Apparatus for petrol engine combustion methanol cracking gas

A methanol cracking device and methanol cracking gas technology, which is applied in the field of methanol cracking gas burning gasoline engine, can solve the problem of difficult cold start of burning methanol, and achieve the effect of alleviating energy shortage, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

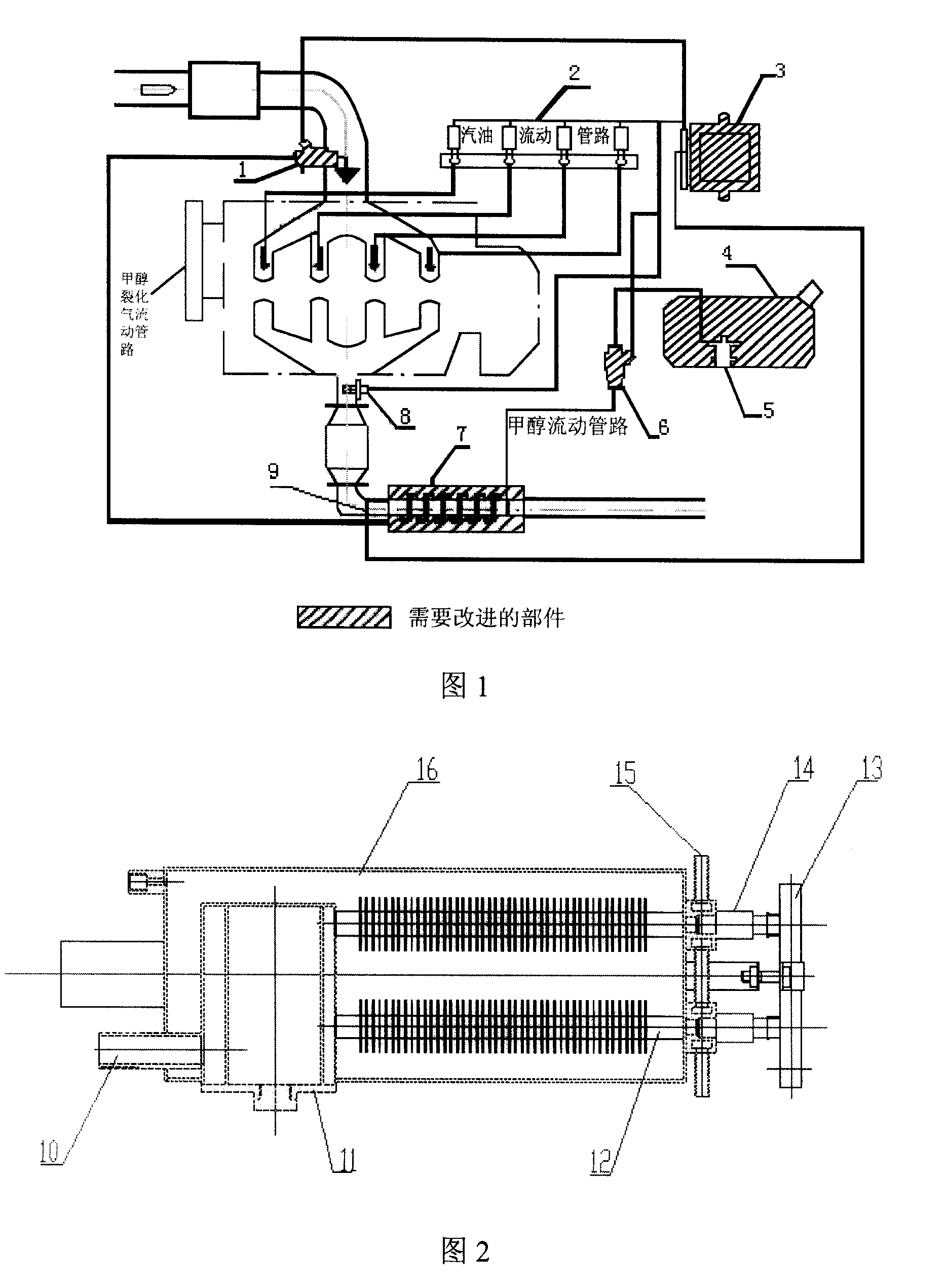

[0015] With reference to Fig. 1, Fig. 2, it can be seen that the device for gasoline engine burning methanol cracked gas of the present invention, in addition to comprising the existing gasoline engine gasoline injection control system, has also installed methanol cracked gas injection valve 1, methanol supply system, methanol The cracking device 7 and the fuel switching system heat the methanol cracking device 7 so that the methanol is cracked into carbon monoxide and hydrogen under the action of the catalyst for use by the engine.

[0016] Among them, the methanol supply system consists of a methanol tank 4, a methanol pump 5, and a methanol injection valve 6, and is mainly used for storage of methanol and supply to the cracking device 7.

[0017] The methanol cracking device 7 mainly includes components such as a chamber 16, a cracked gas outlet pipe 10, a catalyst 11, a preheating pipe 12, an alcohol rail 13, a methanol nozzle 14, and a cooling nozzle oil return pipe 15. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com