Method for batch preparation of uniform density carbon/carbon composite flat by using limited domain reactor

A carbon composite material, a technology of uniform density, applied in the field of carbon/carbon composite materials, can solve the problems of large difference in bulk density between individuals, unfavorable product performance stability, poor densification uniformity, etc., so as to reduce thermal deformation and increase effective utilization. rate, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Uniform vapor phase densification method of carbon / carbon composite flat plate:

[0072] (1) The size specification is 350×350×30mm, the apparent density is 0.46g / cm 3 The carbon fiber integral needle-punched felt is placed in a high-temperature graphitization furnace, and the carbon fiber preform is heat-treated at 1800°C under an argon protective atmosphere and kept for 2 hours.

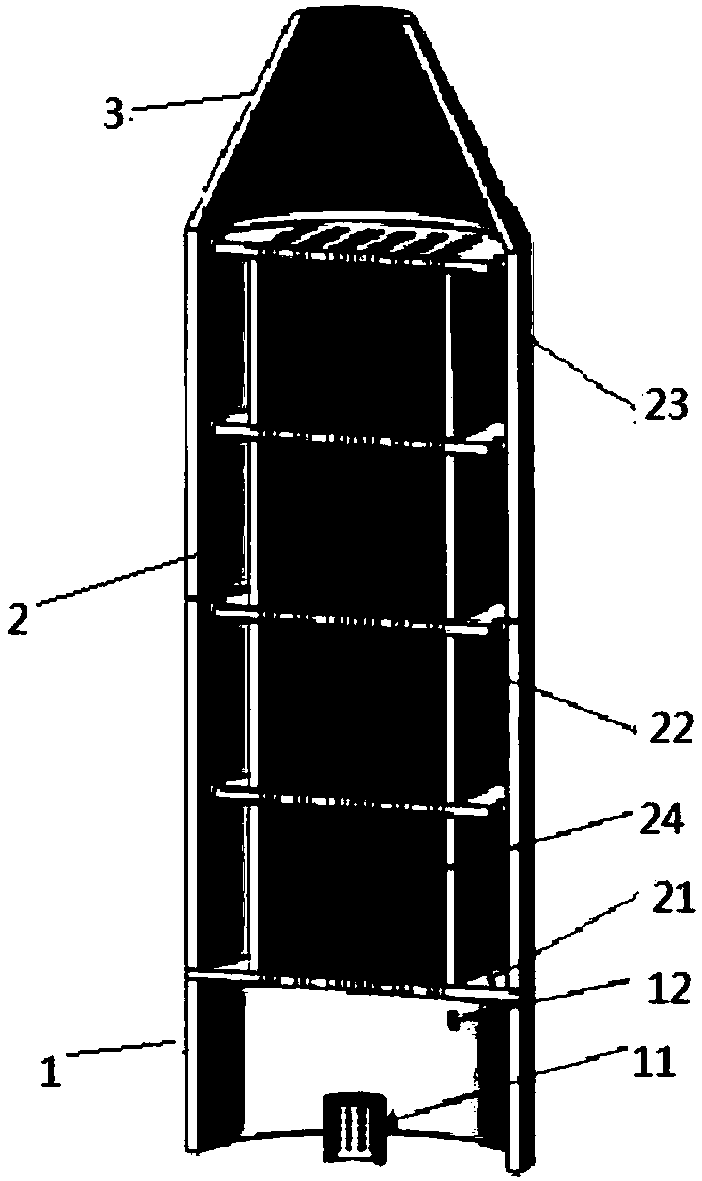

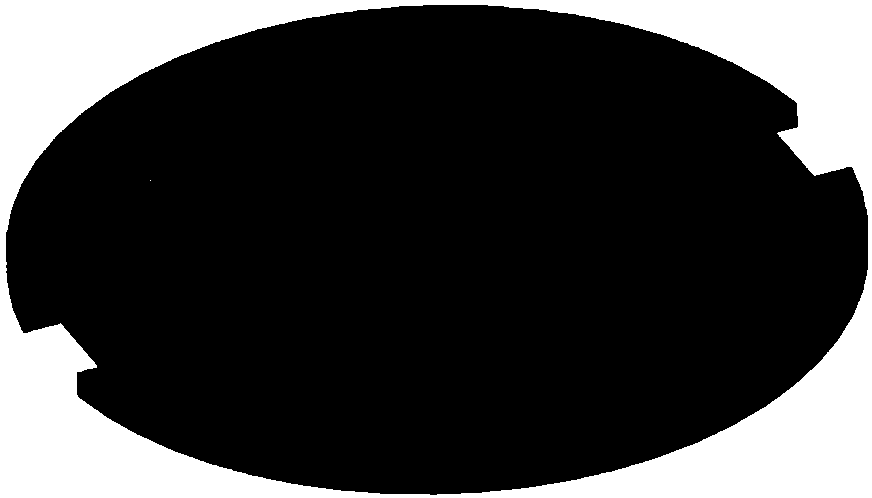

[0073] (2) According to the attached figure 1 To set up a confinement reactor, first place the gas distribution cap at the bottom center of the cylinder, then place the first gas distribution plate, and then directly load the first group of 4 carbon fiber flat plate preforms on the first distribution block in an upright form. Gas plate, and ensure that any piece of carbon fiber flat prefabricated body stands upright on the blank area of the first gas distribution plate; then install the second gas distribution plate above the first group of carbon fiber flat prefabricated bodies and fix i...

Embodiment 2

[0079] Uniform vapor phase densification method of carbon / carbon composite flat plate:

[0080] (1) Continue to load the carbon / carbon composite material plates obtained in Example 1 according to the order of L1, L2, L3, and L4, and at the same time, rotate the individual carbon / carbon composite material plates by 180° for loading.

[0081] (2) Using propylene as the carbon source gas, nitrogen as the dilution gas, wherein the flow rate of propylene is 35L / min, and the flow rate of nitrogen is 10L / min, and the chemical vapor deposition method is used for pyrolytic carbon densification, and the deposition temperature is 950°C. The deposition pressure is 0.7-0.8kPa, and the deposition time is 100h.

[0082] (3) Carry out surface machining on the carbon / carbon composite material flat plate, load according to the order of L4, L3, L2, L1, and rotate the individual carbon / carbon composite material flat plate by 180° for loading, the above step (2) under the deposition process condit...

Embodiment 3

[0089] Uniform vapor phase densification method of carbon / carbon composite flat plate:

[0090] (1) The size specification is 500×300×7mm, the apparent density is 0.98g / cm 3 The carbon cloth suture prefabricated body was placed in a high-temperature graphitization furnace, and the carbon fiber prefabricated body was heat-treated at 2000 °C under an argon protective atmosphere and kept for 2 hours.

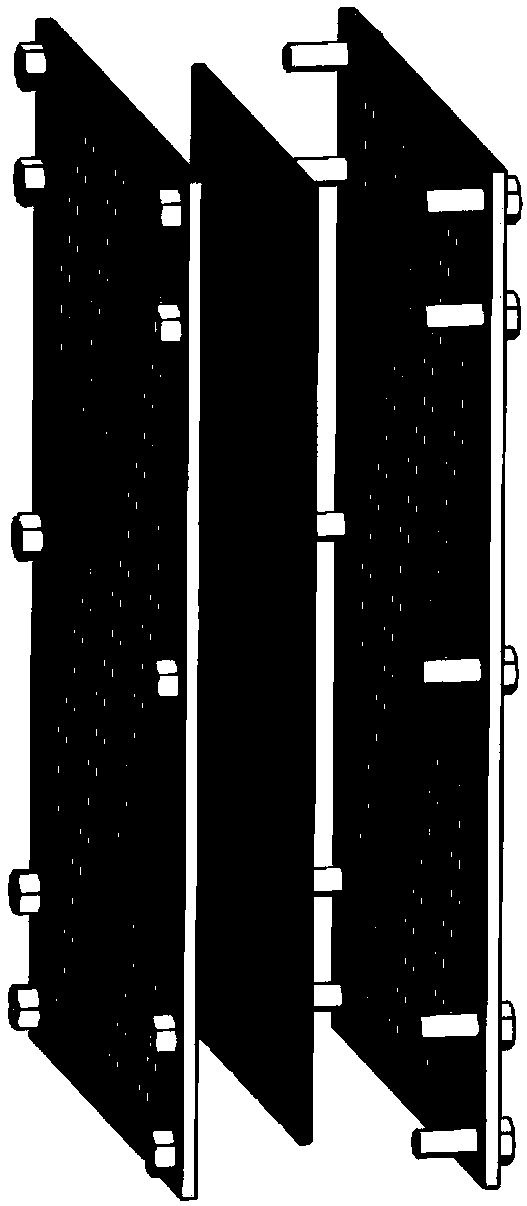

[0091] (2) According to the attached figure 1To set up the confinement reactor, first place the gas distribution cap at the bottom center of the cylinder, then place the first gas distribution plate, and then place the first group of 4 carbon fiber flat plate preforms in an upright form with two pieces of graphite anti-deformation tooling Clamp and load on the first gas distribution plate, and ensure that any piece of carbon fiber flat prefabricated body stands upright on the blank area of the first gas distribution plate; then install the second gas distribution plate on the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com