Trigger, trigger system and trigger method

A trigger and sensor technology, which is applied in the field of arc welding, can solve the problems of fuzzy images of the molten pool and the inability to take pictures of weld seams, etc., and achieve the effects of accurate digital voltage sensing signals, improved clarity, and good isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

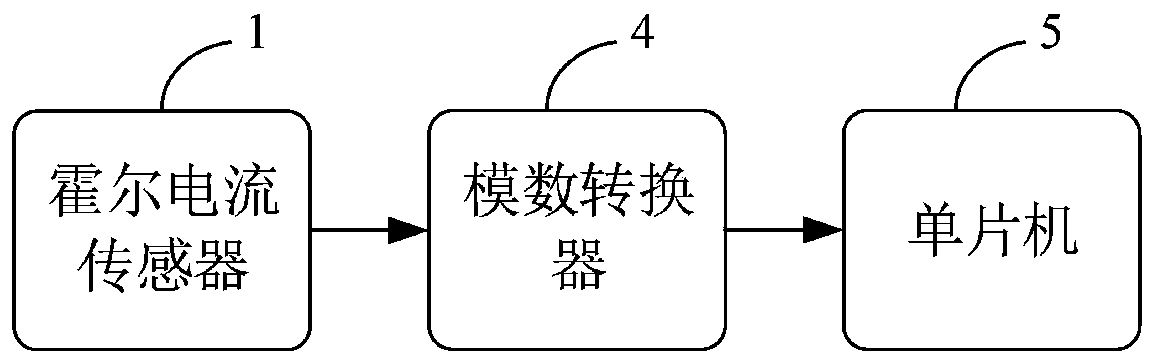

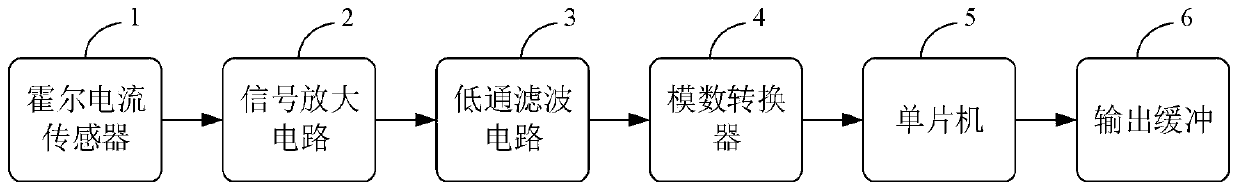

[0041] Such as figure 1 As shown, a trigger, including:

[0042] The Hall current sensor 1 is used to convert the current signal of the welding machine into a voltage sensing signal.

[0043] In the above embodiments, the use of the Hall current sensor has a good isolation effect, which can ensure that the acquired pulse signal is not affected by the welding machine.

[0044] The analog-to-digital converter 4 is configured to perform analog-to-digital conversion on the voltage sensing signal to generate a digital voltage sensing signal.

[0045] In the above embodiments, after the voltage sensing signal is obtained, the voltage sensing signal is converted to analog to digital by an analog-to-digital converter to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com