Hydrogen engine

An engine and hydrogen technology, applied in gaseous engine fuel, engine components, engine control, etc., can solve the problems that engine fuel consumption and emissions cannot be further optimized and improved, and the development of traditional gasoline engines is difficult, and achieves high flame propagation speed and ignition limit. Wide, reduced use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

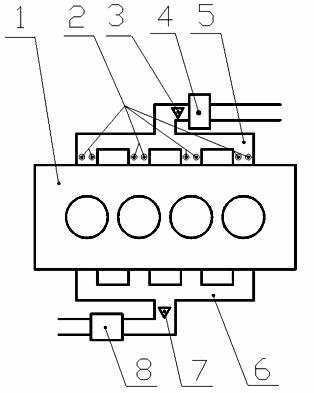

[0017] Such as figure 2 As shown, the engine is a hydrogen engine with a multi-point sequential injection electronic control system, the electronic control system is mounted on the engine, the hydrogen gas rail 14 is arranged on the intake manifold 5, and eight hydrogen nozzles are distributed on the hydrogen gas rail 2. Evenly distributed on four cylinders. The hydrogen pressure and temperature sensor 12 is installed on the hydrogen gas rail 14 , the intake air pressure and temperature sensor 3 is arranged at the front end of the plenum chamber of the intake manifold 5 , and the wide-area oxygen sensor 7 is arranged on the exhaust manifold 6 . The electronic throttle valve 4 is installed at the front end of the intake manifold 5. In addition, an NSR catalytic converter for processing NOx is arranged on the exhaust manifold of the exhaust system. The ECU, hydrogen driver and the entire hydrogen supply system are arranged in the vehicle cab or engine compartment.

[0018] se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com