New energy cylinder sleeve and production method thereof

A cylinder liner and new energy technology, applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., can solve the problems of high explosion pressure, Euro VI emissions, etc., and achieve the effect of improving movement space, high wear resistance, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

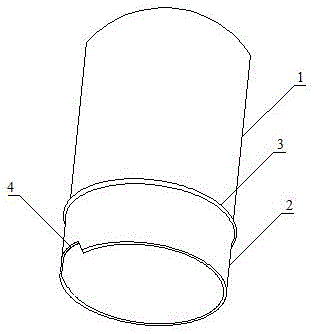

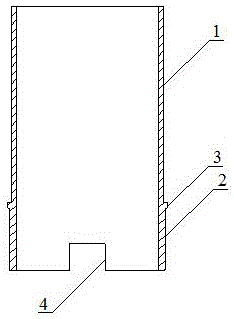

[0030] A new energy cylinder liner, such as figure 2 and 3 As shown, the cylinder liner includes an upper thin-walled section 1 and a lower thick-walled section 2. The connection between the thin-walled section 1 and the thick-walled section 2 is provided with a supporting shoulder 3, and the bottom end of the thick-walled section 2 There is a connecting rod avoidance groove 4; the cylinder liner structure adopts a middle support design, and the cylinder liner is press-fitted by the top of the thin-walled section 1 from the lower end of the cylinder hole and is gradually pressed upwards. Ying fit, the thick-walled section 2 is a clearance fit with the cylinder bore. In weight percent, the chemical composition of the cylinder liner is: 2.70% carbon, 1.60% silicon, 0.50% manganese, 0.20% phosphorus, 0.05% sulfur, 0.20% chromium, 0.20% copper, 0.30% nickel, 0.20% molybdenum, The balance is iron.

[0031] The production process of the above-mentioned new energy cylinder liner ...

Embodiment 2

[0044] A new energy cylinder liner, such as figure 2 and 3 As shown, the cylinder liner includes an upper thin-walled section 1 and a lower thick-walled section 2. The connection between the thin-walled section 1 and the thick-walled section 2 is provided with a supporting shoulder 3, and the bottom end of the thick-walled section 2 There is a connecting rod avoidance groove 4; the cylinder liner structure adopts a middle support design, and the cylinder liner is press-fitted by the top of the thin-walled section 1 from the lower end of the cylinder hole and is gradually pressed upwards. Ying fit, the thick-walled section 2 is a clearance fit with the cylinder bore. In weight percent, the chemical composition of the cylinder liner is: 2.90% carbon, 1.80% silicon, 0.70% manganese, 0.35% phosphorus, 0.07% sulfur, 0.35% chromium, 0.30% copper, 0.40% nickel, 0.40% molybdenum, The balance is iron.

[0045] The production process of the above-mentioned new energy cylinder liner ...

Embodiment 3

[0057] A new energy cylinder liner, such as figure 2 and 3 As shown, the cylinder liner includes an upper thin-walled section 1 and a lower thick-walled section 2. The connection between the thin-walled section 1 and the thick-walled section 2 is provided with a supporting shoulder 3, and the bottom end of the thick-walled section 2 There is a connecting rod avoidance groove 4; the cylinder liner structure adopts a middle support design, and the cylinder liner is press-fitted by the top of the thin-walled section 1 from the lower end of the cylinder hole and is gradually pressed upwards. Ying fit, the thick-walled section 2 is a clearance fit with the cylinder bore. In weight percent, the chemical composition of the cylinder liner is: 3.20% carbon, 2.10% silicon, 0.90% manganese, 0.50% phosphorus, 0.10% sulfur, 0.50% chromium, 0.50% copper, 0.40% nickel, 0.60% molybdenum, The balance is iron.

[0058] The production process of the above-mentioned new energy cylinder liner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com