Vertical spiral powder conveyer

A powder feeder, vertical technology, applied in the field of powder conveying machinery for spraying, can solve the problems of large conveying volume, difficult continuity, poor continuity and uniformity of powder feeding, and achieve the effect of avoiding blowback and air pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

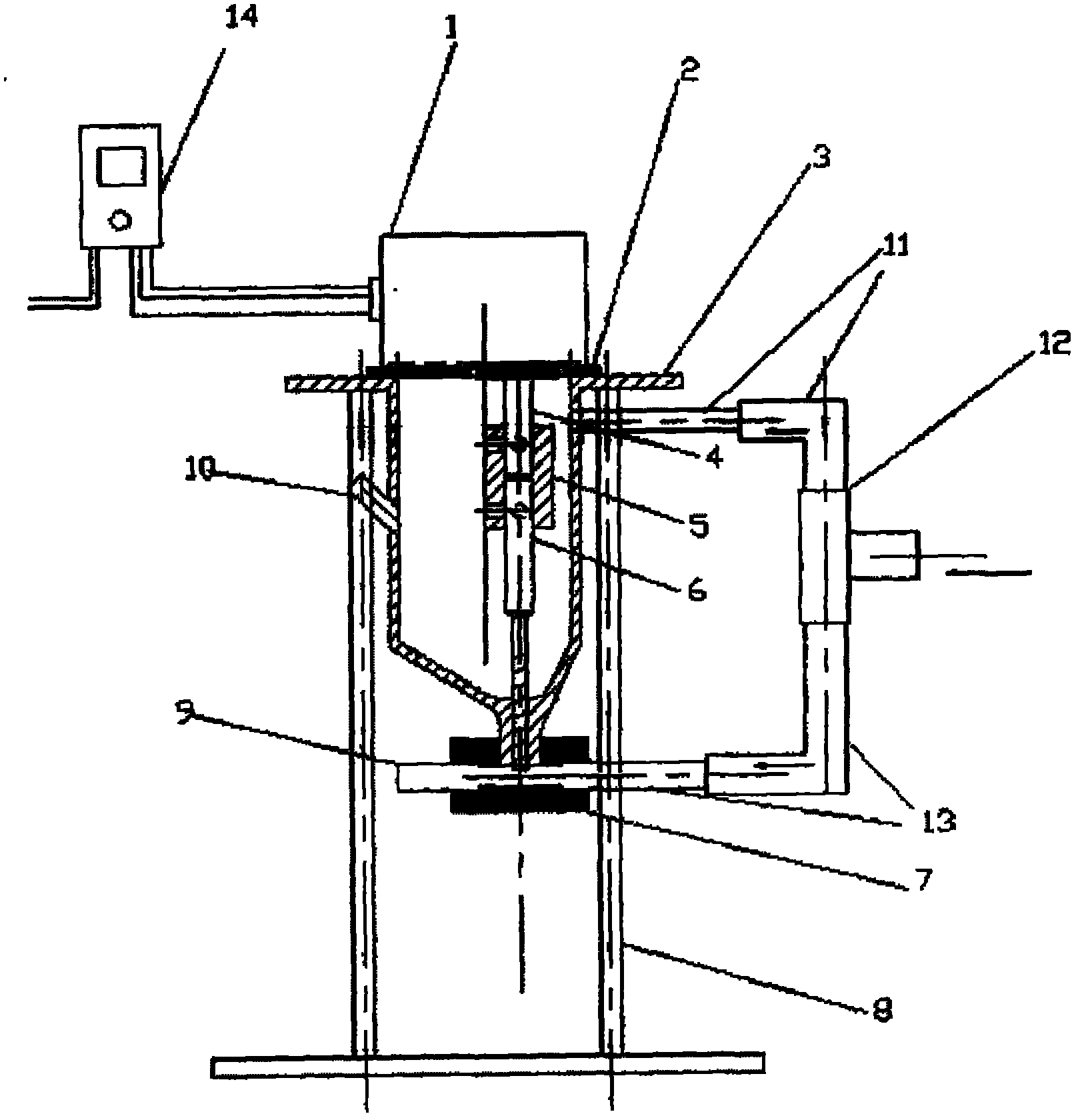

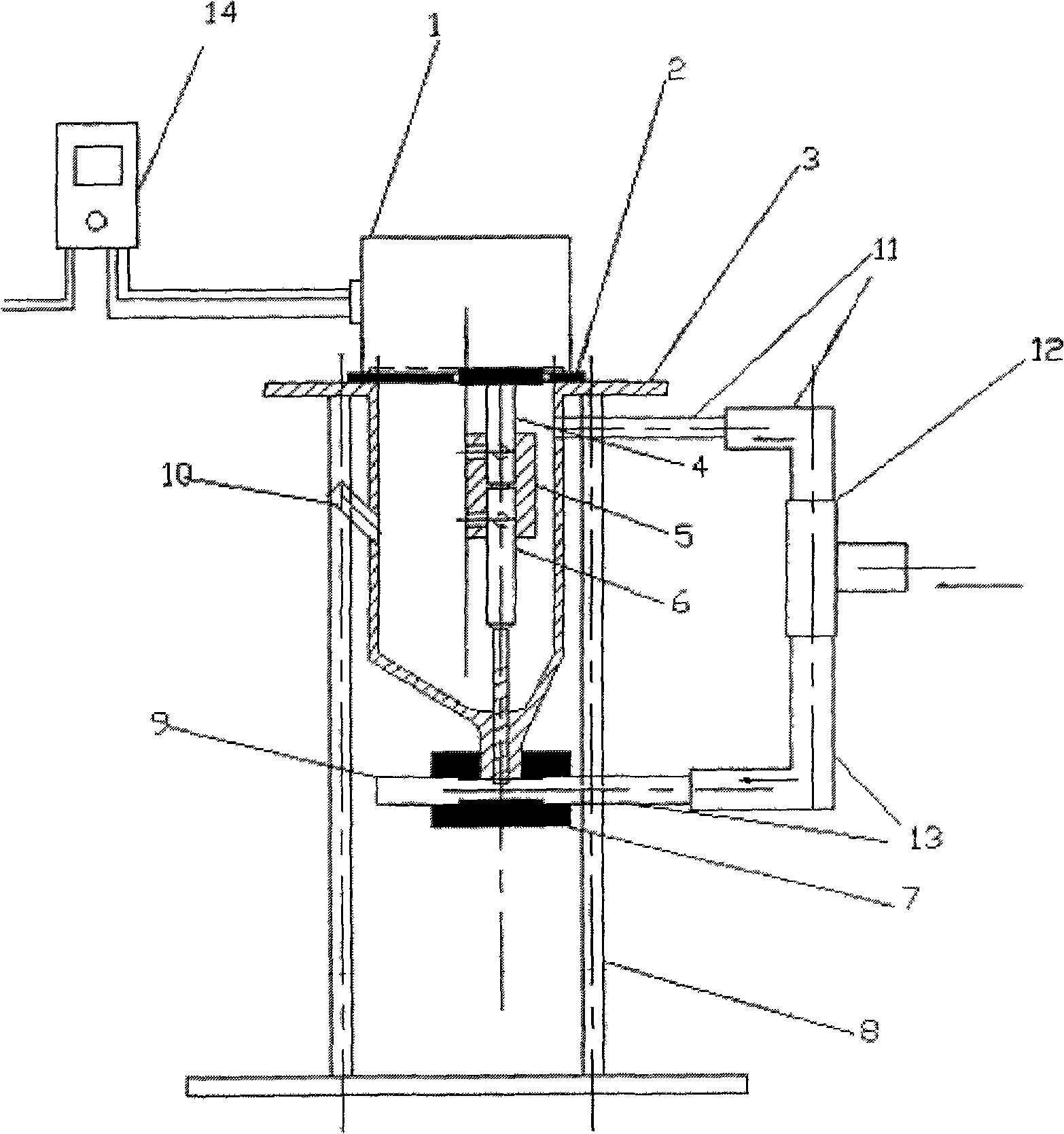

[0009] Such as figure 1 As shown, the present invention is a micro-controllable vertical screw powder feeder. The motor 1 is placed on the silo 3 and connected to the speed governor 14. The gasket 2 is placed between the motor 1 and the silo 3. The seat 8 is placed in the lower part of the silo 3, the coupling 5 is placed inside the silo 3, and connects the motor spindle 4 and the screw rod 6; the lower end of the screw rod 6 extends into the feeding tee 7, and the powder is transported to the feeder through its rotation. In the feeding tee 7; the feed pipe 10 is placed on one side of the wall of the silo 3; one end of the feeding tee 7 is connected to the lower part of the hopper 3, and the other two ends are respectively connected to the inlet pipe 13 and the discharge pipe 9; One end of the gas distribution tee 12 is connected to the pipeline of the gas cylinder, and the other two ends are respectively connected with the inlet pipe 13 and the balance air pipe 11, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com