Solvent-free polyaspartate polyurea paint, and preparation method and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

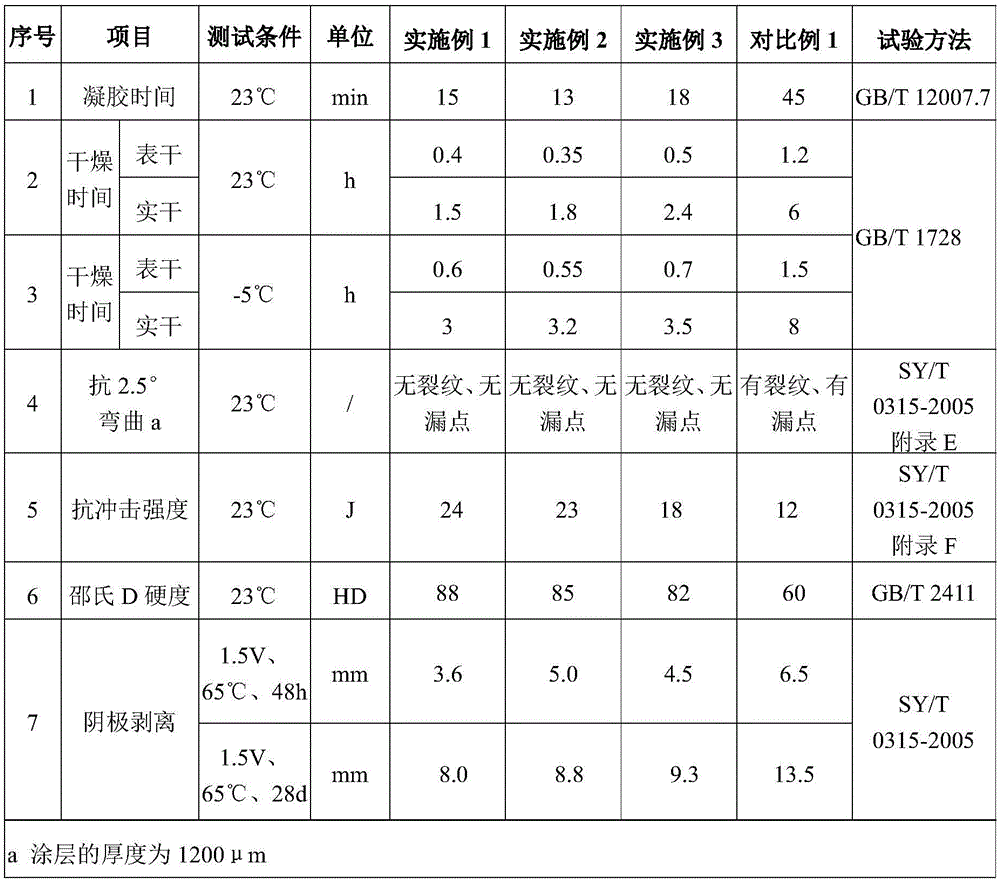

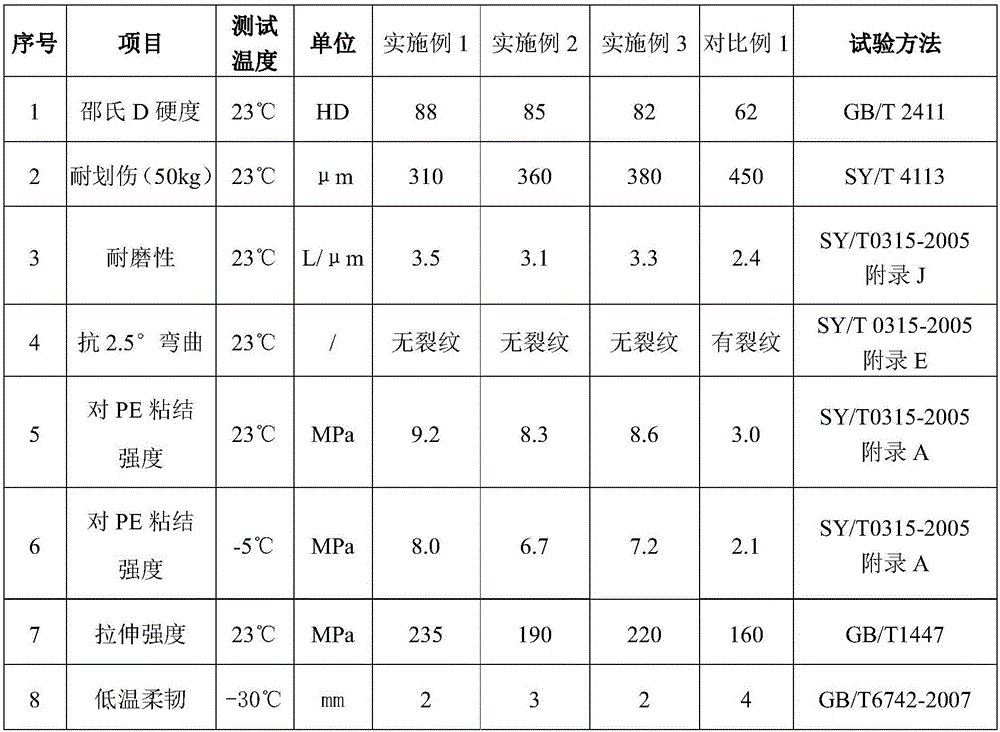

Examples

Embodiment 1

[0030] A solvent-free polyaspartic ester polyurea paint, comprising A component and B component, the components contained in the A component and their weight percentages are: 80% of HDI, 20% of modified HDI trimer. The modified HDI trimer is a polyisocyanate using isocyanate-modified methylene diisocyanate as a raw material;

[0031] The components contained in the B component and their weight percentages are: polyaspartic acid ester 70%, titanium dioxide 15%, modified silica powder 10%, defoamer 1%, leveling agent 1%, adhesion promoter 2%, coupling agent 1%.

[0032] The polyaspartic acid ester is prepared by the following steps: First, the raw materials are weighed according to the mass ratio of hexamethylenediamine (HAD) and isophoronediamine (IPDA) as 1:0.75, and the hexamethylenediamine (HAD) 1. Add isophoronediamine (IPDA) into a four-necked flask with a stirrer and a thermometer, start stirring and feed nitrogen, slowly add diethyl maleate dropwise, and keep the temper...

Embodiment 2

[0039]A solvent-free polyaspartic ester polyurea coating, including A component and B component, the components contained in the A component and their weight percentages are: HDI60%, modified HDI trimer 40%; wherein The grade of the modified HDI trimer is N3390 from Huntsman.

[0040] The components contained in the B component and their weight percentages are: polyaspartic acid ester 70%, titanium dioxide 5%, modified silica powder 15%, defoamer 2%, leveling agent 2%, adhesion promoter 3%, coupling agent 3%.

[0041] The polyaspartic acid ester is prepared by the following steps: First, the raw materials are weighed according to the mass ratio of hexamethylenediamine (HAD) and isophoronediamine (IPDA) as 1:2.5, and the hexamethylenediamine (HAD) 1. Add isophoronediamine (IPDA) into a four-necked flask with a stirrer and a thermometer, start stirring and feed nitrogen, slowly add dimethyl maleate dropwise, and keep the temperature at 40°C. The amount of dimethyl maleate is a...

Embodiment 3

[0048] A solvent-free polyaspartic ester polyurea coating, comprising A component and B component, the components contained in the A component and their weight percentages are: HDI50%, modified HDI trimer 50%; wherein The grade of the modified HDI trimer is N3390 from Huntsman.

[0049] The components contained in the B component and their weight percentages are: polyaspartic acid ester 60%, titanium dioxide 8%, modified silica powder 20%, defoamer 3%, leveling agent 3%, adhesion promoter 4%, coupling agent 2%.

[0050] The polyaspartic acid ester is prepared by the following steps: First, the raw materials are weighed according to the mass ratio of hexamethylenediamine (HAD) and isophoronediamine (IPDA) as 1:1, and the hexamethylenediamine (HAD) 1. Add isophoronediamine (IPDA) into a four-necked flask with a stirrer and a thermometer, start stirring and feed nitrogen, slowly add dibutyl maleate dropwise, and keep the temperature at 40°C. The amount of dibutyl maleate is add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com