A kind of production technology of starch glue

A production process and glue technology, applied in the direction of starch-derived adhesives, adhesive types, adhesive additives, etc., can solve the problems of product quality stability damage, difficult to control the dosage, safety hazards, etc., to achieve a controllable yield , Excellent stability, high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below, so that those skilled in the art can implement it with reference to the description.

[0027] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

[0028] The realization mode of the production technique of a kind of starch glue according to the present invention, comprises the following steps:

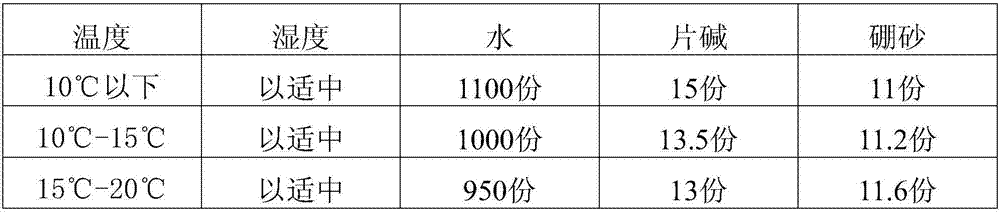

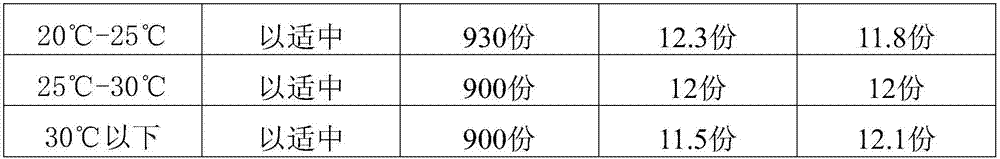

[0029] Step 1, take the following raw materials by weight for subsequent use: 850-1200 parts of water, 130-170 parts of raw starch, 2.2-3.2 parts of solid potassium permanganate, 11-16 parts of caustic soda, 10-14 parts of borax, the above Among the raw materials, potassium permanganate is selected as the oxide of starch, which is mainly used to cut off starch fibers. The role of oxidized starch prevents a large number of bubbles from being produced during production, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com