Electronic measuring equipment and method for ceramic volumetric density

A bulk density and electronic measurement technology, which is applied in the direction of material analysis by measuring buoyancy, electrical digital data processing, special data processing applications, etc., can solve the problems of heavy workload, increase the source of error, and affect the accuracy of bulk density. Achieve the effect of high accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

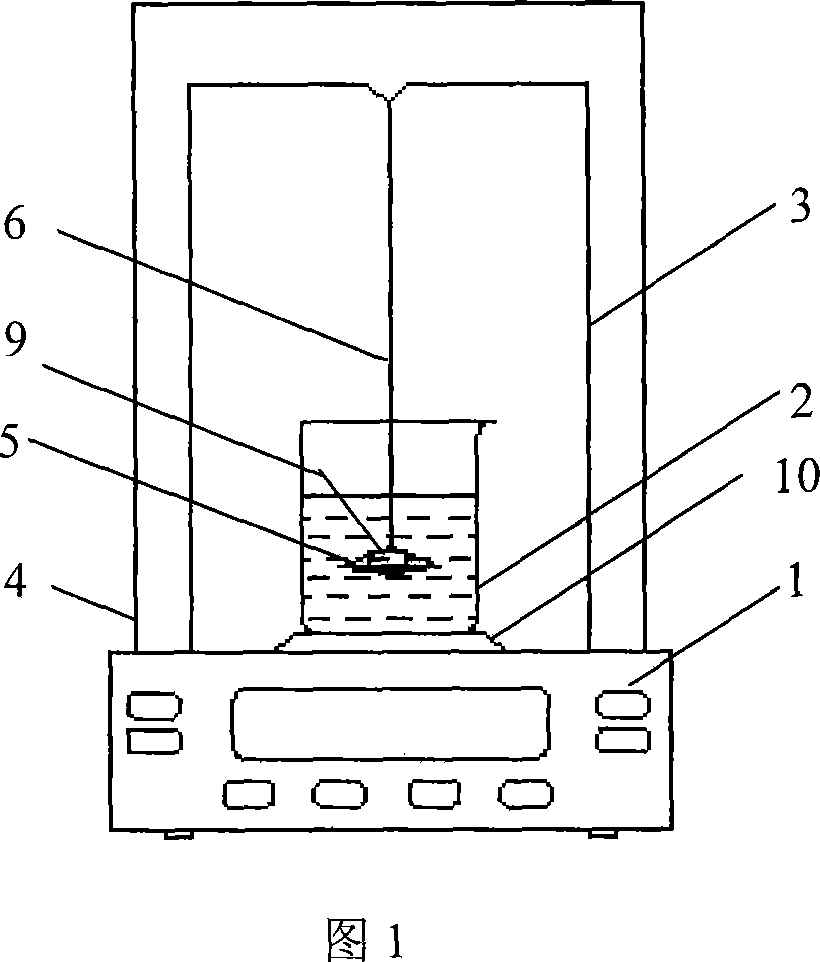

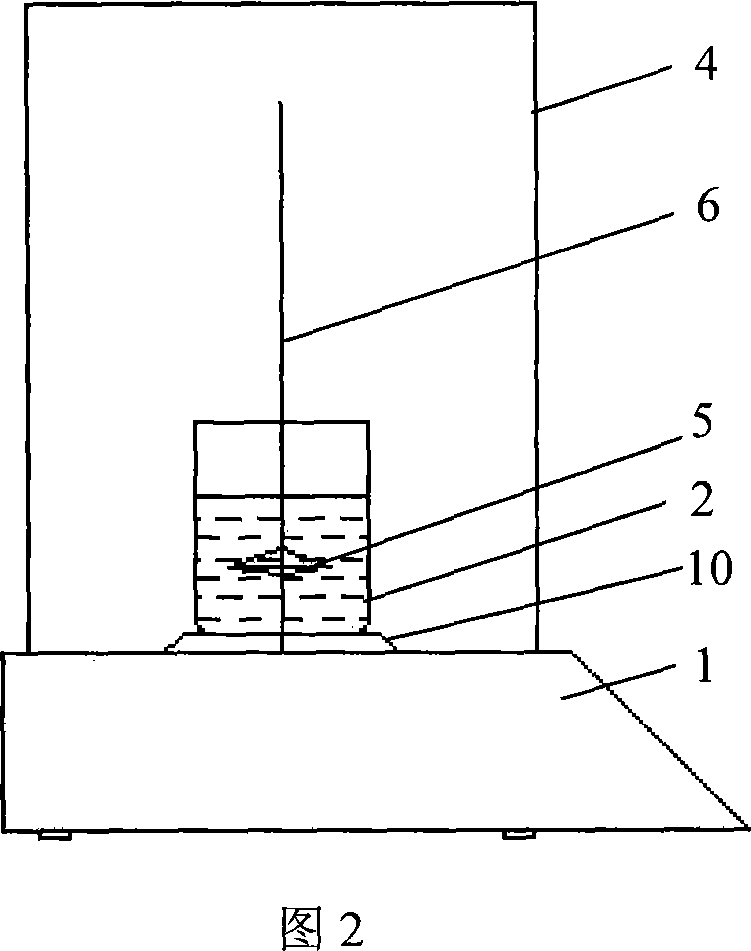

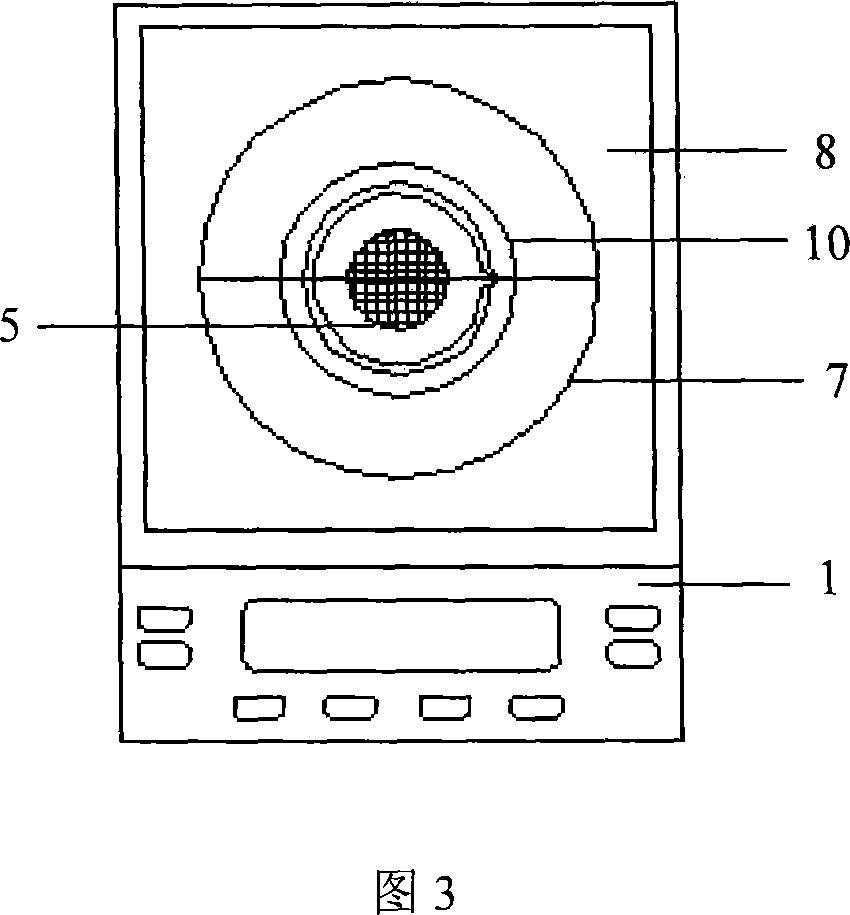

[0017] In Fig. 1, the water cup 2 is placed on the weighing pan 10 of the electronic balance 1, the hanging basket 5 is connected to the support 3 by a thin copper wire 6, the hanging basket 5 is immersed in the water in the water cup 2, and the support base 7 Distribute the load evenly on the electronic balance bearing platform 8. The total mass of the water cup and water should be less than the range of the electronic balance. When the system is in a balanced state, reset the balance to zero, and gently put the wet ceramic piece 9 with the surface wiped off moisture into the hanging basket 5. At this time, the value displayed on the balance is m, and the volume density of the ceramic piece can be calculated ρ = m 0 × ρ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com