Continuous cooking anti-reverse spraying device

A technology of anti-reverse injection and pneumatic cylinder, which is applied in the direction of digester, textile and paper making, fiber raw material processing, etc., can solve the problems of continuous cooking and feeder reverse injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

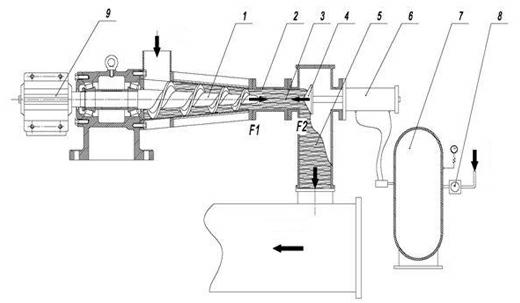

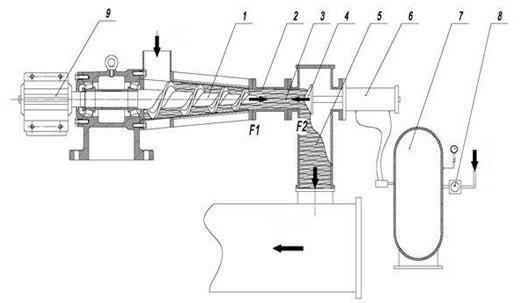

[0026] Attached below figure 1 And specific examples further illustrate the content of the present invention.

[0027] Such as figure 1 As shown, the present invention is mainly made up of screw shaft 1, throat pipe 2, thrust valve 4, T-shaped pipe 5, pneumatic cylinder 6, surge tank 7, gas source stabilizer 8 and frequency conversion transmission motor 9. The throat is equipped with a pressure sensor, and the pressure regulator tank is equipped with accessories such as an air pressure indicator. The pressure sensor and the frequency conversion motor of the present invention are interlocked and connected to the automatic control system, and can perform stepless speed regulation on the main shaft according to pressure changes and output requirements.

[0028] When working: the screw shaft rotates towards the set direction at a certain speed, and the raw material is pushed from the continuous feeder to the T-shaped pipe to generate thrust F1; a thrust valve core on the T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com