Beta-spodumene-cordierite composition, article, and method

A technology of spodumene and cordierite, applied in the field of β-spodumene-cordierite composition, product and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

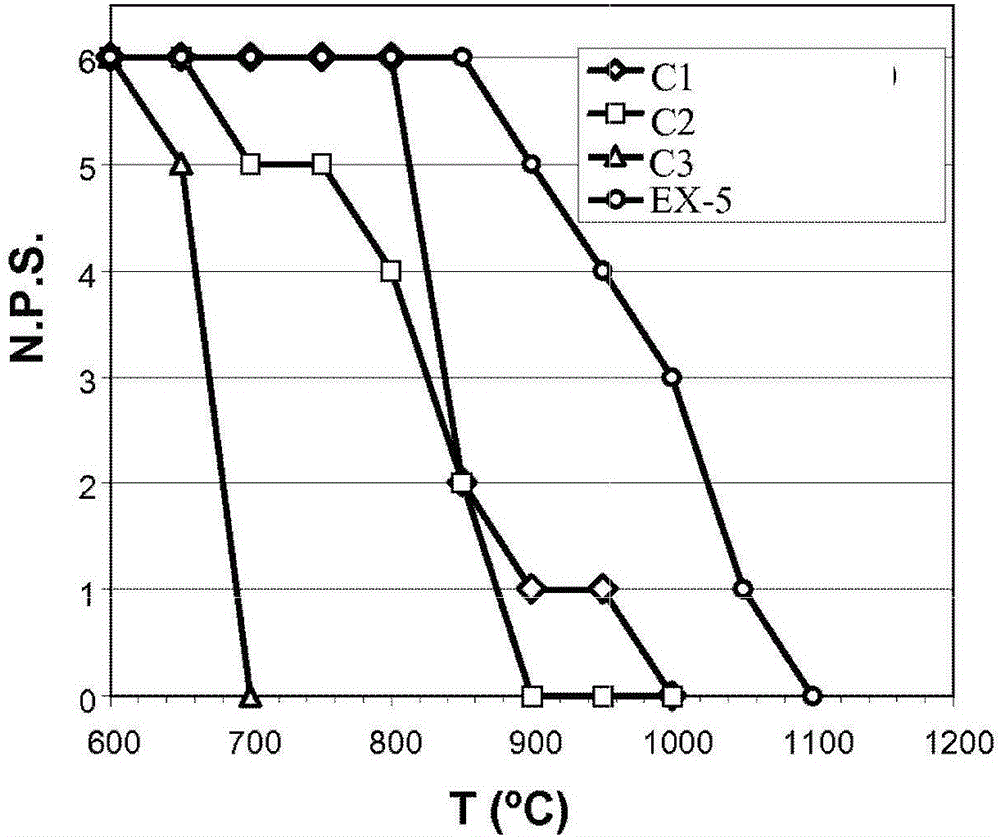

[0033] Example A - Ceramic Composition

[0034] Tables 1 and 2 below give the batch composition and physical properties of some spodumene-cordierite composites. For comparison, examples of cordierite materials are also reported, including commercially available cordierite (composition C1 ), non-microcracked cordierite containing lanthanum glass (composition 2 ) and non-microcracked cordierite (composition C3) made primarily from mineral batches seeded with cordierite crystals to limit the domain size. Composite compositions prepared according to the invention in Tables 1 and 2 were compounded using the α-spodumene mineral as the lithium source, which mineral contained 6% by weight of Li 2 O, 25.3 wt% Al 2 o 3 and 64.6 wt% SiO 2 , the balance including traces (each less than 1% by weight) of Fe 2 o 3 、Na 2 O, K 2 O.P 2 o 5 and MnO 2 .

[0035] The batch compositions in Table 1 are expressed in parts by weight. For each batch composition reported, Table 1 contains t...

Embodiment B

[0043] Example B - Catalyst Compatibility

[0044] Poisoning of the catalyst surface by the alkali component of the sintered ceramic is found to be a problem for the β-spodumene catalyst substrate. For three-way washcoat catalysts, two mechanisms have been found. The first mechanism arises from the fact that the pH of the washcoat slurry is usually below 4. Therefore, the protons from the acidic washcoat slurry can ion-exchange with the lithium from the spodumene, so some lithium ions can deposit on the catalyst sites, poisoning the catalyst activity. The origin of the second mechanism is that lithium can diffuse from spodumene to the catalyst at high temperature. The presence of steam in the combustion exhaust stream accelerates this process.

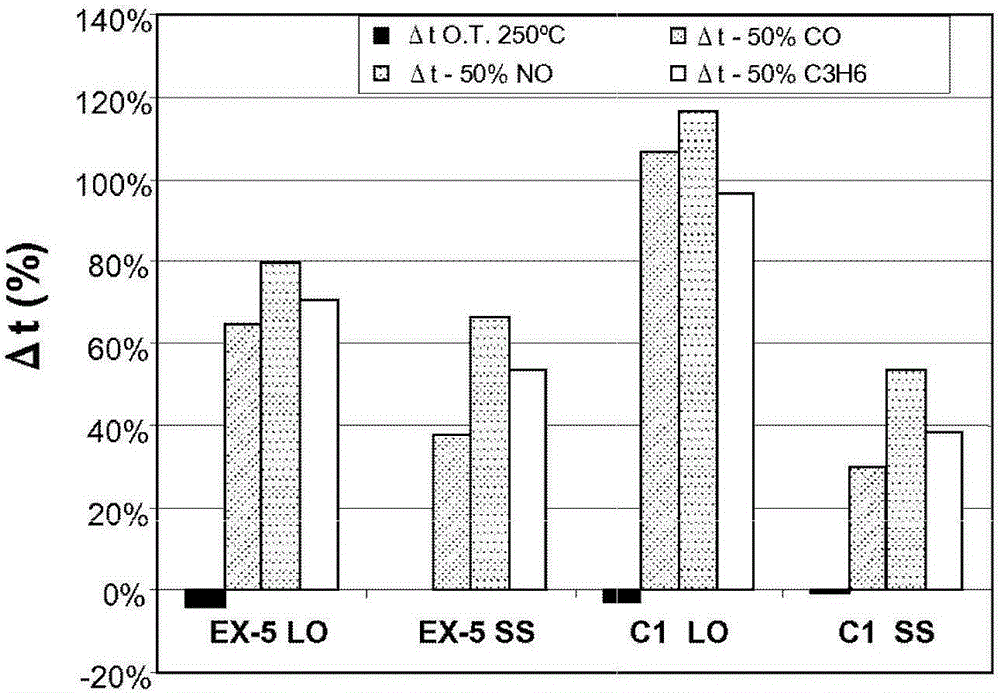

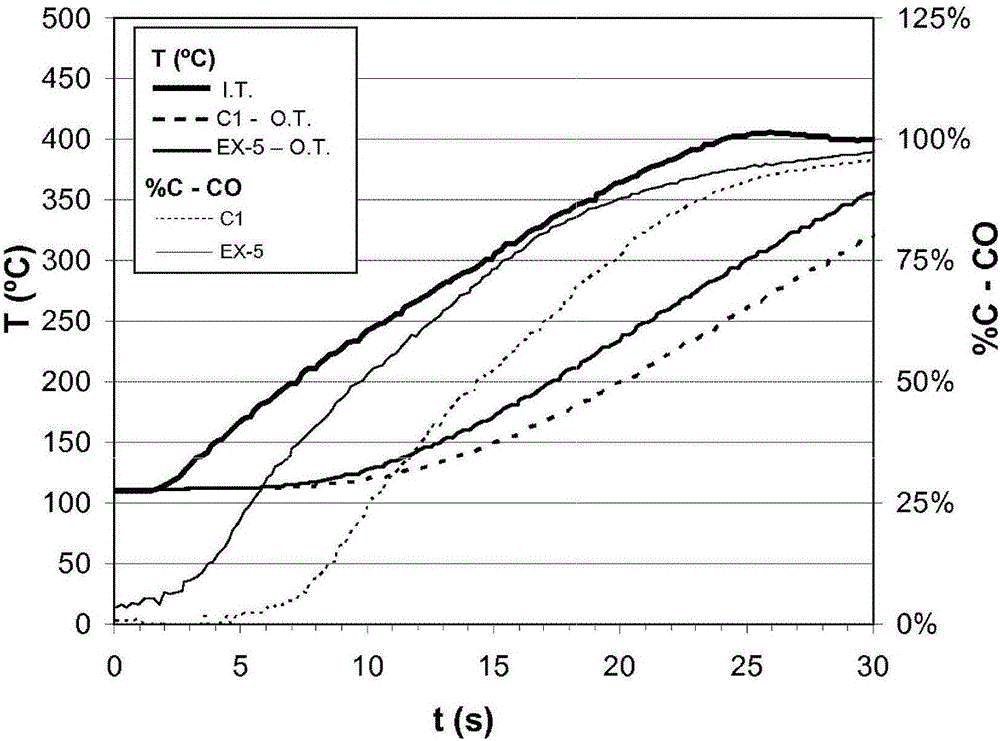

[0045] By comparing the catalytic conversion efficiencies of propylene, carbon monoxide, and nitrous oxide on the respective catalysts deposited on spodumene-cordierite composite honeycomb substrates and conventional cordierite hone...

Embodiment

[0061] Example C - Catalyst Substrate Stability

[0062] The effect of washcoating on the properties of the catalyst substrate can be significant, including changes from firing the initially applied washcoat as well as changes after extended operating thermal cycling times.

[0063] The data presented in Table 4 below compares the effects of washcoating and heat aging on the physical properties of cordierite and spodumene-cordierite composite honeycomb articles. Four honeycombs with different compositions were compared, including the EX-2 spodumene-cordierite composite composition in Tables 1 and 2, the cordierite compositions C2 and C3 reported in Tables 1 and 2, and a wide range of automotive exhaust systems Another commercially available cordierite honeycomb composition C4 was used.

[0064] Table 4 contains the following physical property values for each honeycomb sample tested: modulus of rupture (MOR) strength, modulus of elasticity (EMOD), strain tolerance (ST), aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com