Eutectic alloy, preparation method thereof and application of eutectic alloy as thermal barrier coating bonding layer

A eutectic alloy and alloy technology, which is applied in metal material coating process, coating, mechanical equipment, etc., can solve the problems of weak oxidation resistance, difficulty in meeting higher requirements, and insufficient thermal corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides the preparation method of the eutectic alloy described in the above technical solution, comprising the following steps:

[0048] The raw materials are mixed according to the atomic number ratio and then smelted and solidified in sequence to obtain a primary eutectic alloy;

[0049] The primary eutectic alloy is repeatedly smelted and solidified to obtain the eutectic alloy.

[0050] According to the invention, the raw materials are mixed according to the atomic number ratio and then smelted and solidified in sequence to obtain the primary eutectic alloy. In the present invention, the raw material is preferably a metal of the corresponding element, and the purity of the metal independently is preferably 99.5% or more, and more preferably 99.6 to 99.9%. In the present invention, the raw materials of each element in the AlCoCrNiPt alloy are preferably particles independently, and the particle size of the particles is preferably 2-5 mm indepe...

Embodiment 1

[0061] The aluminum particles, cobalt particles, chromium particles, nickel particles, and platinum particles with a purity of 99.9% and an average particle size of 3 mm, yttrium particles with a purity of 99.9% and an average particle size of 2 mm and hafnium wires with a purity of 99.9% were used to remove the Ionized water was used as the solvent and the power was 120W for ultrasonic cleaning for 10 minutes, and then ultrasonic cleaning was performed for 10 minutes under the condition that acetone was the solvent and the power was 120W; after drying at 80 °C for 20 minutes, it was used for later use;

[0062] Y: 0.028g (the atomic percentage of the eutectic alloy is 0.05at.%), Hf: 0.057g (the atomic percentage of the eutectic alloy is 0.05at.%), Al: l3.4 g ( The atomic percentage of AlCoCrNiPt alloy is 20 at.%), Ni: 7.5g (the atomic percentage of AlCoCrNiPt alloy is 20 at.%), Co: 7.5g (the atomic percentage of AlCoCrNiPt alloy is 20 at.%) ), Cr: 6.6g (the atomic percentage ...

Embodiment 2

[0064] The eutectic alloy was prepared according to the method of Example 1, except that the amount of raw materials was as follows: Zr: 0.06g (accounting for the atomic percentage of the eutectic alloy: 0.1 at.%), Hf: 0.47g (accounting for the total The atomic percentage of the crystalline alloy is 0.4 at.%), Al: 4.1g (the atomic percentage of the AlCoCrNiPt alloy is 23 at.%), Ni: 6.6g (the atomic percentage of the AlCoCrNiPt alloy is 17 at.%) ), Co: 7.0g (18 at.% in AlCoCrNiPt alloy), Cr: 7.9g (23 at.% in AlCoCrNiPt alloy), Pt: 24.4g (18 at.% in AlCoCrNiPt alloy) The percentage is 19 at.%).

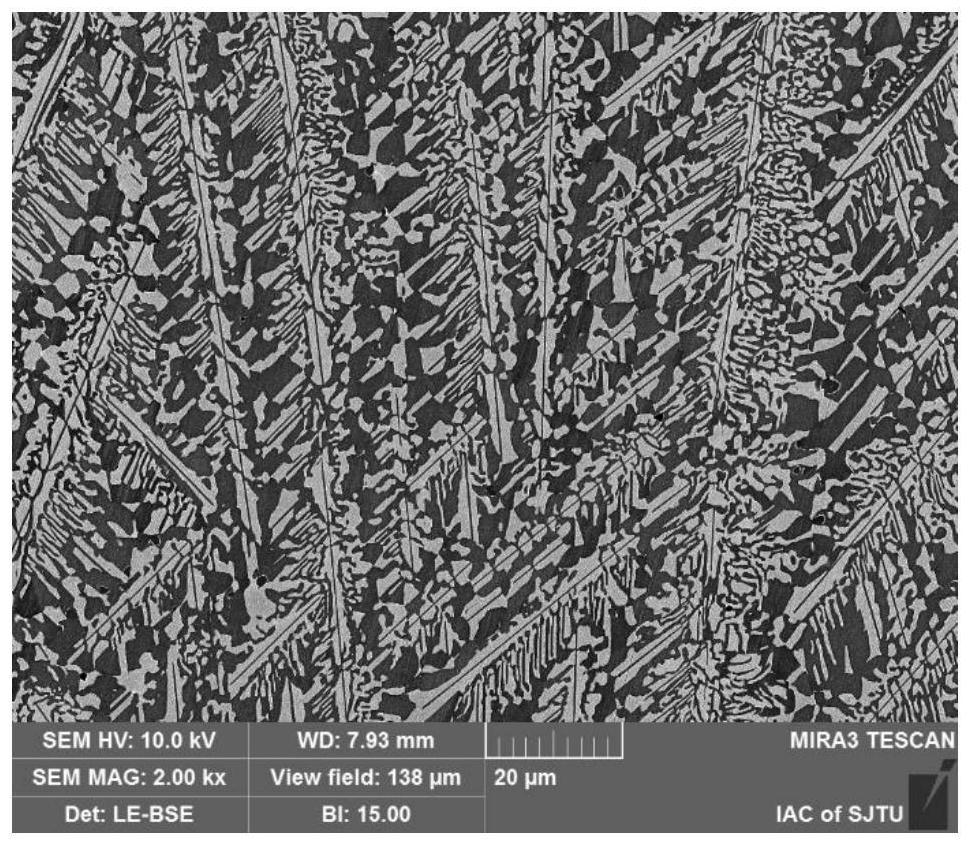

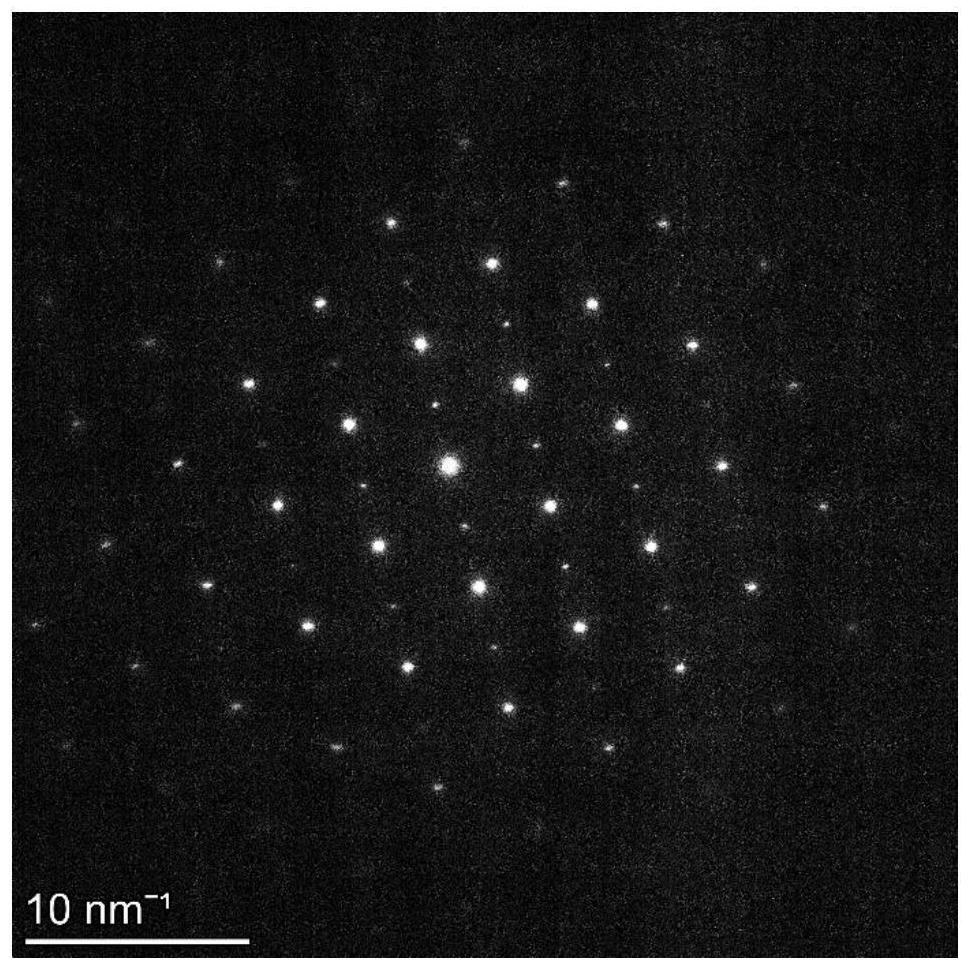

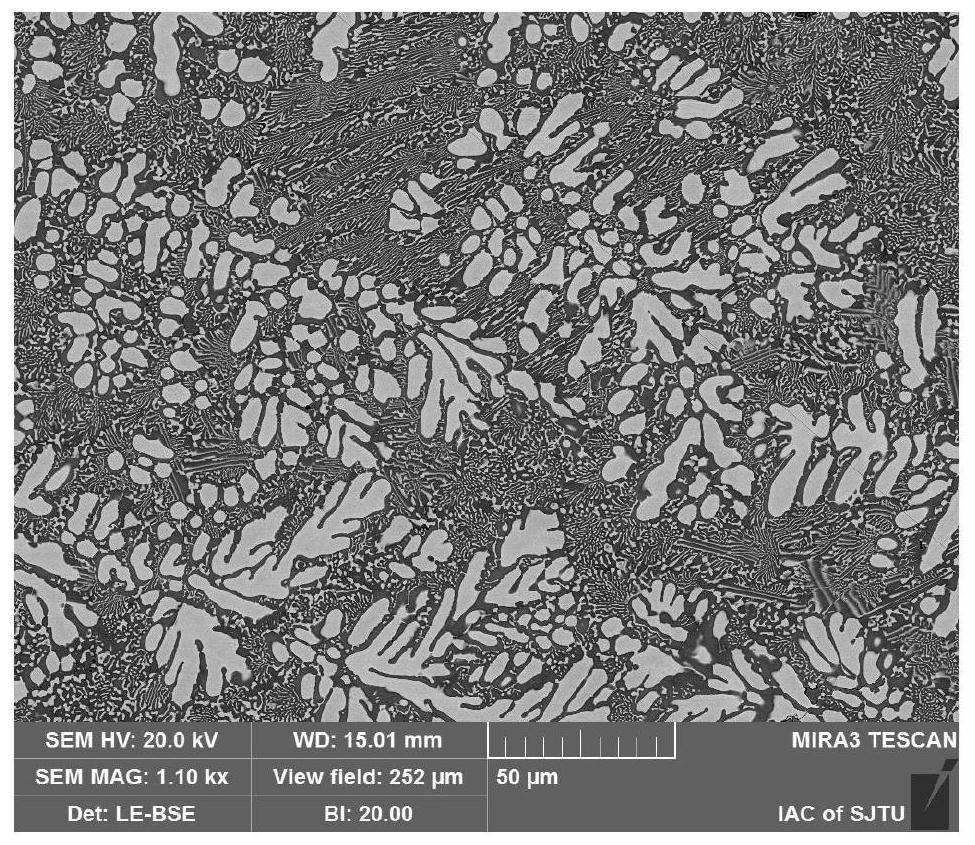

[0065] After the eutectic alloy prepared in Example 1 was longitudinally cut, metallographically prepared and polished, the microstructure and structure were analyzed by scanning and transmission electron microscopes, and the scanning electron microscope backscattered electron diagram was obtained, as shown in the following figure. figure 1 shown. Depend on figure 1 It can be seen th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com