Radiator core support

A radiator and core technology, applied in heat exchanger shells, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as reducing the cooling performance of condensers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, the overall structure of the radiator core support of this embodiment will be described.

[0028] The radiator core bracket of this embodiment is arranged at the front part of the vehicle body and constitutes a part of the vehicle body.

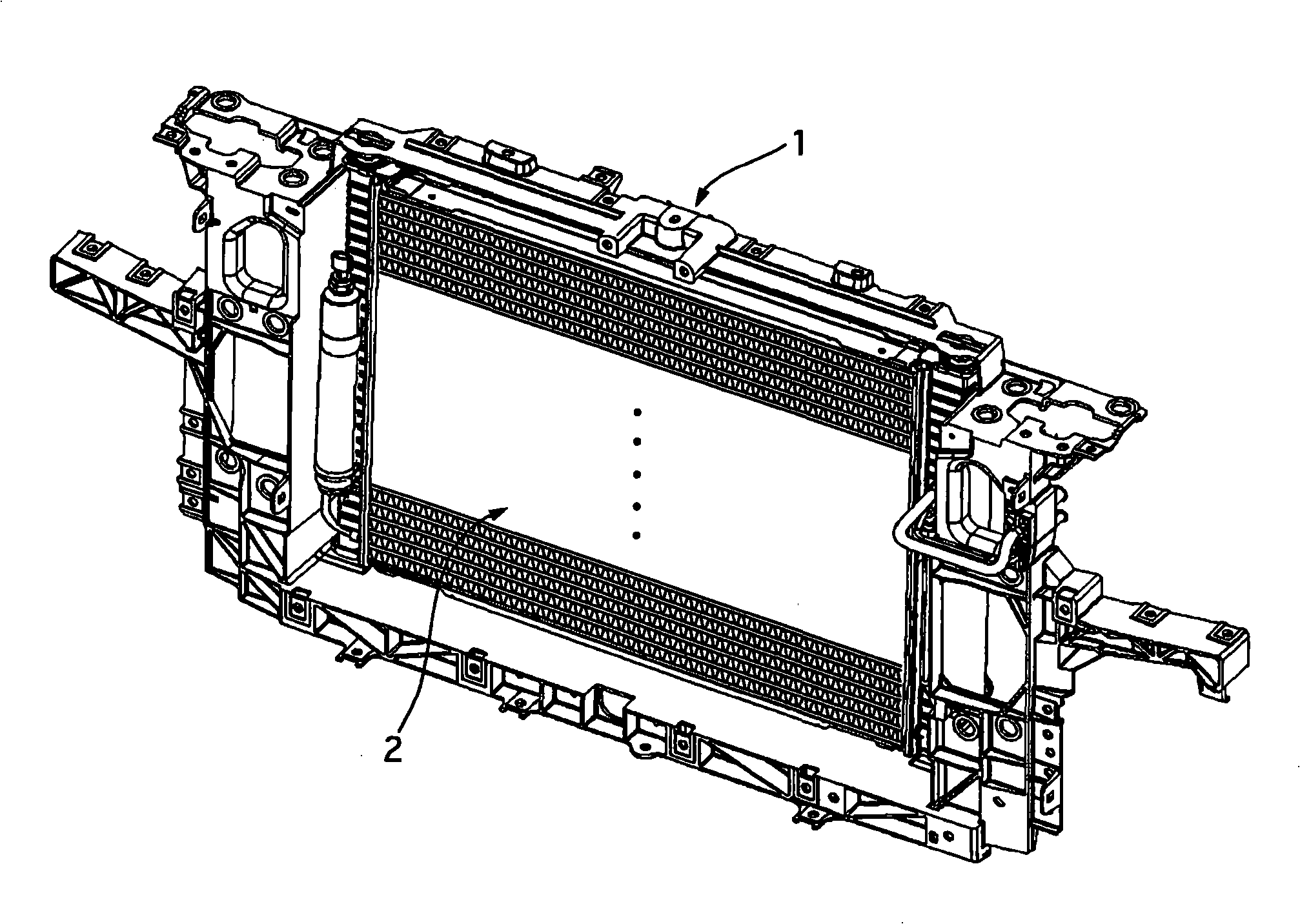

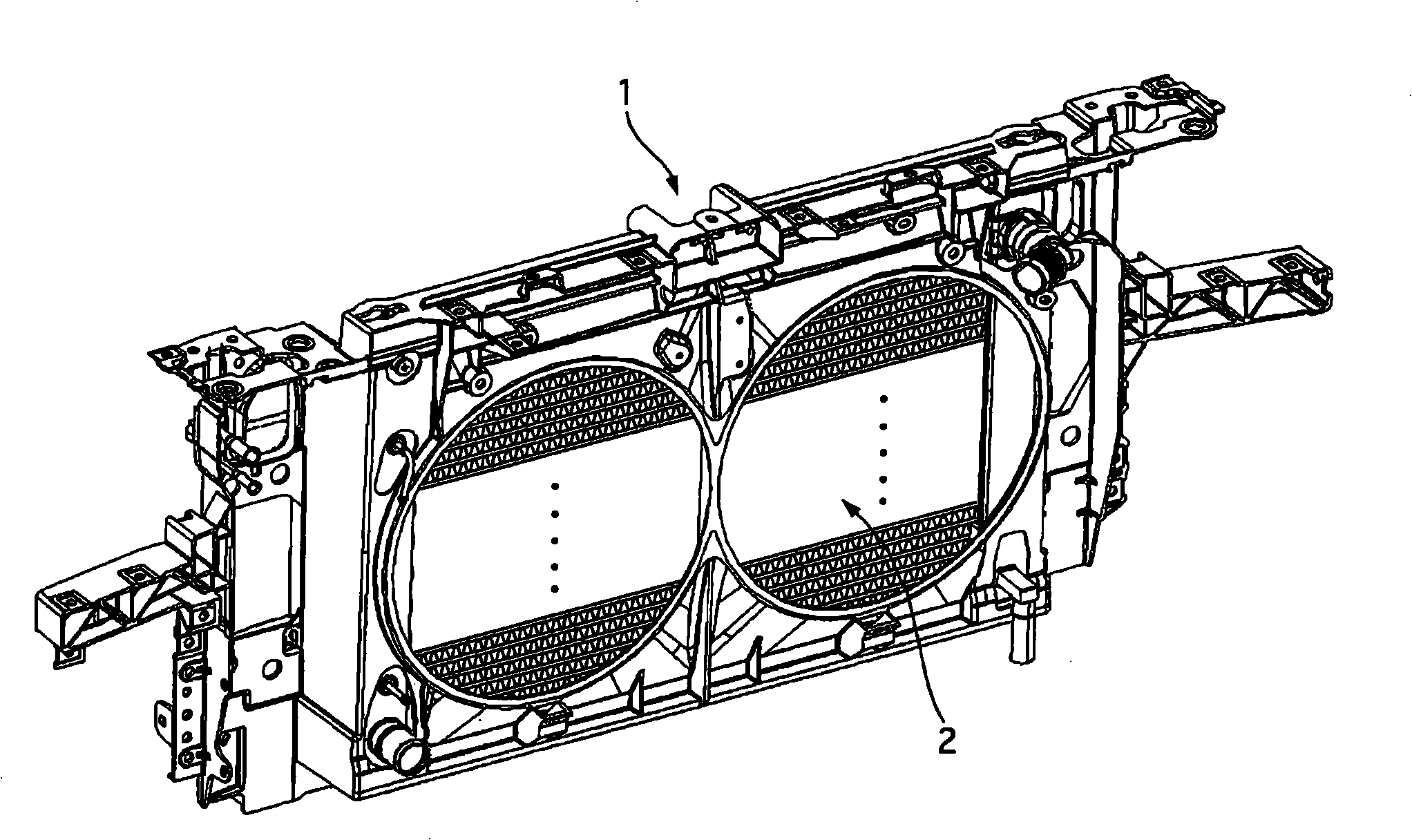

[0029] Such as figure 1 , figure 2 As shown, the radiator core support 1 of this embodiment has an integrated heat exchanger 2 composed of a condenser and a radiator.

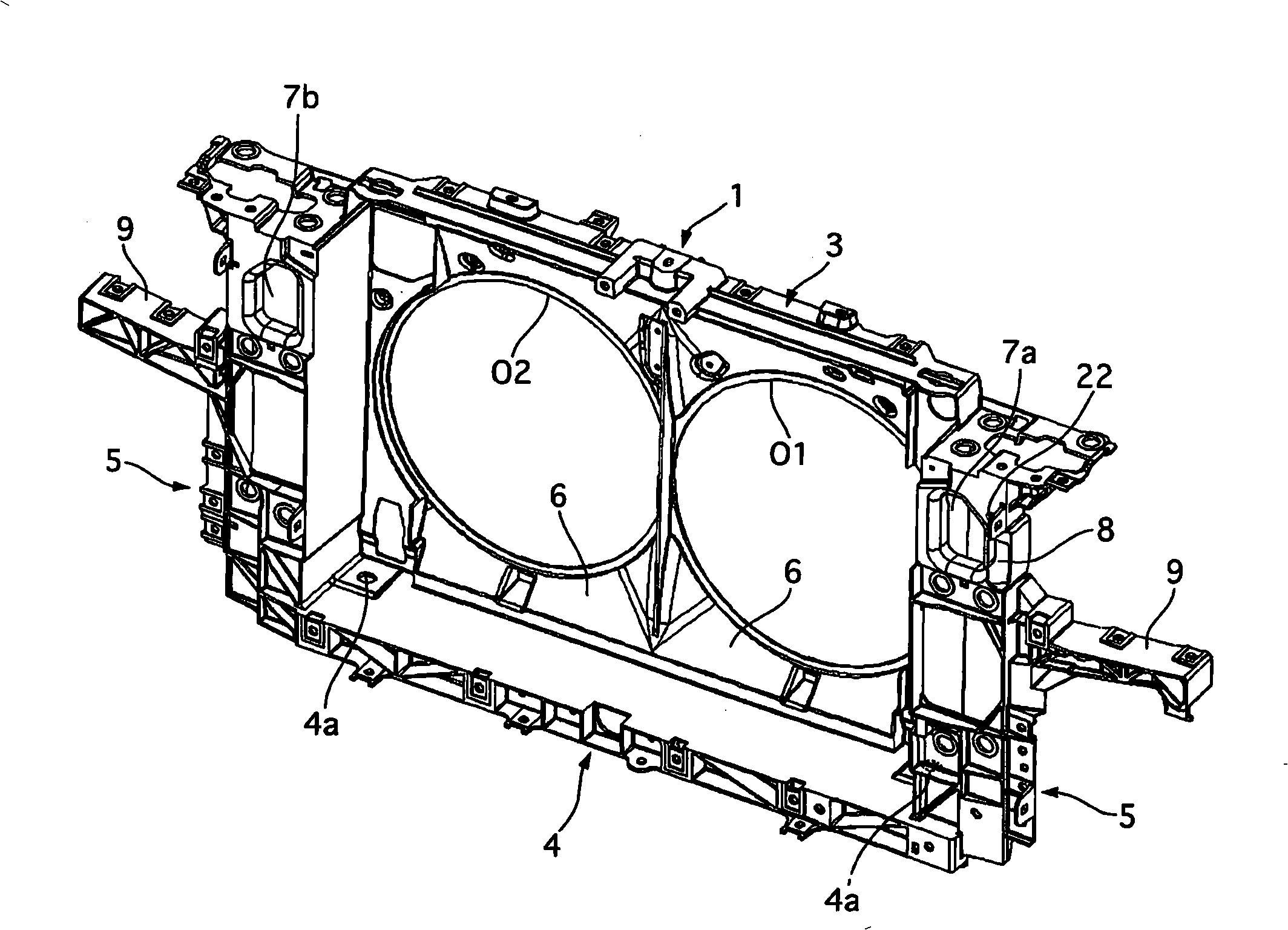

[0030] Such as image 3 , Figure 4 As shown, the radiator core support 1 is composed of a radiator core support upper part 3 extending in the vehicle width direction, a radiator core support lower part 4 arranged in parallel with the radiator core support upper part 3, and a radiator core support lower part 4 arranged in parallel with the radiator core support. The left and right radiator core support side parts 5, 5 that are combined with the two ends of the sub-support upper part 3 and the radiator core support lower part 4, from the above-mentioned radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com