Methanol and hydrogen dual-fuel power system

A power system and dual-fuel technology, applied in the direction of charging system, combustion engine, internal combustion piston engine, etc., can solve the problems that are not conducive to improving the fuel consumption rate of the engine emission level, limited application in cold winter regions, and difficult to achieve lean combustion conditions, etc. problems, to achieve the effect of improving energy utilization, low cost and high emission level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

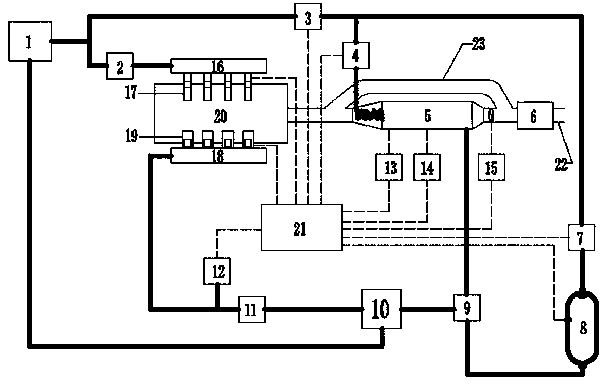

[0030] A methanol and hydrogen dual fuel power system, the methanol and hydrogen dual fuel power system includes an engine 20, a hydrogen production device 5, a methanol tank 1 and a cold start electric heating hydrogen production device 8;

[0031] The methanol tank communicates with the methanol injection rail 16 on the engine intake manifold, the methanol inlet of the cold-start electric heating hydrogen production device, and the methanol inlet pipe of the hydrogen production device through pipelines. The methanol inlet pipe of the hydrogen device is connected to the hydrogen production device of the engine exhaust pipe 22, and the gas outlet pipeline of the cold start electric heating hydrogen production device is connected to the production device through one end of the electromagnetic three-way check valve 9. The gas inlet of the hydrogen device is connected, and the other end is connected with the gas cooling and gas-liquid separation device 10. The methanol outlet of t...

Embodiment 2

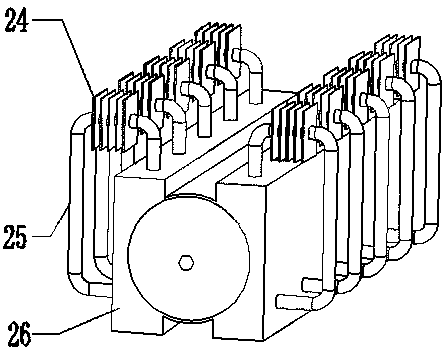

[0033] According to the methanol and hydrogen dual-fuel power system described in Embodiment 1, the gas cooling and gas-liquid separation device includes a cooling fin 24, a loop heat pipe 25, a heat pipe evaporation chamber 26, a gas inlet 27, a liquid outlet 28 and a gas Outlet 29, the loop heat pipe communicates with the heat pipe evaporation chamber, the loop heat pipe is provided with cooling fins, the gas inlet and the gas outlet are distributed in the gas cooling and gas-liquid separation device On both sides, the liquid discharge port is at the lower part of the gas cooling and gas-liquid separation device.

Embodiment 3

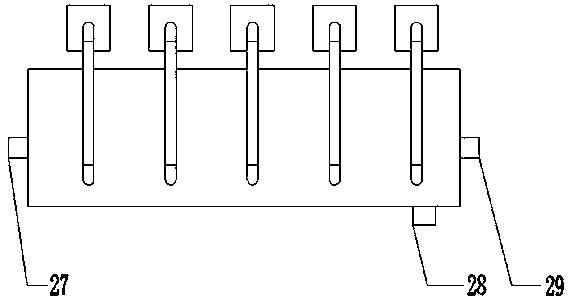

[0035] According to the methanol and hydrogen dual-fuel power system described in embodiment 1 or 2, the cold start electric heating hydrogen production device includes a methanol inlet 30, a plurality of PTC thermistors 31, a hydrogen production catalyst 33 and a gas outlet 36, the A plurality of PTC thermistors arranged in parallel are fixed inside the cold-start electric heating hydrogen production device, methanol vapor channels are formed between the plurality of PTC thermistors, and the alcohol vapor channels are filled with the Hydrogen production catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com