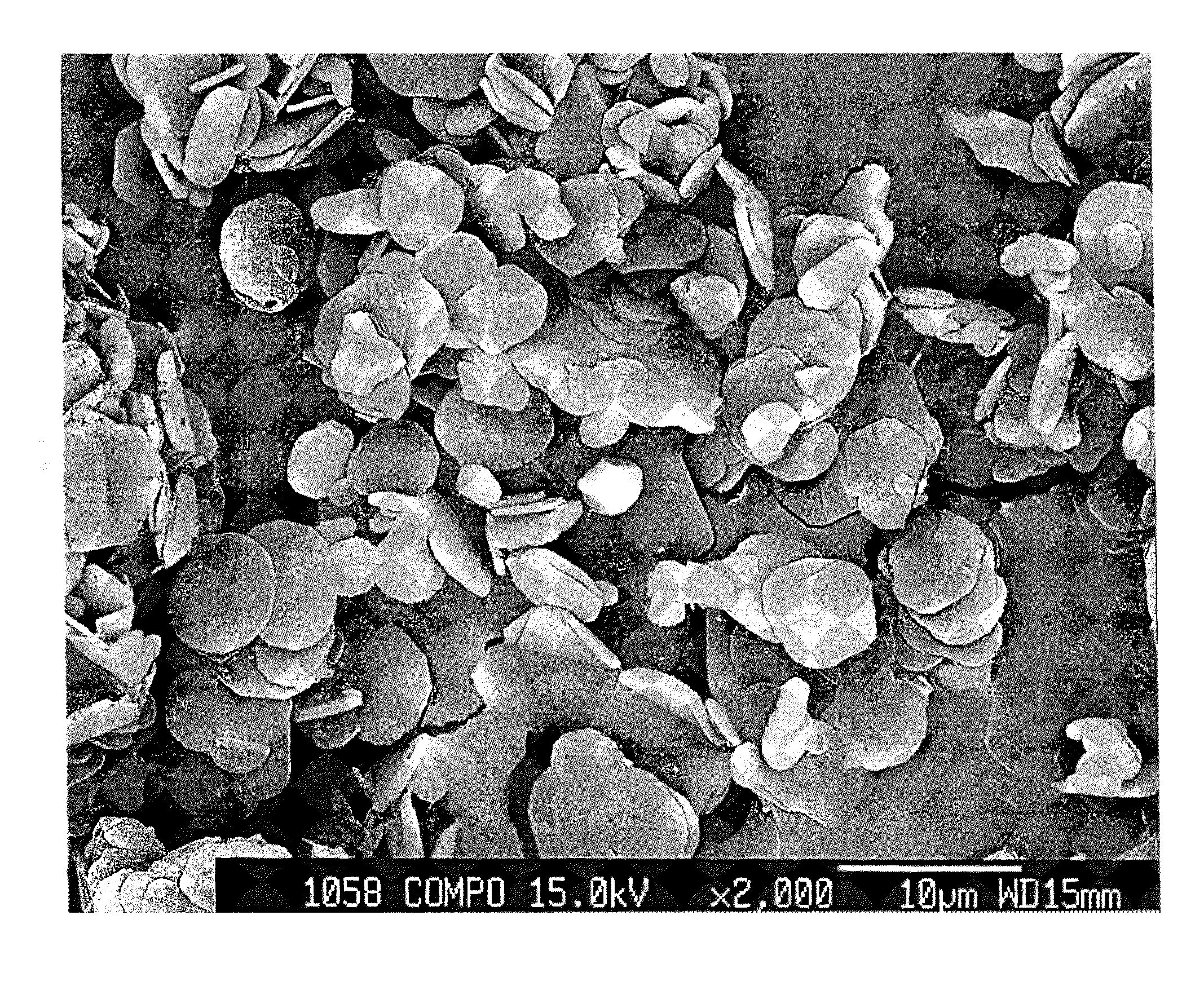

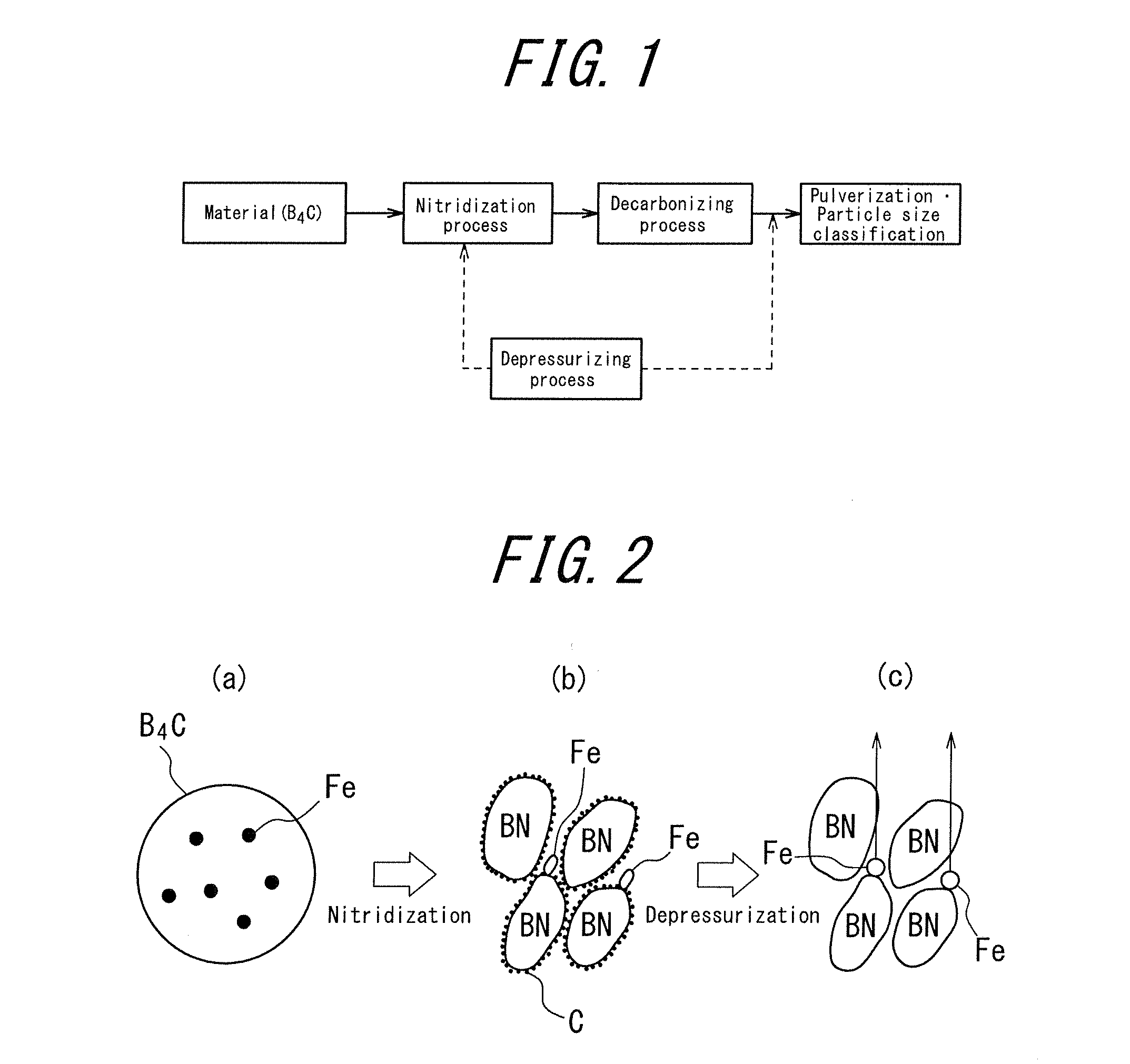

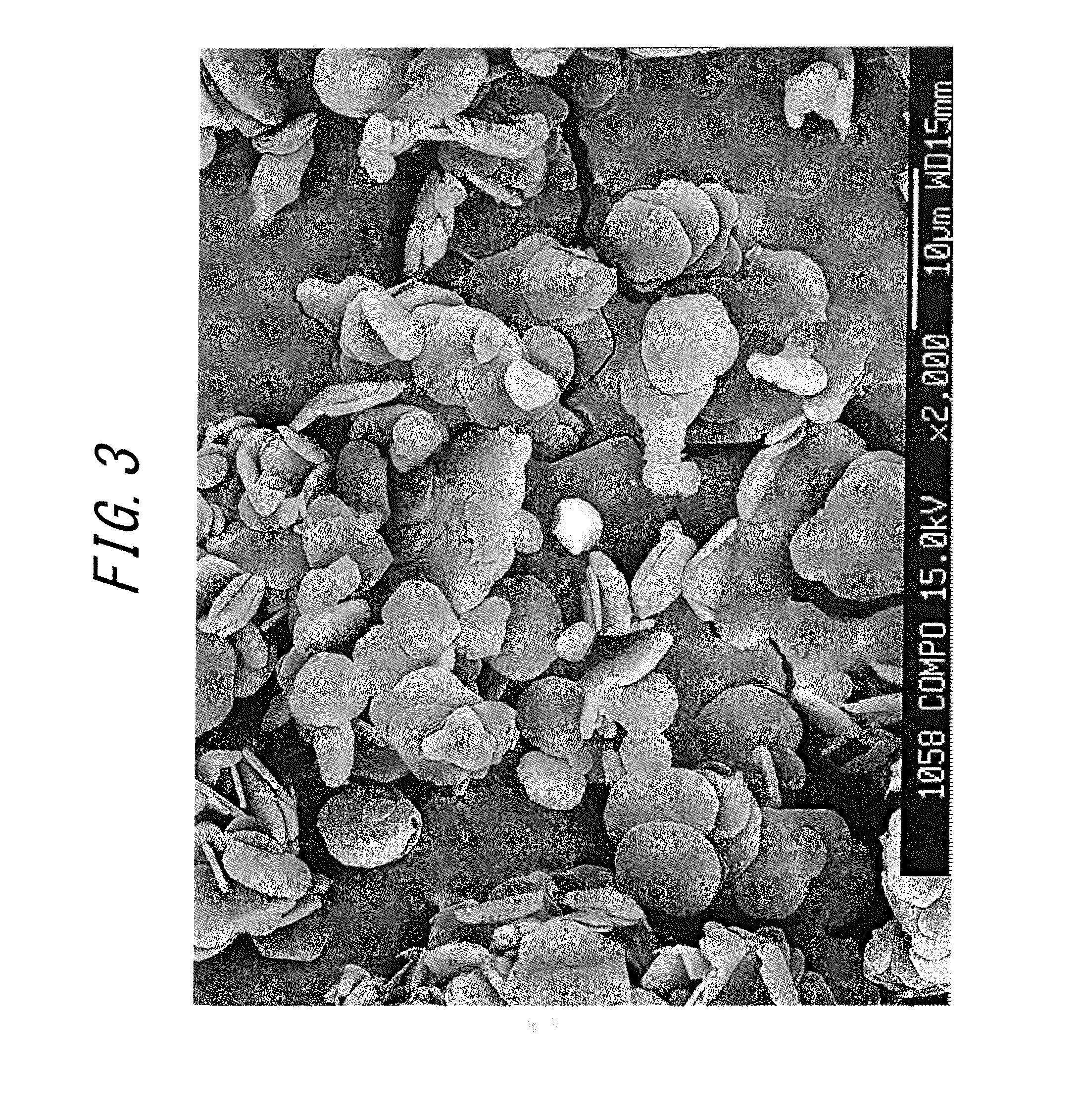

Hexagonal boron nitride powder having specific bulk density and residual Fe particles, and method for producing same

ActiveUS8679429B2Made denserHigh strengthNitrogen-metal/silicon/boron binary compoundsSynthetic resin layered productsLongest DiameterHexagonal boron nitride

A hexagonal boron nitride (h-BN) powder is disclosed in which primary particles of the powder exhibit a ratio (D / d) of long diameter (D) to thickness (d) in a range of 5 to 10. Agglomerated particle bodies made of the primary particles have an average particle diameter (D50) in a range of 2 μm to 200 μm, inclusive, and the powder has a bulk density in a range of 0.5 g / cm3 to 1.0 g / cm3. In an exemplary method for producing the h-BN, boron carbide is nitridizated in a nitrogen partial pressure of at least 5 kPa at 1800° C. to 2200° C., inclusive. B2O3 (or precursor thereof) is added to the nitridization product to produce a mixture. The mixture is decarbonized in a non-oxidizing atmosphere at a 1500° C. to 2200° C., inclusive. The decarbonization product is pulverized and subject to particle-size classification, yielding H-BN powder. The method includes a depressurizing step, performed at 100 kPa or less either during nitridization or after decarbonization.

Owner:MIZUSHIMA FERROALLOY

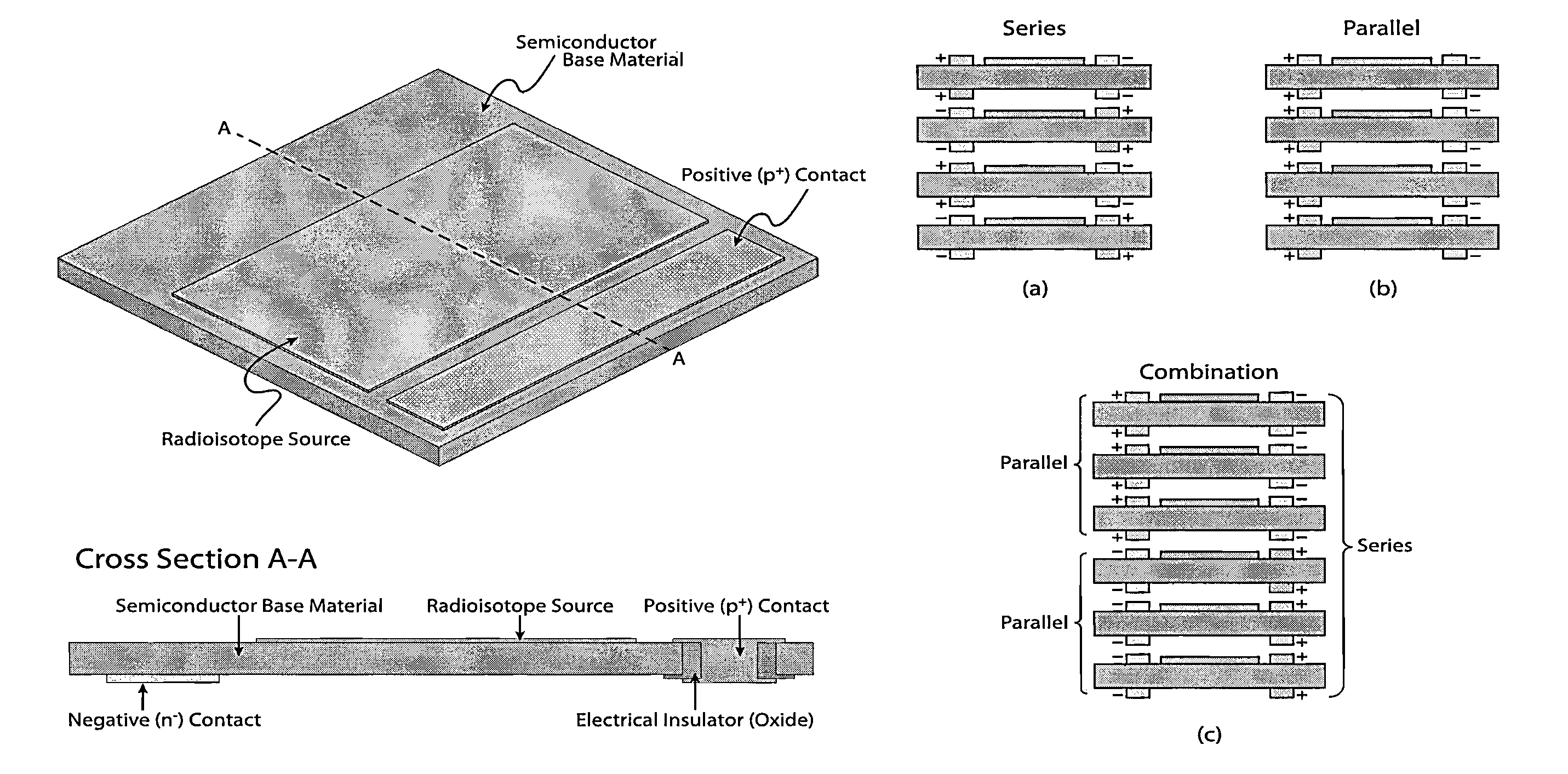

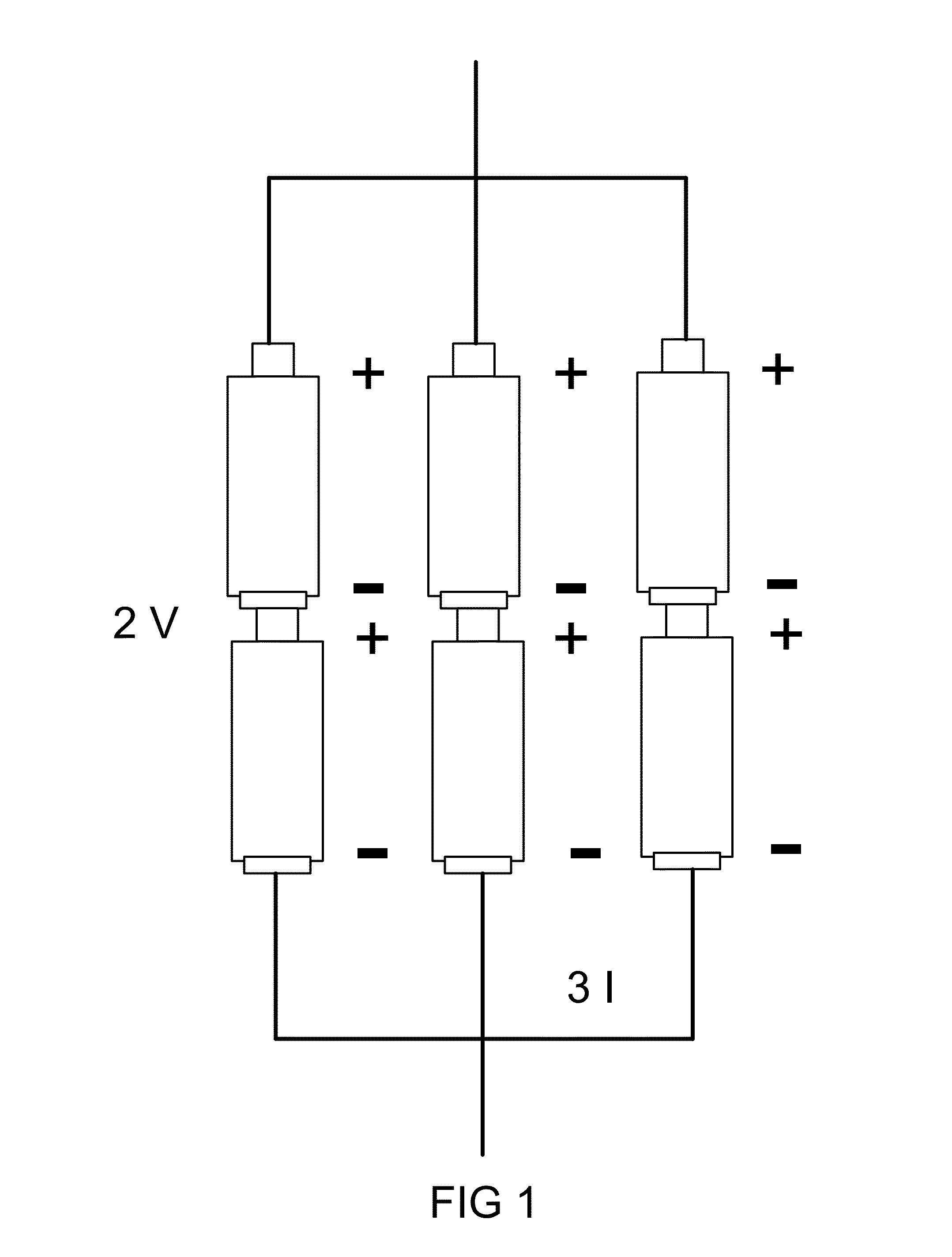

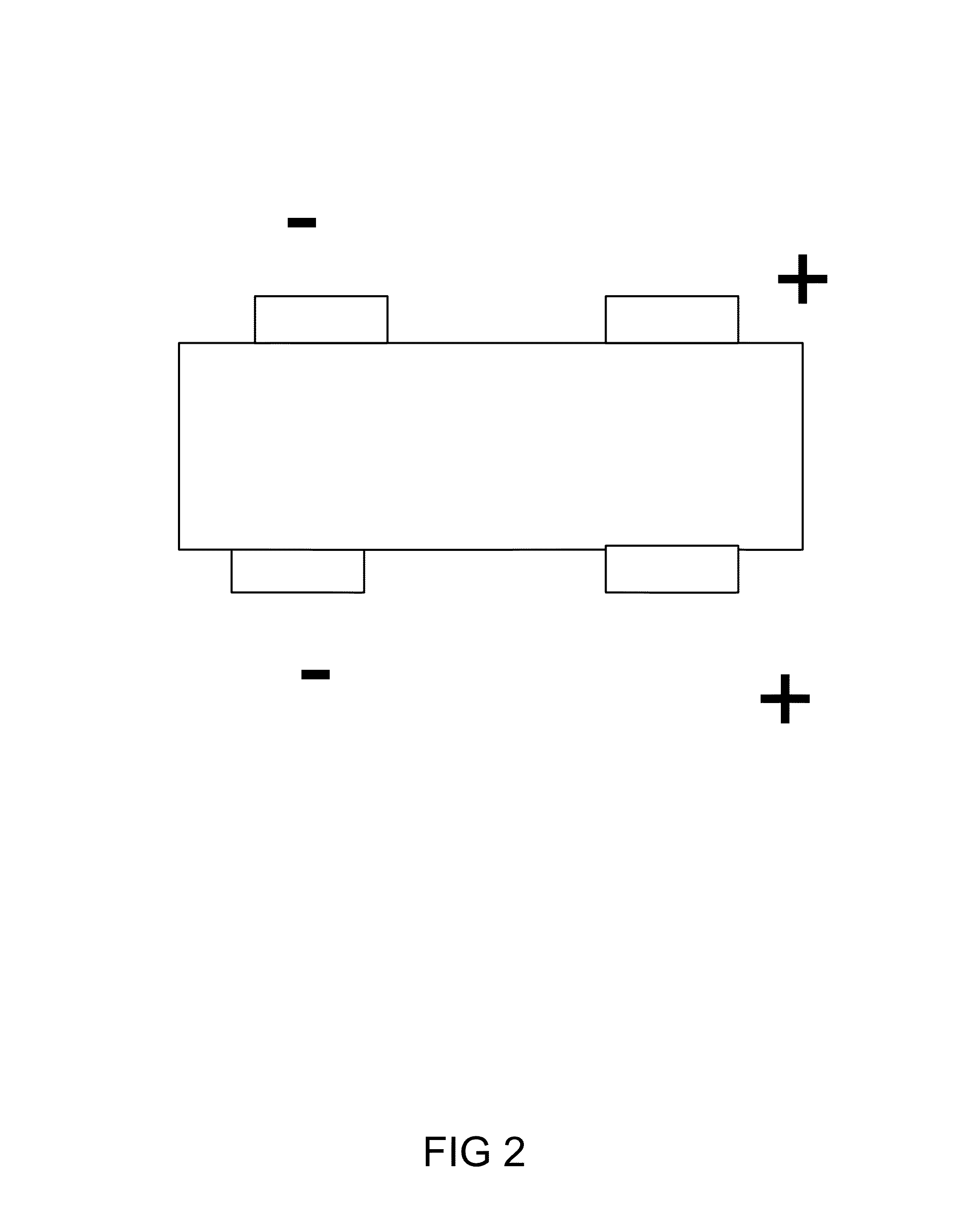

Low volumetric density betavoltaic power device

One example is a betavoltaic cell that has been fabricated using a semiconductor that includes, but is not limited to, Silicon Carbide (SiC), Silicon (Si), Gallium Arsenide (GaAs), Indium Gallium Arsenide (InGaAs), Gallium Nitide (GaN), Gallium Phosphide (GaP), or Diamond, and uses through wafer via holes or other fabrication techniques to form both positive (+ve) and negative (−ve) contacts on the front and back sides of the cell. In another example, several of these cells with +ve and −ve contacts on the front and back sides of the cell are arranged vertically and / or horizontally to form customized parallel and / or series combinations that produce a close packed, energy dense betavoltaic composite unit, with increased power outputs relative to a single cell. In another example, tritium or a metal tritide is used as the radioisotope source for the cells.

Owner:WIDETRONIX

High-thermoresistance forsterite light material and preparation thereof

The invention relates to a high-thermal resistance forsterite light material and a preparation method thereof. The technical scheme thereof is as follows: 20 to 60wt percent of chlorate powder and 40 to 80wt percent of forsterite crude ore powder are mixed at first; then a bonding agent accounting for 3 to 10wt percent of the mixture is added, stirred for 5 to 25 minutes, then pressed and shaped; and then the mixture is dried for 12 to 36 hours under the temperature condition of 60 to 110 DEG C or naturally dried for 24 to 48 hours indoors, sintered for 2 to 6 hours at the temperature between 800 and 1400 DEG C, cooled naturally, and soaked by water for 24 to 48 hours, then dried for 12 to 36 hours under the temperature condition of 60 to 110 DEG C or naturally dried for 24 to 48 hours indoors, finally the high-thermal resistance forsterite light material is prepared. The invention is characterized by abundant material resource, low production cost and easy industrial production. The volumetric density of the high-thermal resistance forsterite light material prepared by the method is between 0.8 and 2.0g / cm, with excellent performance as well as long service life; and the invention is applicable for various industrial thermal equipment below the temperature of 1300 DEG C.

Owner:WUHAN UNIV OF SCI & TECH

Method for controlling bulk density of carbon nanotube agglomerate

ActiveUS9809458B2Good mixing and dispersingHigh yieldCatalyst activation/preparationCarbon nanotubesCarbon nanotubeVolumetric density

The present invention relates to a method for producing a carbon nanotube aggregate whose bulk density is easily controllable. Therefore, the present invention provides a carbon nanotube aggregate suitable for use in various fields.

Owner:LG CHEM LTD

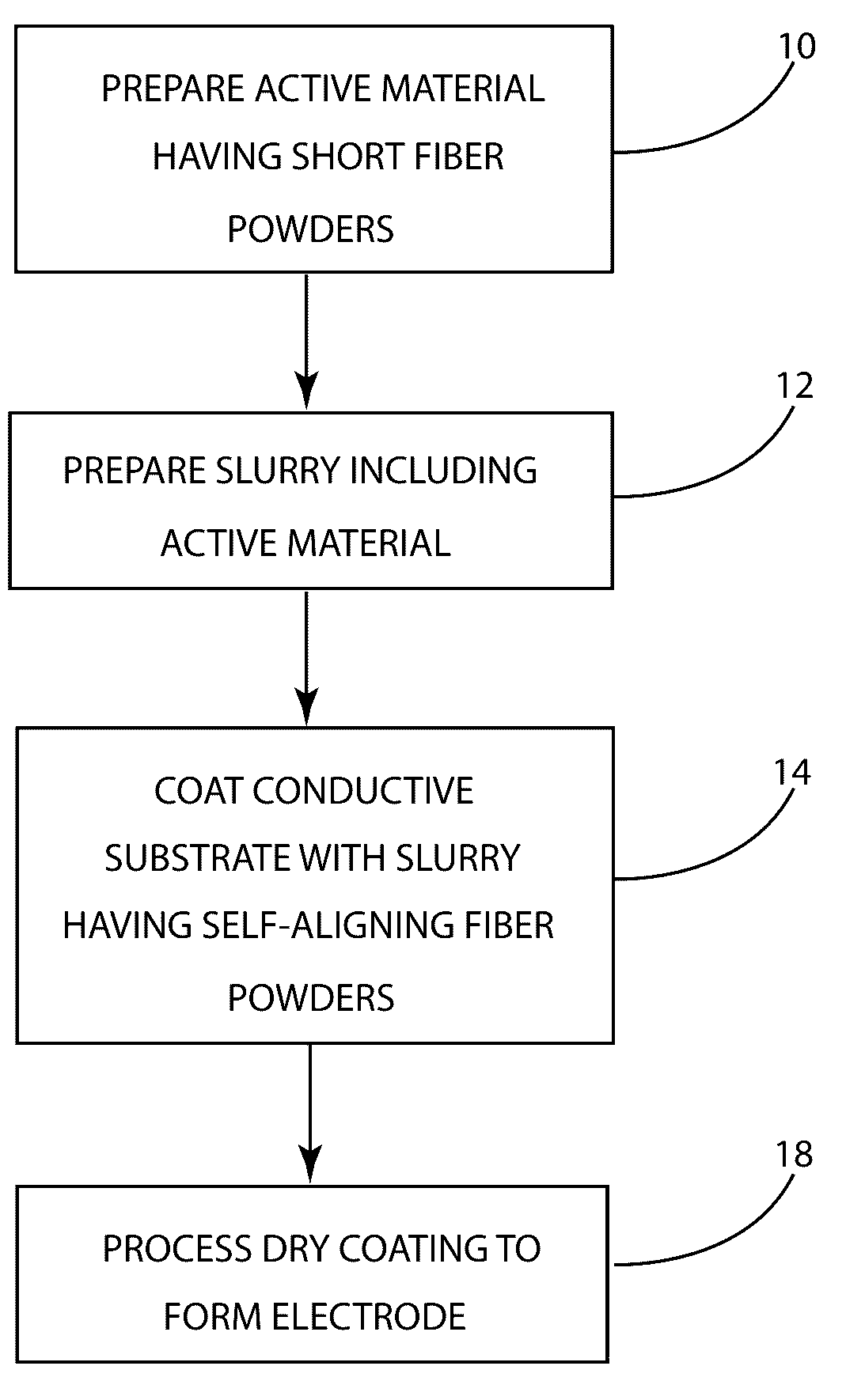

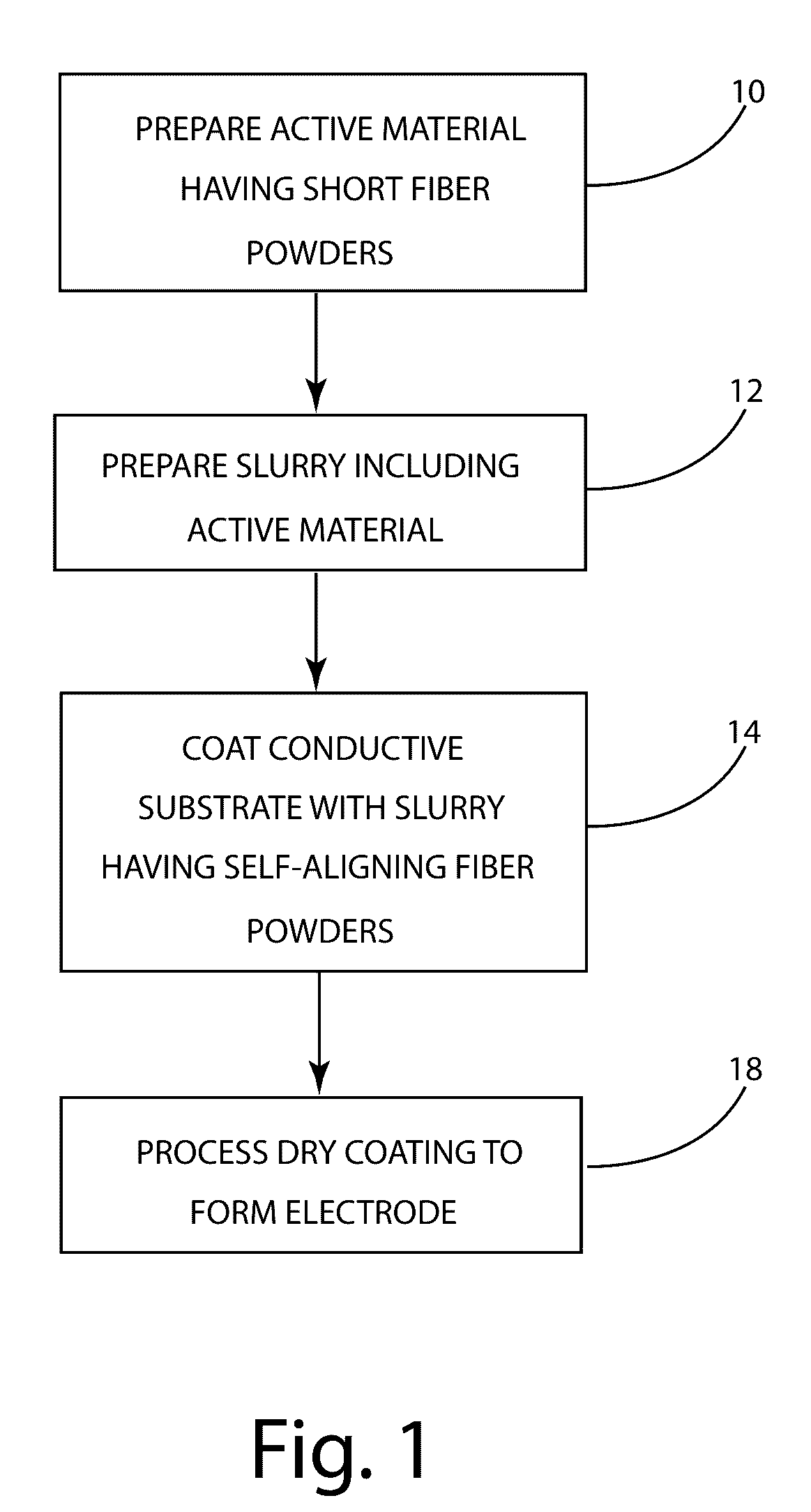

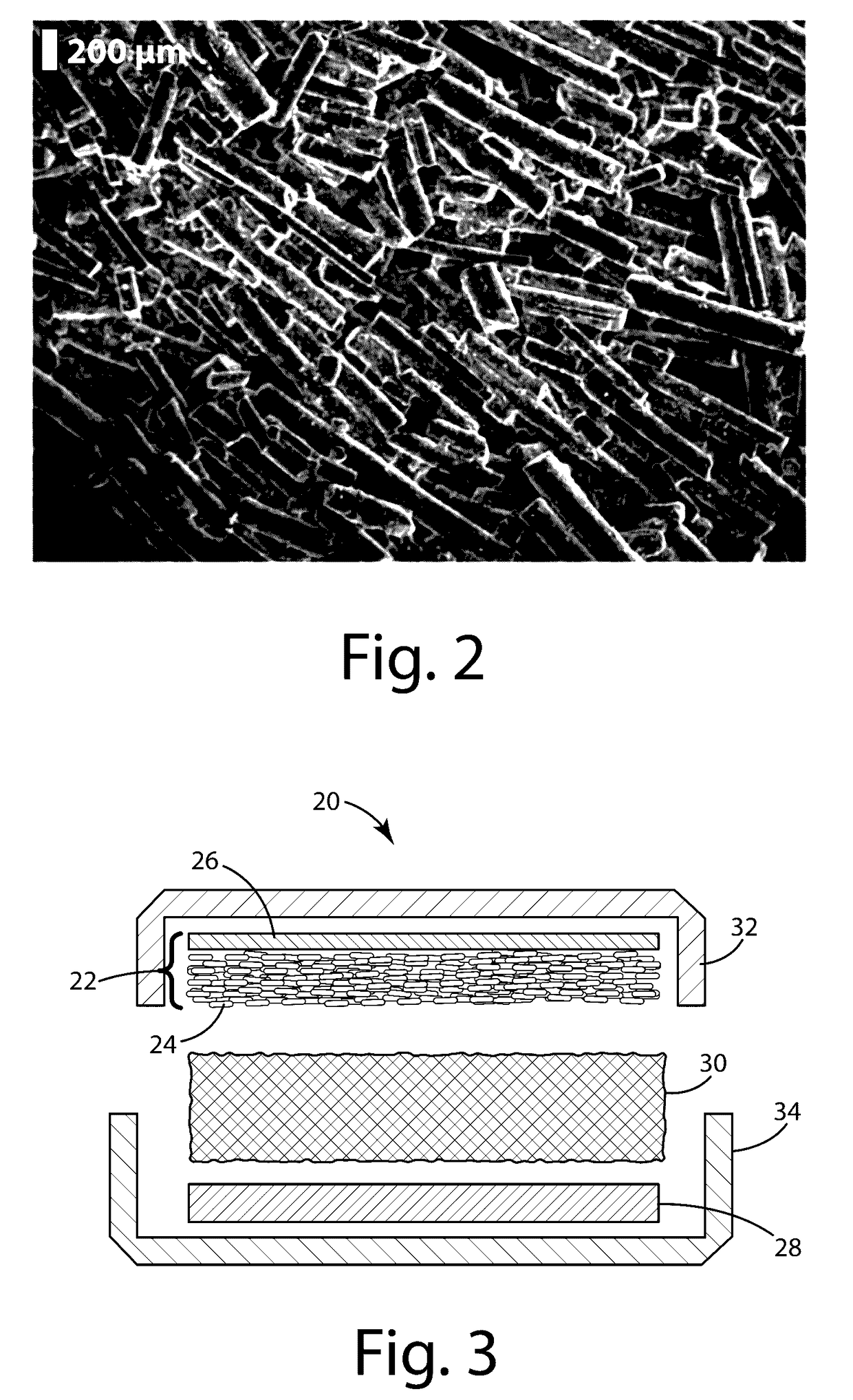

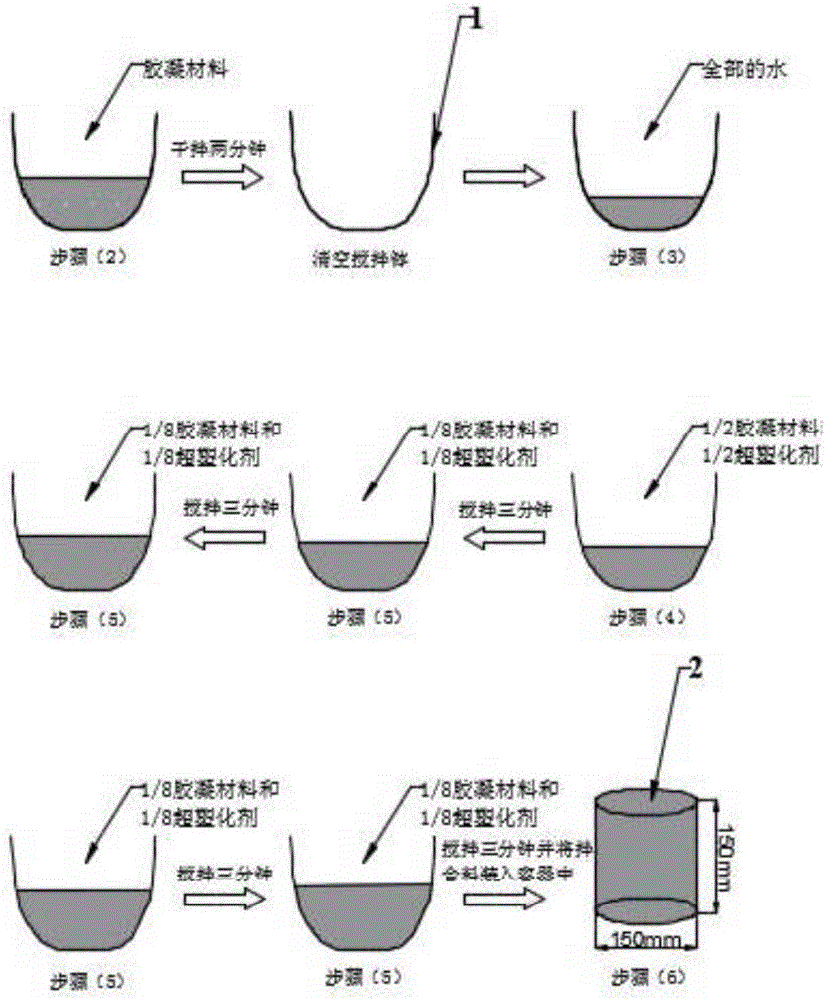

Method of manufacturing high volumetric density electrodes from self-aligning fiber powders

ActiveUS20170170453A1Increase capacityHigh bulk densityElectrode rolling/calenderingHybrid capacitor electrodesFiberVolumetric density

An electrode and a related method of manufacture are provided. The electrode includes a self-aligning active material having short fiber powders with a cylindrical morphology to increase the packing density from 0.74 to nearly 0.91. The short fiber powders self-align during a slurring coating process as a result of shear forces between a die and a foil. The resulting coating includes parallel short fibers in a closed packed arrangement, providing an increased volumetric capacity of at least approximately 17%.

Owner:UT BATTELLE LLC

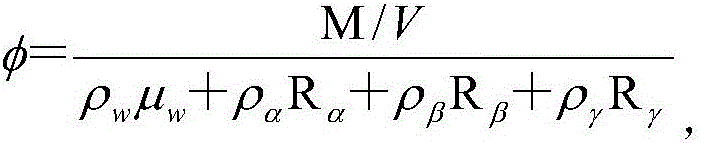

Method for determining bulk density and void ratio of wet bulk solid

The invention discloses a method for determining the bulk density and the void ratio of a wet bulk solid. The method comprises the steps of preparing raw materials required for an experiment according to a selected W / CM value, putting a cementing material into a mixing bowl for dry mixing, putting the mixed cementing material back to an original container and feeding all water required for the experiment in an empty pot body; feeding the mixed cementing material into the mixing bowl for mixing by five times, putting the mixed mixture into a cylindrical container to measure the bulk density of the mixture; and finally calculating the bulk density and the void ratio of the wet bulk solid according to experimental data and derived formula. By adopting a wet stacking method, the problems that a traditional method for testing the bulk density of a dry bulk solid is easily affected by a compacting factor and the influence which can be caused by a liquid to a sample are solved. Compared with the prior art, the method disclosed by the invention has the advantages that the bulk density and the void ratio of the wet bulk solid can be simply, quickly and accurately determined and the method can be applied to optimal proportion section of the wet bulk solid.

Owner:HENAN POLYTECHNIC UNIV

Forced closing method for improving multi-layer fracturing crack support profile

InactiveCN109958423ALarge particle sizeComprehensive optimization of shut-in time after fracturingFluid removalVolumetric densityEngineering

The invention discloses a forced closing method for improving a multi-layer fracturing crack support profile. The forced closing method includes the steps that (1) critical reservoir parameters are evaluated; (2) a layered crack propagation law is simulated; (3) an ultra-low density proppant is selected; the mean grain size of the proppant is 1 / 10 to 1 / 6 of the minimum crack width; and the bulk density of the proppant is less than 1.4g / cm<3>; and (4) the shut-in time after pressure is simulated, specifically, according to the fracturing construction parameters of adjacent wells around a well,different shut-in time after pressure is set, the change of the concentration profile of the proppant in different time is observed, and if the concentration profiles of the proppant in two certain shut-in time are very close, the previous time is taken as the final shut-in time. The forced closing method comprehensively optimizes the grain size of the proppant, the shut-in time after pressure andthe like, improves the multi-layer fracturing crack support profile, overcomes the current technical limitations, and maximizes the post-pressure yield-increasing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Beta-spodumene-cordierite composition, article, and method

Porous spodumene-cordierite honeycomb bodies of high strength but low volumetric density, useful for the manufacture of close-coupled engine exhaust converters, gasoline engine particulate exhaust filters, and NOx integrated engine exhaust filters, are provided through the reactive sintering of batches comprising sources of magnesia, alumina and silica together with a lithia source, such as a spodumene or petalite ore.

Owner:CORNING INC

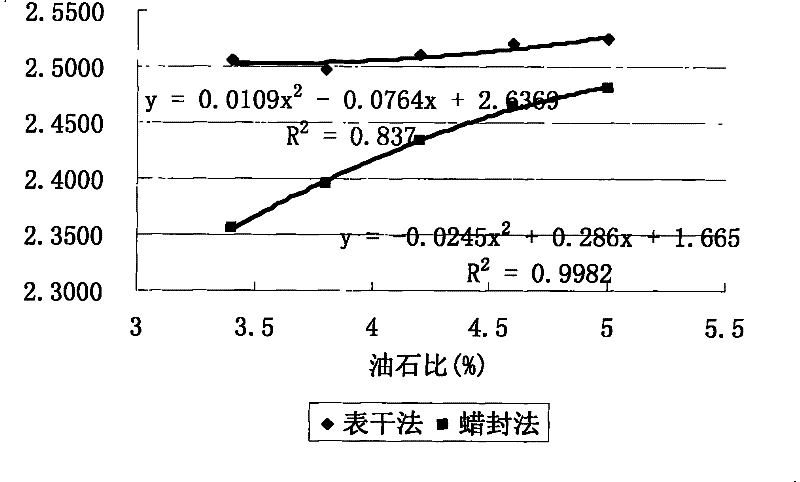

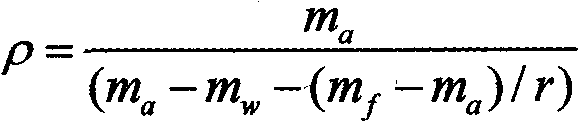

A New Wax Seal Method for Measuring Bulk Density of Asphalt Mixture

ActiveCN101477012BGuaranteed accuracyUniform densityPreparing sample for investigationMaterial weighingPresent methodVolumetric density

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

A kind of ultra-low density ceramsite proppant and preparation method thereof

InactiveCN106967408BReduce aluminum contentHigh outputFluid removalDrilling compositionAluminum fluorideKaolinite

Owner:TAIYUAN UNIV OF TECH

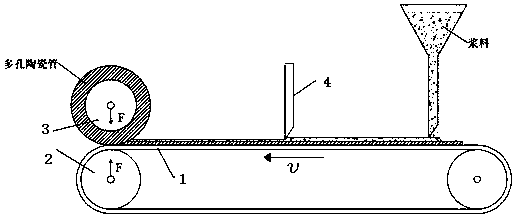

A kind of winding preparation method of high porosity porous ceramic tube

ActiveCN106565258BImprove mechanical propertiesHigh porositySurface layering apparatusCeramicwareFiberMetallurgy

The invention relates to a winding preparation method of a high-porosity porous ceramic pipe. The winding preparation method comprises: adding aluminum silicate polycrystalline fiber, a binder and the like into water to prepare a slurry, and preparing a paper-like fiber film having fibers extending in a two-dimensional direction by using a papermaking molding method; uniformly coating the slurry prepared from the chopped aluminum silicate polycrystalline fiber, the aluminum silicate ceramic fine powder and the binder on the surface of the fiber film; winding under a certain external force to form a pipe billet having a predetermined size and a predetermined bulk density; and finally carrying out low temperature drying and high temperature firing to prepare the porous ceramic pipe. According to the present invention, the porous ceramic pipe has high porosity, and has low filtration pressure drop during solid-liquid separation or solid-gas separation; and the ordered arrangement of the fibers and the granular crystal is achieved by using the multi-layer winding method, and the fibers and the crystal are connected to form the grid structure through the firing, such that the material has the high porosity and the low filtration pressure drop, and further has good mechanical property and good economy.

Owner:江苏省陶瓷研究所有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com