Air blower

A blower and preparation process technology, applied in the field of metal materials, can solve the problems of many cracks, complex aluminum alloy coping, poor elongation, etc., and achieve the effects of small expansion coefficient, strong resistance and prolonging product life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

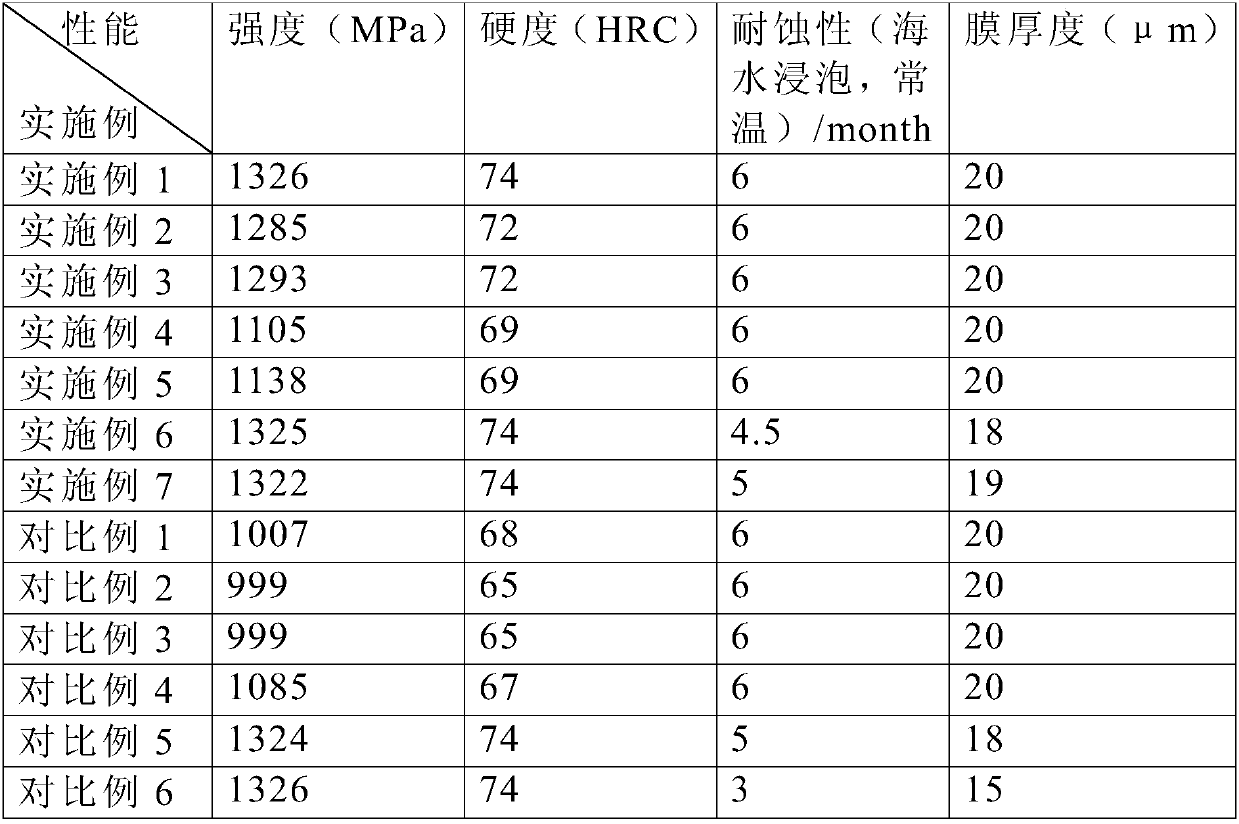

Examples

Embodiment 1

[0030] Melting: Weigh raw materials according to the composition and mass percentage of the above aluminum alloy, including Li: 1%, Pt: 0.2%, Ir: 0.2%, Ni: 3%, Mg: 1%, Cu: 3%, and the balance is Al and impurities, wherein the impurities include H<0.018%, O<0.016%, S<0.015%, N<0.02. The raw materials are put into an intermediate frequency induction furnace to be smelted into an aluminum alloy liquid and cast into an aluminum alloy plate.

[0031] Heat treatment: Heat the aluminum alloy plate to 550°C, keep it warm for 1 hour, then immerse it in water containing sodium pertechnetate for water quenching, take it out and dry it, then heat the aluminum alloy plate to 185°C, hold it for 30 minutes, then water quench it, continue Heat the aluminum alloy plate to 600°C, keep it warm for 3 minutes, then heat the aluminum alloy plate to 130°C after natural cooling, keep it warm for 25 hours, then slowly raise the temperature to 160°C, and keep it warm for 45 hours.

[0032] Forming: Th...

Embodiment 2

[0035] Melting: Weigh raw materials according to the composition and mass percentage of the above aluminum alloy, including Li: 0.5%, Pt: 0.1%, Ir: 0.1%, Ni: 2%, Mg: 0.5%, Cu: 1%, and the balance is Al and impurities, wherein the impurities include H<0.018%, O<0.016%, S<0.015%, N<0.02. The raw materials are put into an intermediate frequency induction furnace to be smelted into an aluminum alloy liquid and cast into an aluminum alloy plate.

[0036] Heat treatment: Heat the aluminum alloy plate to 550°C, keep it warm for 1 hour, then immerse it in water containing sodium pertechnetate for water quenching, take it out and dry it, then heat the aluminum alloy plate to 185°C, hold it for 30 minutes, then water quench it, continue Heat the aluminum alloy plate to 600°C, keep it warm for 3 minutes, then heat the aluminum alloy plate to 130°C after natural cooling, keep it warm for 25 hours, then slowly raise the temperature to 160°C, and keep it warm for 45 hours.

[0037] Forming...

Embodiment 4

[0045] Melting: Weigh raw materials according to the composition and mass percentage of the above aluminum alloy, including Li: 1%, Pt: 0.2%, Ir: 0.2%, Ni: 3%, Mg: 1%, Cu: 3%, and the balance is Al and impurities, wherein the impurities include H<0.018%, O<0.016%, S<0.015%, N<0.02. The raw materials are put into an intermediate frequency induction furnace to be smelted into an aluminum alloy liquid and cast into an aluminum alloy plate.

[0046] Heat treatment: heat the aluminum alloy plate to 500°C, keep it warm for 0.5h, then immerse it in water containing sodium pertechnetate for water quenching treatment, take it out and dry it, then heat the aluminum alloy plate to 170°C, hold it for 20min and then water quench it. Continue to heat the aluminum alloy plate to 500°C, keep it warm for 1min, then heat the aluminum alloy plate to 120°C after natural cooling, keep it warm for 20h, then slowly raise the temperature to 150°C, and keep it warm for 40h.

[0047] Forming: The heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com