Preparation method of graphite phase carbon nitride fluorescent powder with controllable fluorescence emission wavelength

A fluorescent emission and fluorescent powder technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve the problems of low reserves of fluorescent powder materials, limited industrialization, unfriendly environment, etc., and achieve good fluorescent performance , controllable yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

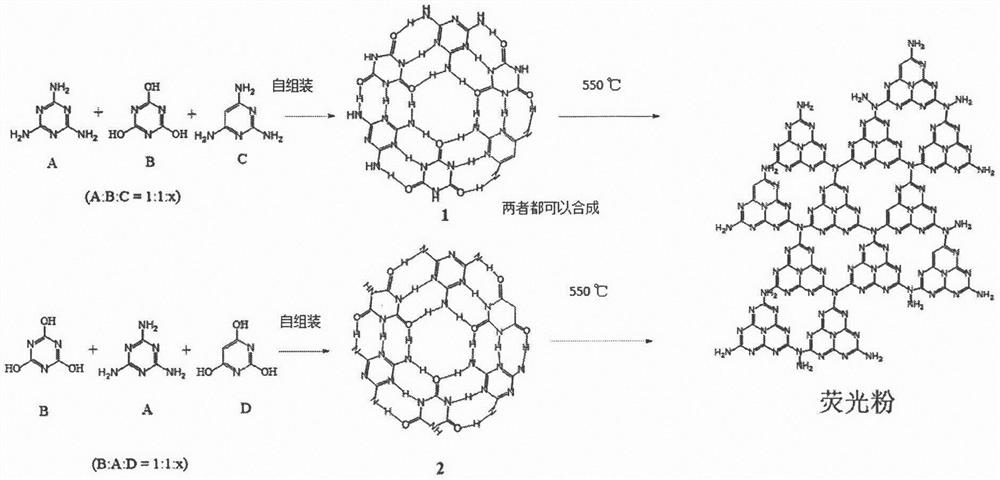

[0021] like figure 1 As shown, Embodiment 1 of the present invention includes:

[0022] Preparation process of graphitic carbon nitride phosphor with controllable emission wavelength:

[0023] (1) Preparation of graphite phase carbon nitride phosphor precursor

[0024] 1) melamine, cyanuric acid and 2,4,6-triaminopyrimidine or 0.5%, 1%, 0.5%, 1%, 5%, 10%, 20%, 30%, and 50% of barbituric acid were completely dissolved in deionized water at 60°C, respectively. The dissolved cyanuric acid was added dropwise to it, and the white precipitate of the precursor of the pyrimidine ring-coupled carazoxide ring was obtained by self-assembly through hydrogen bonds and then kept at 60°C for 24 hours. The above-mentioned precipitate was filtered with a 220nm filter process. , to obtain a white powder;

[0025] 2) Or cyanuric acid and barbituric acid are first mixed and stirred for 5 minutes, and then the completely dissolved melamine is added dropwise to it, and the pyrimidine ring-coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com