Ultra high power graphite resistor rod with 600mm diameter and method for producing the same

A graphite electrode and production method technology, applied in the direction of electric heating devices, electrical components, heating through discharge, etc., can solve the problems of high production costs and expensive imported raw materials, and achieve the effect of reducing production costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

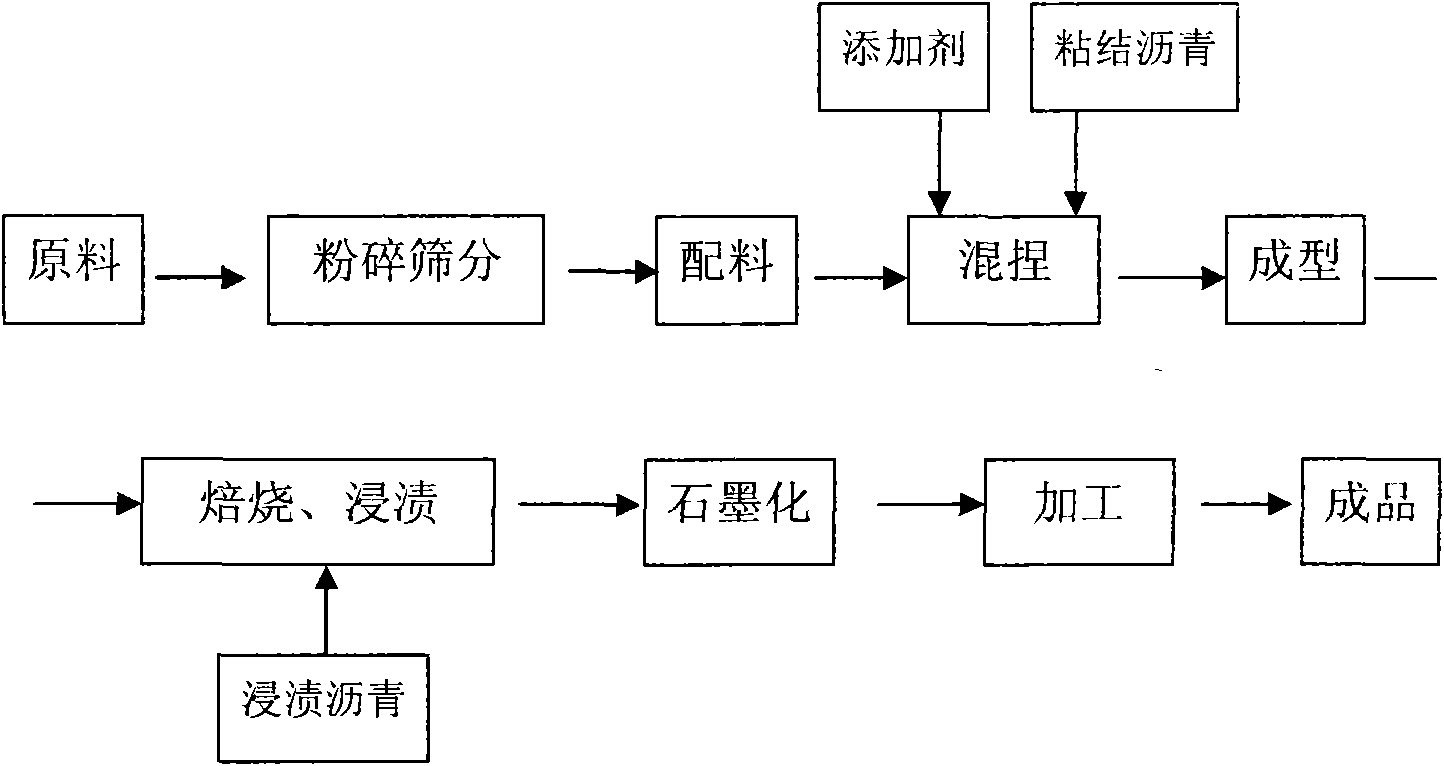

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation mode of the present invention will be described in detail below in conjunction with the examples.

[0024] The product of the present invention uses 100% coal-based needle coke produced in Shanxi Hongte as a raw material. According to the microstructure of the raw material, the properties of true density, thermal expansion coefficient, tap density, and crushing strength, and the impact of the coal-based needle coke on The adsorption performance of the binder is designed to formulate ultra-high power graphite electrodes with large, medium and small particle sizes. The formula includes 20-30mm large-sized coal-based needle coke, 10-20mm medium-sized coal-based needle coke, and small-sized powder less than 200 meshes, as well as binder-modified pitch, additive stearic acid and Fe 2 o 3 Iron powder, raw and broken components, the composition is calculated by weight percentage: 20-30mm large-sized coal-based needle coke 40%, 10-20mm medium-sized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com