Metallic matrix spindle brake pad for wind driven generator and preparation method thereof

A technology of wind power generators and brake pads, applied in the field of brake pads, can solve problems such as lack of resources and inconformity with national sustainable development strategic decisions, and achieve the effects of improving mechanical properties, achieving environmental friendliness, and stabilizing friction coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

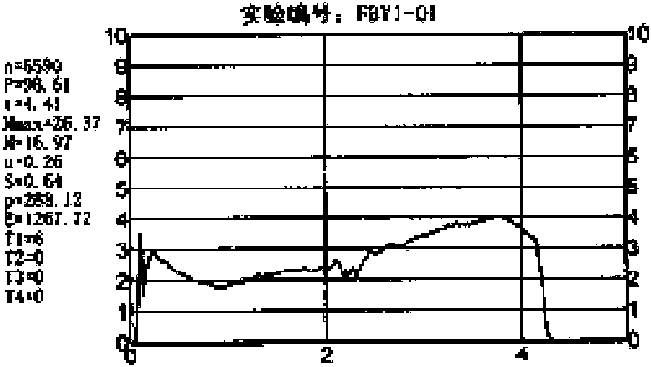

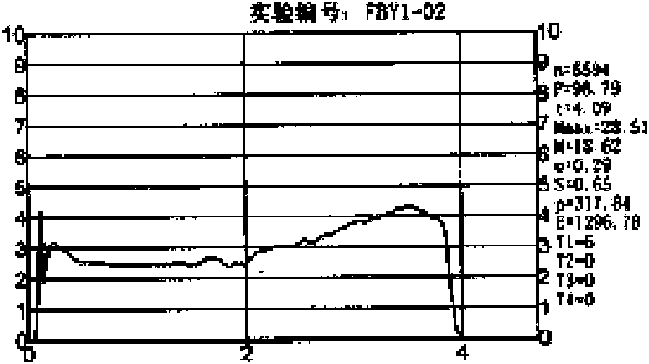

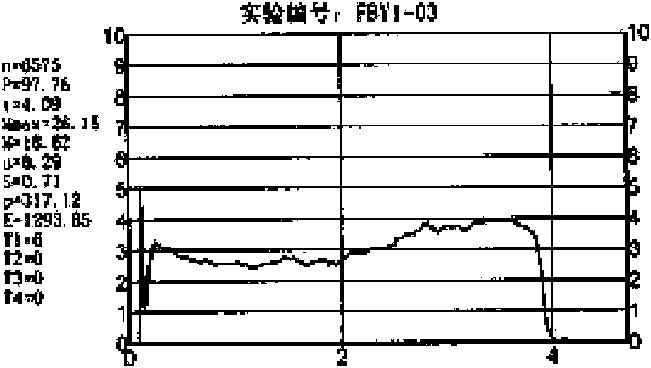

Image

Examples

Embodiment 1

[0037] The formula description of the wind power generator spindle brake pad provided by the invention

[0038] Copper powder 50 (wt.%), its particle size is ≤70μm, copper powder purity ≥98%,

[0039] Tin powder 5 (wt.%), the particle size of which is ≤70μm,

[0040] Iron powder 20 (wt.%), the particle size is ≤70 μm, and the purity of iron powder is ≥98.5%;

[0041] Chopped steel fibers 5 (wt.%), the length of which is 2-5 mm, and the diameter is 50-150 μm;

[0042] Brass fiber 5 (wt.%), the length of which is 2.5-3.5 mm, and the diameter is 100-200 μm;

[0043] High alumina ceramic fiber 3 (wt.%), the length of which is 0.5-1.5 mm, and the diameter is 50-100 μm;

[0044] Sulfur 1 (wt.%), the particle size of which is ≤200μm;

[0045] Aluminum oxide 2 (wt.%), the particle size of which is 70 μm to 200 μm;

[0046] Silica 3 (wt.%), the particle size of which is 70 μm to 200 μm;

[0047] Flake graphite 2 (wt.%), fixed carbon content ≥ 90%, ash content ≤ 10%, and its parti...

Embodiment 2

[0057] The formula description of the wind power generator spindle brake pad provided by the invention

[0058] Copper powder and tin powder 50%, its particle size is ≤70μm, copper powder purity ≥98%, wherein copper powder: tin powder=10:1;

[0059] Iron powder 20 (wt.%), the particle size is ≤70 μm, and the purity of iron powder is ≥98.5%;

[0060] Chopped steel fibers 5 (wt.%), the length of which is 2-5 mm, and the diameter is 50-150 μm;

[0061] Brass fiber 4 (wt.%), the length of which is 2.5-3.5 mm, and the diameter is 100-200 μm;

[0062]High alumina ceramic fiber 4 (wt.%), its length is 0.5~1.5mm, and its diameter is 50~100μm;

[0063] Aluminum oxide 5 (wt.%), the particle size of which is 70 μm to 200 μm;

[0064] Silica 5 (wt.%), the particle size of which is 70 μm to 200 μm;

[0065] Flake graphite 3 (wt.%), fixed carbon content ≥ 90%, ash content ≤ 10%, and its particle size is ≤ 70μm;

[0066] Granular graphite 4 (wt.%), fixed carbon content ≥ 95%, ash conten...

Embodiment 3

[0075] The formula description of the wind power generator spindle brake pad provided by the invention

[0076] Copper powder and tin powder 40wt.%, its particle size is ≤ 70 μm, copper powder purity ≥ 98%, wherein copper powder: tin powder = 10: 1;

[0077] Iron powder 20 (wt.%), the particle size is ≤70 μm, and the purity of iron powder is ≥98.5%;

[0078] Chopped steel fiber 10 (wt.%), its length is 2~5mm, and its diameter is 50~150μm;

[0079] Brass fiber 10 (wt.%), its length is 2.5~3.5mm, and its diameter is 100~200μm;

[0080] High alumina ceramic fiber 3 (wt.%), the length of which is 0.5-1.5 mm, and the diameter is 50-100 μm;

[0081] Aluminum oxide 2 (wt.%), the particle size of which is 70 μm to 200 μm;

[0082] Silica 3 (wt.%), the particle size of which is 70 μm to 200 μm;

[0083] Flake graphite 8 (wt.%), fixed carbon content ≥ 90%, ash content ≤ 10%, and its particle size ≤ 70μm;

[0084] Granular graphite 4 (wt.%), fixed carbon content ≥ 95%, ash content ≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com