Method for determining bulk density and void ratio of wet bulk solid

A technology of bulk density and measurement method, applied in the field of mine tailings filling, can solve the problems of not considering the possible influence of water, sensitive defects of compaction factors, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

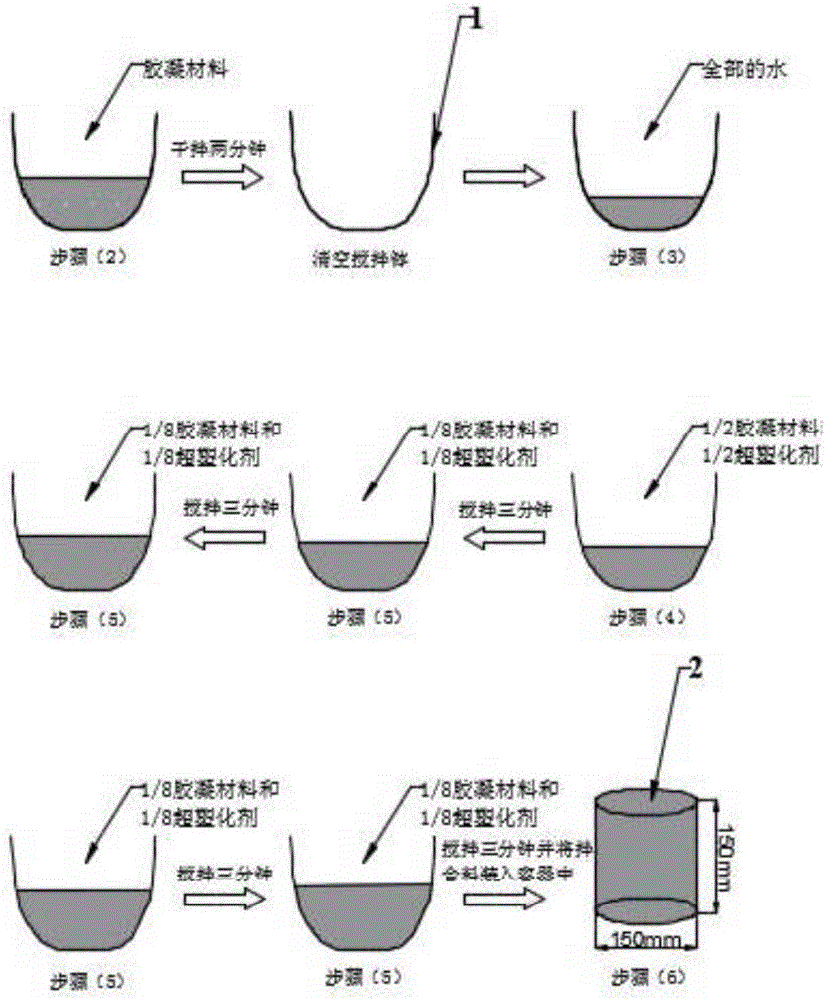

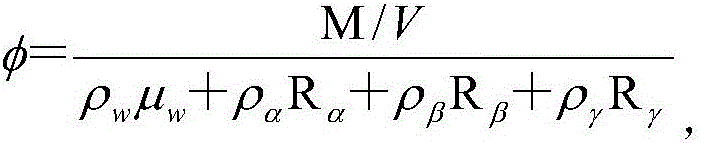

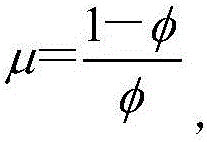

[0027] A method for measuring bulk density and void ratio of wet bulk is realized through the following steps:

[0028] (S1) According to the selected wet dispersion W / CM value, where W represents water and CM represents cementitious material, prepare water, ordinary Portland cement and fly ash of required weight, and place them in separate In the container, spare;

[0029] (S2) Add ordinary portland cement into the mixing bowl and dry mix for two minutes to improve the uniformity of the cementitious material sample;

[0030] (S3) Put the ordinary Portland cement stirred in the mixing bowl 1 into the original container, and add all the water of the required weight into the empty mixing bowl 1;

[0031] (S4) Add half of the ordinary Portland cement and half of the fly ash into the mixing bowl filled with water, start the stirrer and stir for three minutes at low speed;

[0032] (S5) Divide the remaining ordinary portland cement and fly ash into four equal parts and add them t...

Embodiment 2

[0042] A method for measuring bulk density and void ratio of wet bulk is realized through the following steps:

[0043] (S1) According to the selected wet dispersion W / CM value, where W represents water and CM represents cementitious material, prepare the required weight of water, ordinary Portland cement and silica fume, and put them in separate containers inside, spare;

[0044] (S2) Add ordinary Portland cement into the mixing bowl 1 and dry mix for two minutes to improve the uniformity of the cementitious material sample;

[0045] (S3) Put the ordinary Portland cement stirred in the mixing bowl 1 into the original container, and add all the water of the required weight into the empty mixing bowl 1;

[0046] (S4) Add half of the ordinary Portland cement and half of the silica fume into the mixing bowl filled with water, start the stirrer and stir at a low speed for three minutes;

[0047] (S5) Divide the remaining ordinary portland cement and silica fume into four equal p...

Embodiment 3

[0057] A method for measuring bulk density and void ratio of wet bulk is realized through the following steps:

[0058] (S1) According to the selected wet dispersion W / CM value, where W represents water and CM represents cementitious material, prepare water, ordinary Portland cement, fly ash and silica fume of required weight, and place them respectively In a separate container, set aside;

[0059] (S2) Add ordinary Portland cement into the mixing bowl 1 and dry mix for two minutes to improve the uniformity of the cementitious material sample;

[0060] (S3) Put the ordinary Portland cement stirred in the mixing bowl 1 into the original container, and add all the water of the required weight into the empty mixing bowl 1;

[0061] (S4) Add half of ordinary Portland cement, half of fly ash and half of silica fume into a mixing bowl filled with water, start the stirrer and stir for three minutes at a low speed;

[0062] (S5) Divide the remaining ordinary Portland cement, fly ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com