Anti-blocking type large drum screen structure equipment

A trommel screen, large-scale technology, applied in the fields of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems of decreased screening capacity, unable to replace screen, easy accumulation of screen, etc., to improve service life and solve large-scale problems. The effect of production and selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

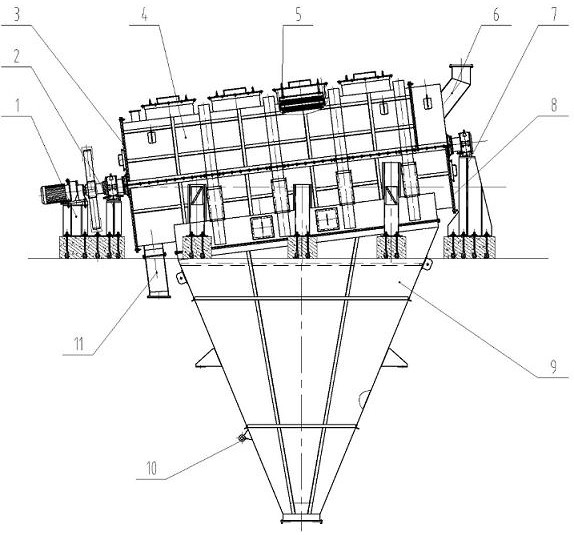

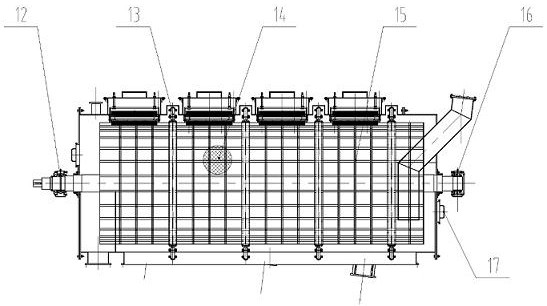

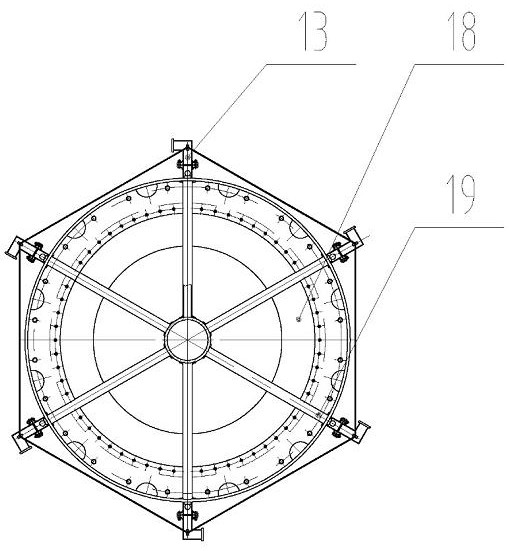

[0029] like Figures 1~7 As shown, an anti-blocking type large-scale trommel screen structure equipment includes a casing 4 with an upper and lower two-lobed structure and inclinedly arranged, a transmission shaft placed in the casing 4, and a transmission system 1 connected with the transmission shaft.

[0030] One end of the casing 4 is provided with a power end plate 3, the upper part of the other end is provided with a feed port assembly 6, and the lower part is provided with a feed end end plate 8; the power end end plate 3 is connected with a fixed end support frame 2, the The fixed end support frame 2 is connected with the transmission system 1 ; the feed end end plate 8 is connected with a free end support frame 7 . The top of the casing 4 is provided with a brush cleaning mechanism 5, and the bottom is provided with a lower hopper 9 and an upper sieve hopper 11 respectively; one side of the lower hopper 9 is provided with a hopper hammer 10; A screen body 15 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com