Method for preparing brake pad friction material by using rice and wheat straws

A technology of rice straw and friction materials, which is applied in the direction of friction linings, chemical instruments and methods, and other chemical processes, can solve problems such as unbearable for enterprises, increased costs, and rising graphite market prices, and achieve low recycling costs and structural Simple, enhanced braking performance and braking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

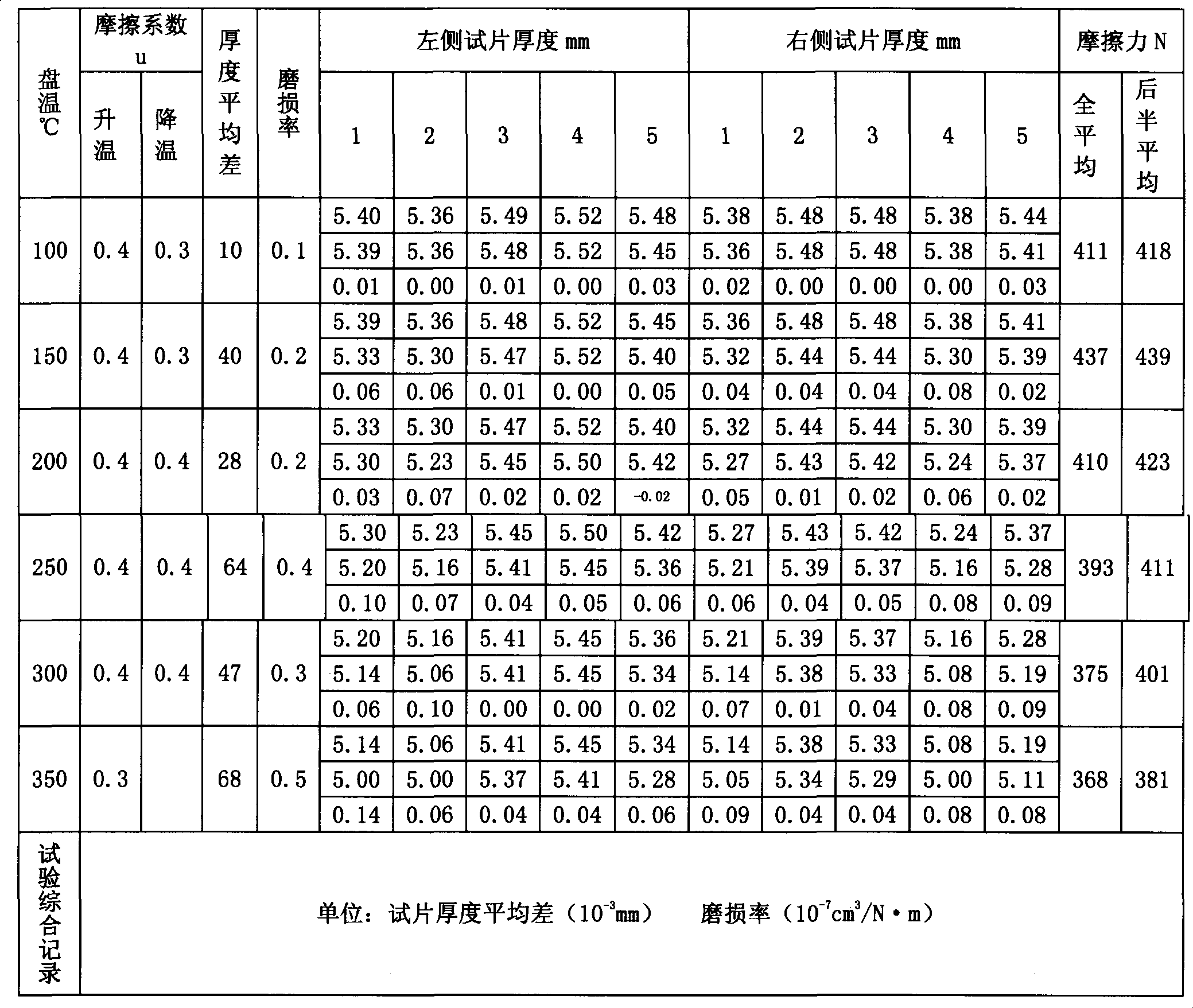

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment, the present invention is further described:

[0033] Make the rice and wheat straw charcoal powder friction material according to the following steps:

[0034] 1. Selection and cleaning of rice and wheat straw

[0035] Choose 1 ton of one-year rice and wheat straws, and those that are moldy and rotten cannot be used. After the newly harvested rice and wheat straws are recovered, the soil and impurities on the straws are cleaned.

[0036] 2. Drying

[0037] The washed rice and wheat straws are exposed to the sun or dried. If drying, the temperature should be controlled at 45±1℃, and the time should be controlled freely, but the surface of the rice and wheat straw should not be discolored, and the original color of the rice and wheat straw must be maintained. Use a wheat straw moisture meter to test, the moisture content is controlled at about 10%, and the maximum moisture content cannot exceed 13%.

[0038] Three, crush,

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com