Few-metal-content low-density noise-free resin based composite friction material and preparation method

A composite friction material, low-density technology, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of high metal content, energy consumption, difficult to eliminate, etc., to reduce material density and low manufacturing costs. , the effect of low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

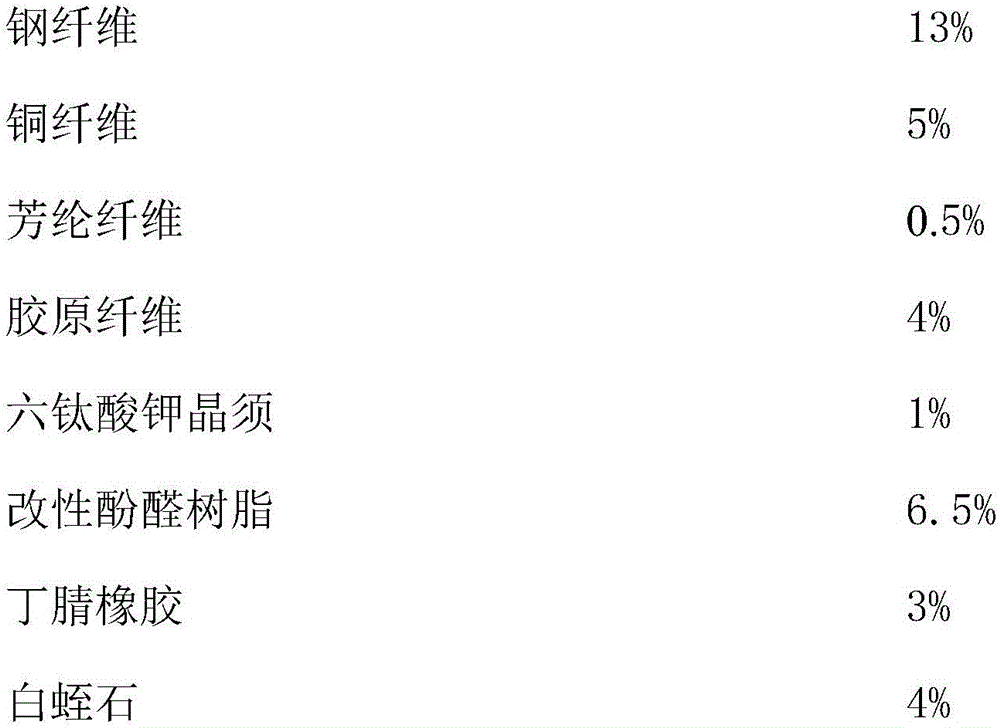

[0029] Prepare friction material raw materials according to the following ratio:

[0030]

[0031]

[0032] According to above formula design, process according to the following steps:

[0033] Ingredients: Weigh each component according to the above ratio;

[0034] Mixing: Put the aramid fiber into the high-speed mixer to disperse for 1 minute, and then put other materials except expanded graphite and natural graphite into the mixer for 20 minutes. It is better to add expanded graphite, Natural graphite was dropped into the mixer and mixed for 5 minutes;

[0035] Molding: Weigh the mixture according to the product model of the brake pad, pour it into the hot pressing mold, and press the pressure at 180-240kgf / cm 2 ,The hot-pressing temperature is 140-150°C, exhaust 3-6 times, and the holding time depends on the thickness of the brake pad, generally 200-240s;

[0036] Heat treatment: rise from room temperature to 120°C within half an hour, then 120°C for one hour, 130...

Embodiment 2

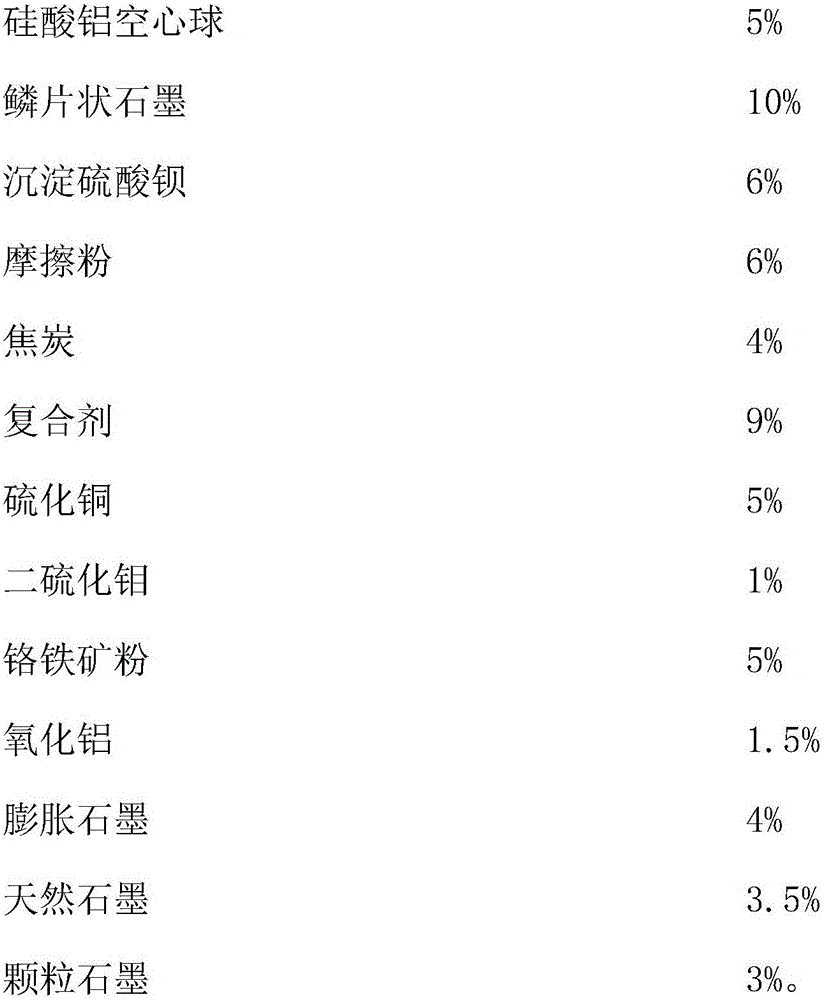

[0039] Prepare friction material raw materials according to the following ratio:

[0040]

[0041] Processing steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com