Powder metallurgy brake flat and method of manufacturing the same

A technology of powder metallurgy and brake pads, which is applied in the field of powder metallurgy brake pads and its preparation, can solve the problems of large wear of the pair, affect product matching, and increase prices, and achieve the effects of not easy to burn out, good safety performance, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

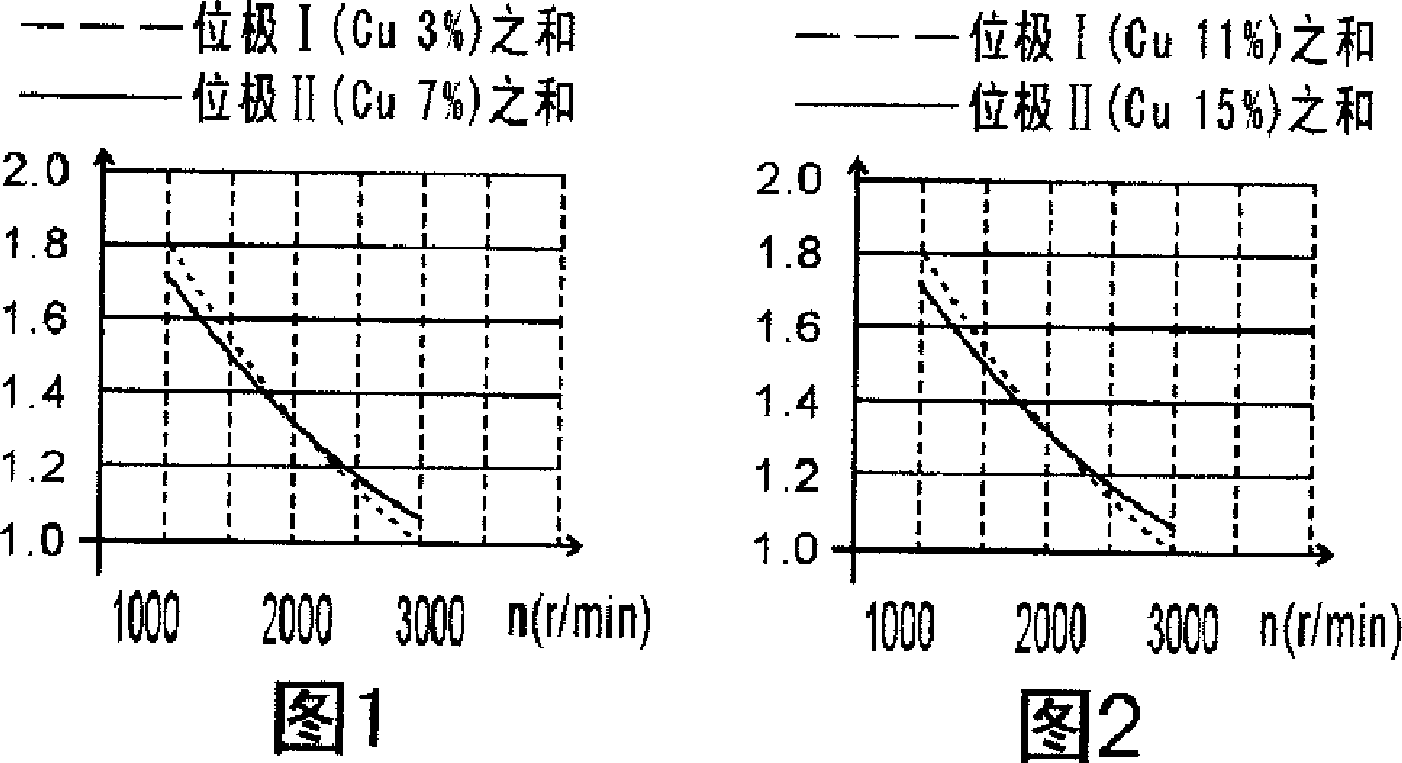

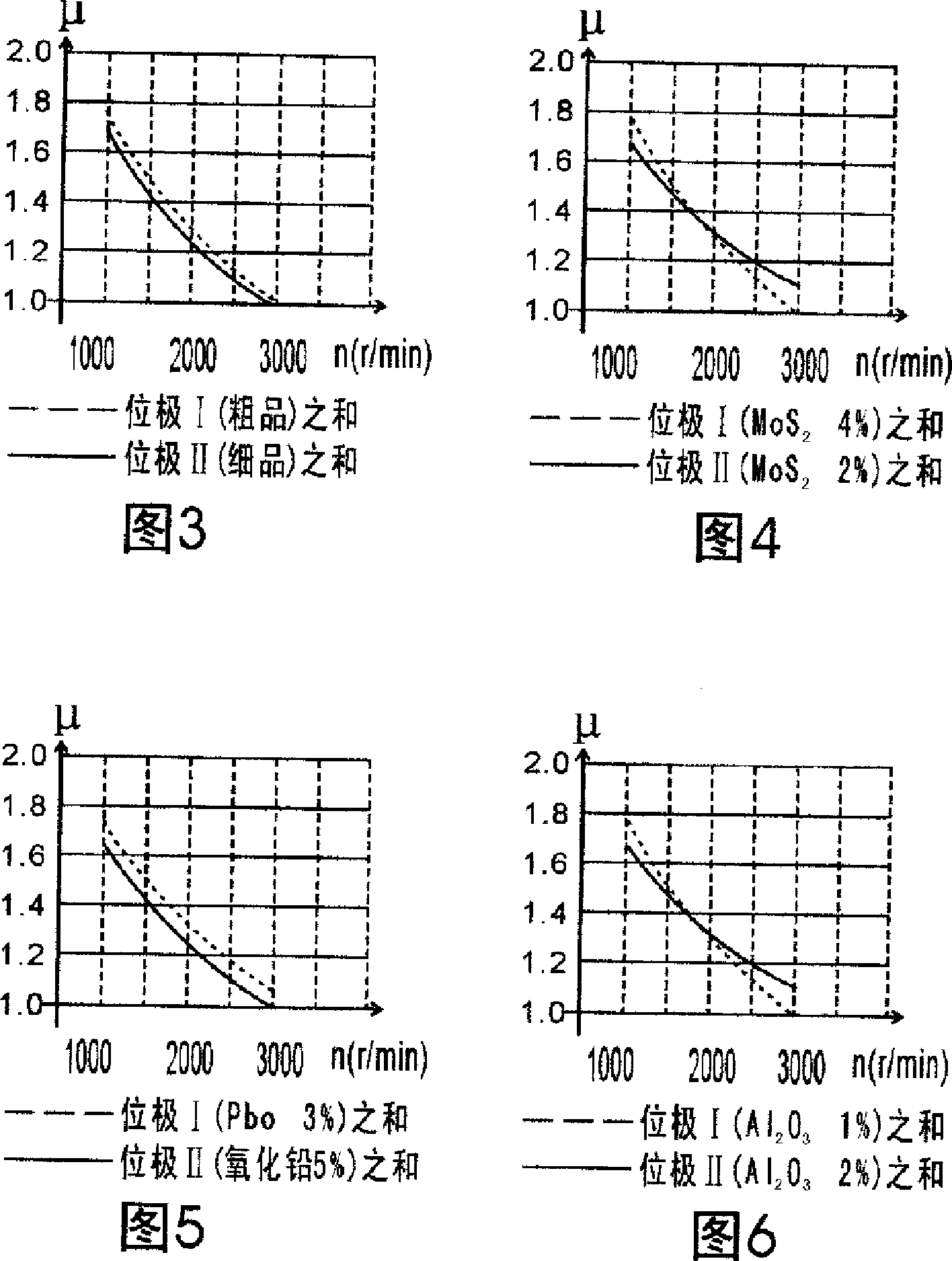

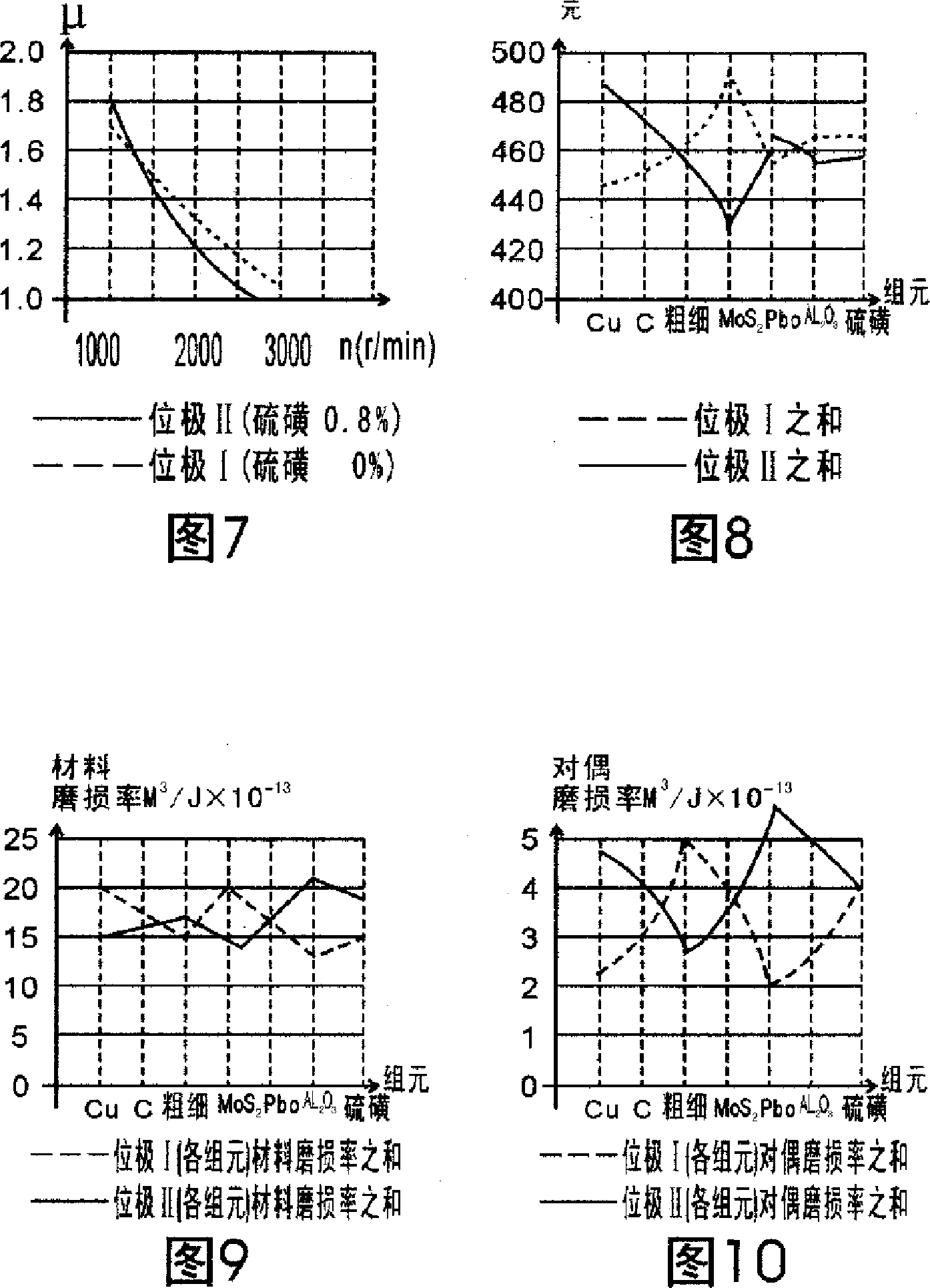

[0022] Test component factor table of the present invention:

[0023] component factor

graphite

Graphite particle size

Molybdenum disulfide

Aluminum oxide

Pole I

3%

11%

Crude

4%

1%

3%

0

Pole II

(upper limit)

7%

15%

detail

2%

2%

5%

0.8%

[0024] Note: Coarse crystals in graphite particle size mean that the ratio of -50 mesh to -80 mesh content is 1:1

[0025] Fine crystal means -50, -80, -200 mesh content ratio is 9:9:2

[0026] In order to reduce the number of tests, the present invention only selects the change of material content, while other process parameters such as mixing method, pressing pressure, sintering temperature, etc. are fixed. From the determination of the above parameter ranges and the table of factor positions, it can be seen that the main The parameter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com