Test bed for brake noise of high-speed train brake disc

A technology for noise testing and high-speed trains, applied in railway vehicle testing and other directions, can solve the problems of noise reduction, no high-speed train brake disc braking noise, noise pollution along the line, etc., and achieve the effect of reducing braking noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

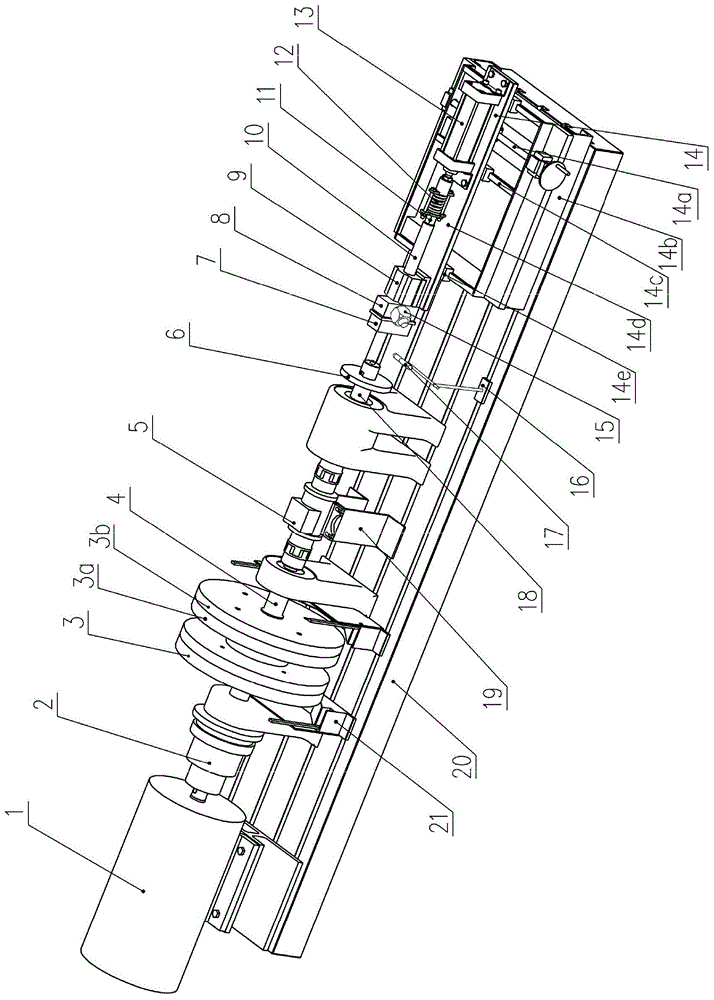

[0024] figure 1 Shown is a brake noise test bench for brake discs of high-speed trains. Its structural features are: a variable frequency motor 1 is installed on the left side of the base 20, and the output shaft of the variable frequency motor 1 passes through an electromagnetic clutch 2, a flywheel shaft 4, and a torque sensor in sequence. 5 is connected with the brake shaft 18; the right end of the brake shaft 18 is connected with the brake disc 6, the flywheel group 3 is fixed on the flywheel shaft 4, and the torque sensor 5 is fixed on the base 20 through the sensor base 19;

[0025] The right side of base 20 is equipped with slide table 14 that can move back and forth, and cylinder 13 is installed on the right side of slide table 14; The clamp 8 holding the brake pad 7 is connected; the middle part of the guide rod 10 is supported on the slide table 14 through the linear bearing 9; the side of the clamp 8 is equipped with a three-dimensional acceleration sensor 15;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com