Little-dust and low-metal friction material and preparation method thereof

A friction material and low-metal technology, applied in the direction of friction linings, chemical instruments and methods, mechanical equipment, etc., can solve problems such as difficulty in loosening, vibration, and easy corrosion, and achieve less brake heat decay and brake noise Low, not easy to rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Front brake pad one, the weight percentage of its component is as follows:

[0053] Nitrile modified phenolic resin 8%, nitrile rubber powder 5%, aramid fiber 2%, steel fiber 25%, cellulose fiber 4%, flake graphite 6%, artificial graphite 5%, barite 22%, friction Powder 3%, zircon powder 5%, expanded vermiculite 5%, diatomaceous earth 4%, petroleum coke 6%.

[0054] After the above-mentioned materials are processed according to the aforementioned processing method, they are tested on the rubbing material testing machine. The test results show that the friction coefficient at room temperature is 0.410, the friction coefficient at high temperature is 0.415, the grade is FF grade, the weight wear is 3.84%, and the thickness wear is 3.69%. The customer found that the ash falling situation has improved significantly.

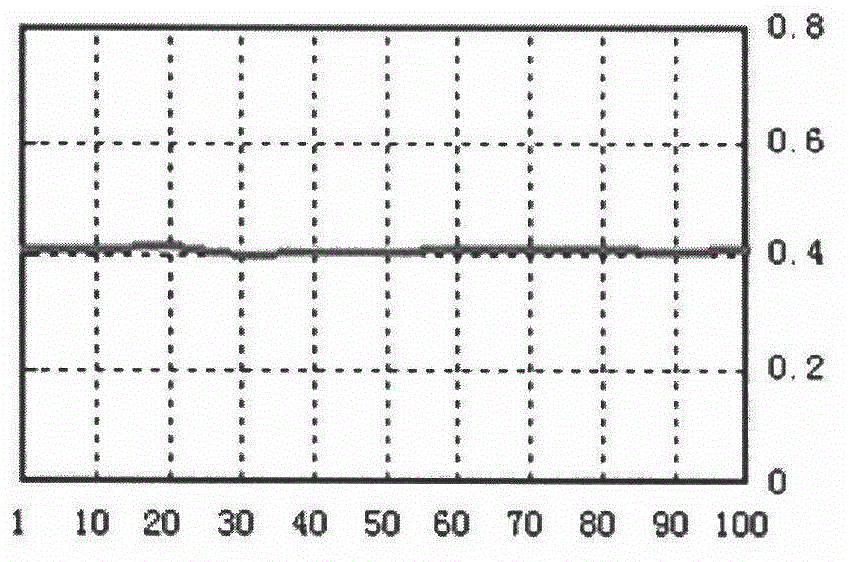

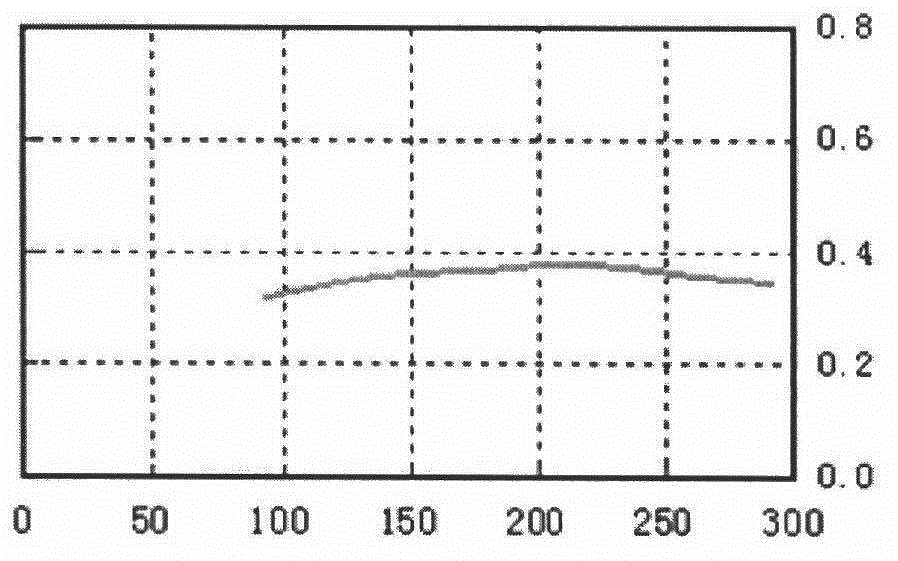

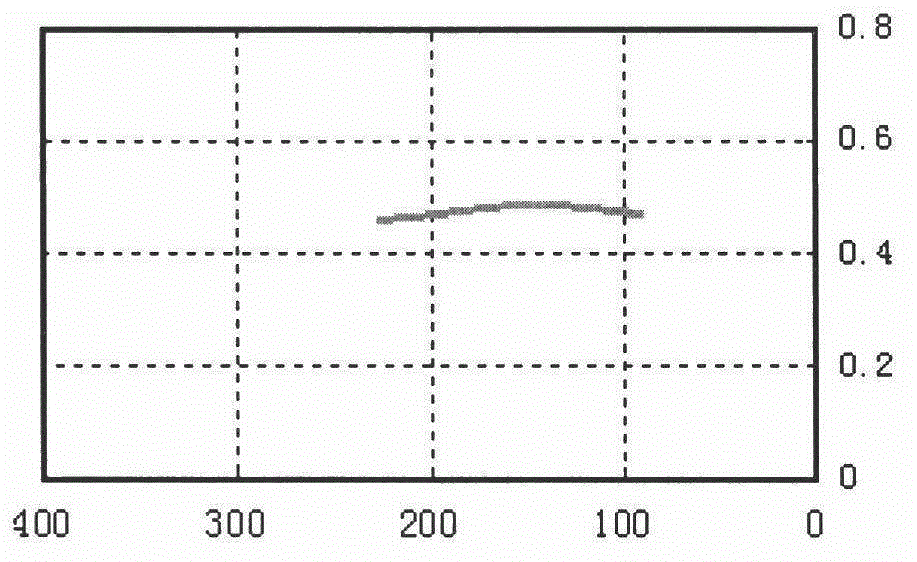

[0055] Such as Figure 1-5 The shown wear report curve, the first decay test curve, the first recovery test curve, the second recovery test curve and the se...

Embodiment 2

[0057] Front brake pad two, the weight percentage of its component is as follows:

[0058] Nitrile modified phenolic resin 6%, nitrile rubber powder 3%, aramid fiber 3%, steel fiber 30%, cellulose fiber 6%, flake graphite 8%, artificial graphite 7%, barite 18%, friction Powder 2%, zircon powder 4.5%, expanded vermiculite 4.5%, diatomaceous earth 3%, petroleum coke 5%.

[0059] After the above-mentioned materials are processed according to the aforementioned processing method, they are tested on the rubbing material testing machine. The test results show that the friction coefficient at room temperature is 0.412, the friction coefficient at high temperature is 0.42, the grade is FF grade, the weight wear is 3.89%, and the thickness wear is 3.75%. The customer found that the ash falling situation has improved significantly.

[0060] The wear report curve, the first decay test curve, the first recovery test curve, the second recovery test curve and the second decay test curve ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com