Oxygen sensor-based urea jet control device for diesel and control method for jet control device

A technology of oxygen sensor and control device, which is applied in the field of diesel engine post-processing SCR control and diesel engine urea injection control device, which can solve the problems of inconsistent initial state and NOx amount change, etc., and achieve the effect of solving insufficient reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

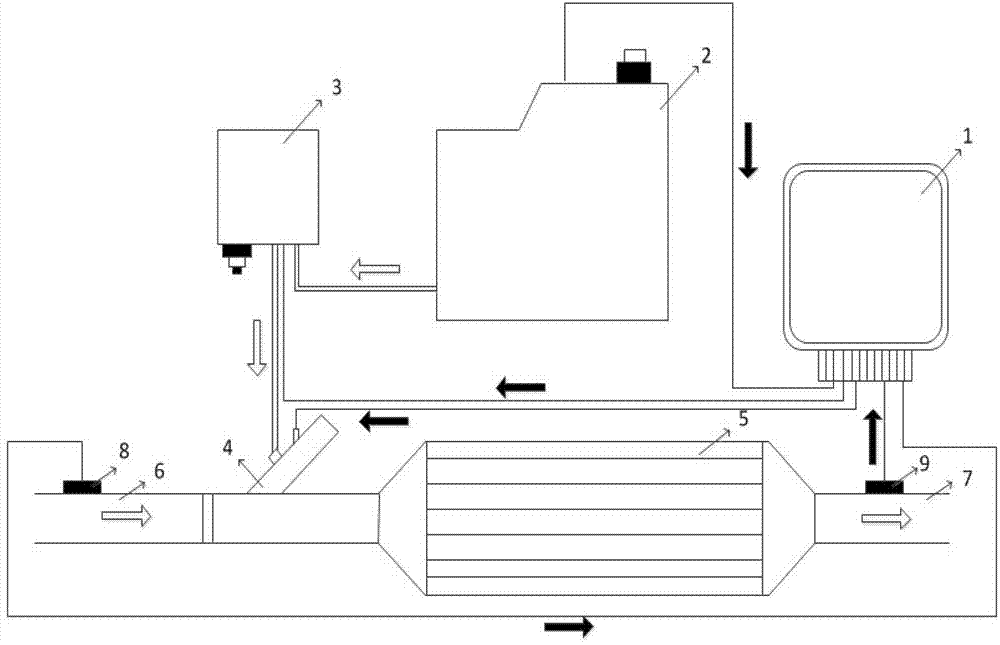

[0029] The new urea injection control device based on oxygen sensor provided by the present invention includes ECU1, urea tank 2, urea pump 3, urea nozzle 4, SCR tank 5, SCR tank front exhaust pipe 6, SCR tank rear exhaust pipe 7 , SCR tank front oxygen sensor 8, SCR tank rear oxygen sensor 9.

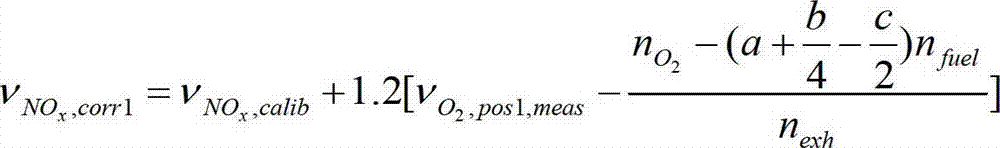

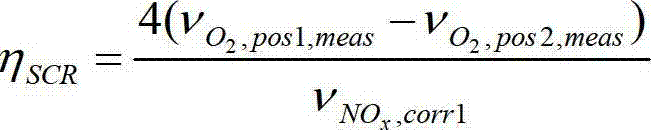

[0030]An oxygen sensor 8 in front of the SCR box and an oxygen sensor 9 behind the SCR box are respectively installed on the front exhaust pipe 6 of the SCR box and the rear exhaust pipe 7 of the SCR box. ECU1 is connected to the urea solution tank 2 to obtain the temperature and liquid level information of the urea solution tank, and control the working conditions of the urea solution tank 2; ECU1 is connected to the urea solution pump 3 and the urea solution nozzle 4, and combines the NOx correction algorithm before and after the SCR tank in the ECU to control the urea solution pump 3 works with urea nozzle 4 to realize closed-loop control of NO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com