A pressure sensor pressure assembly for satellite pipeline welding

A pressure sensor and pressure technology, applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problems of low sealing reliability, high processing requirements of parts, poor anti-vibration performance, etc., to ensure the reliability of structural strength and reduce leakage. risk, the effect of improving sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

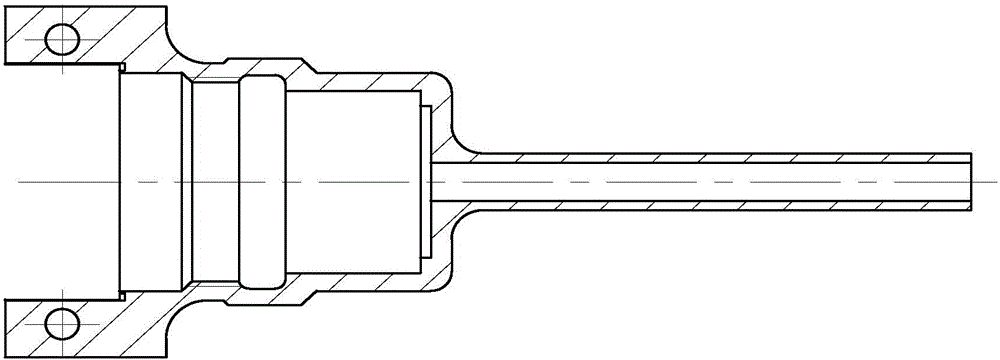

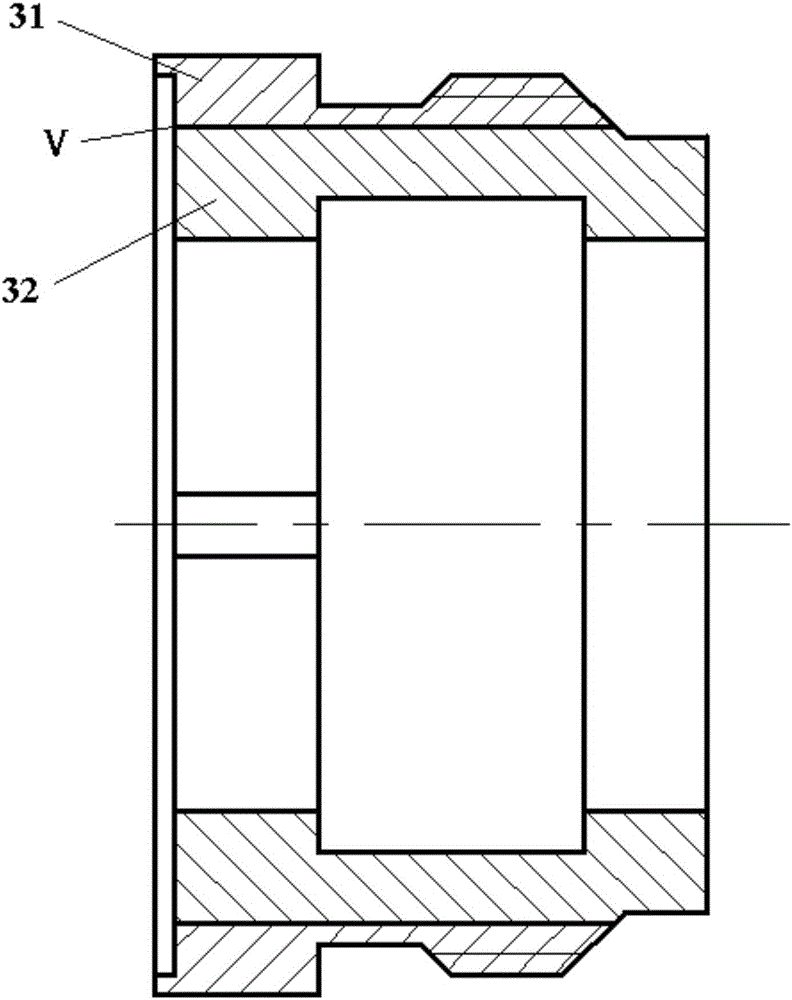

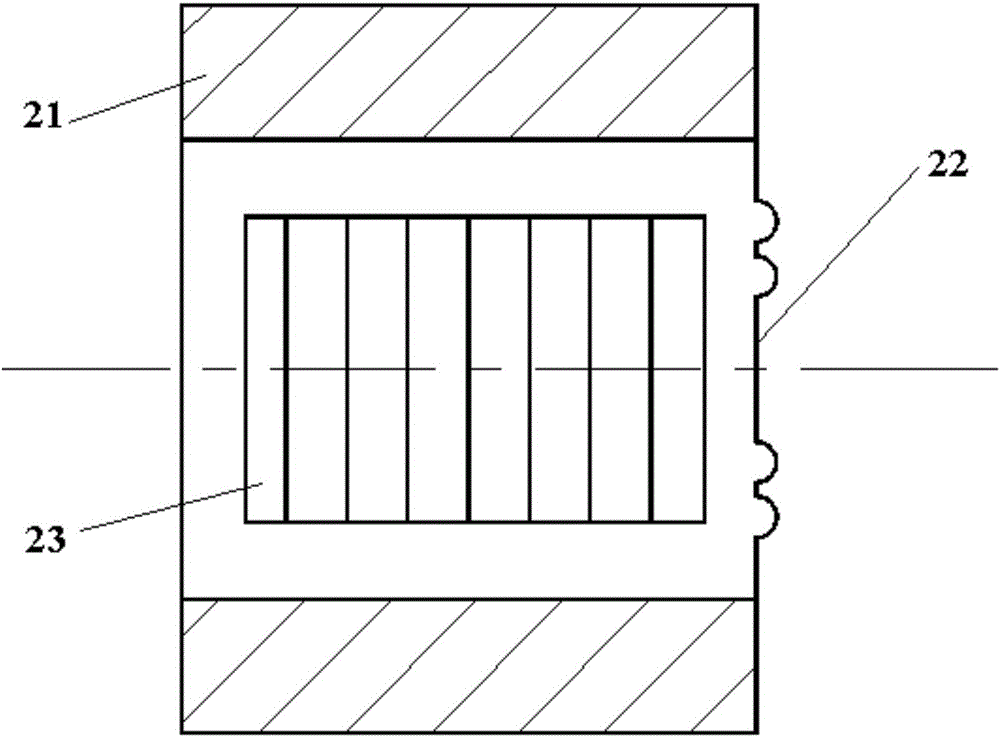

[0023] A pressure sensor pressure assembly for satellite pipeline welding, the pressure assembly is used to weld the pressure sensor and satellite pipeline, the pressure assembly includes a straight pipe pressure joint 1, a bracket 3 and a pressure sensitive element 2, such as Figure 4 shown;

[0024] Such as figure 1 As shown, the straight pipe pressure joint is made of titanium alloy and has a hollow four-step cylindrical structure, that is, the straight pipe pressure joint is four hollow cylinders from left to right, and the diameters of the adjacent cylinders become smaller in turn. There is a circular arc transition between sections; among them, from the left end, the first section of cylinder has an outer diameter of 6mm, an inner diameter of 4mm, and a length of 50mm; the second section has an outer diameter of 23mm, an inner diameter of 19.2mm, and a length of 13mm; The diameter is 26mm, the internal thread size is M22X1, and the length is 14.5mm. The fourth cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com