Melted CMAS-corrosion resistant rare-earth aluminate thermal barrier coating and preparation method thereof

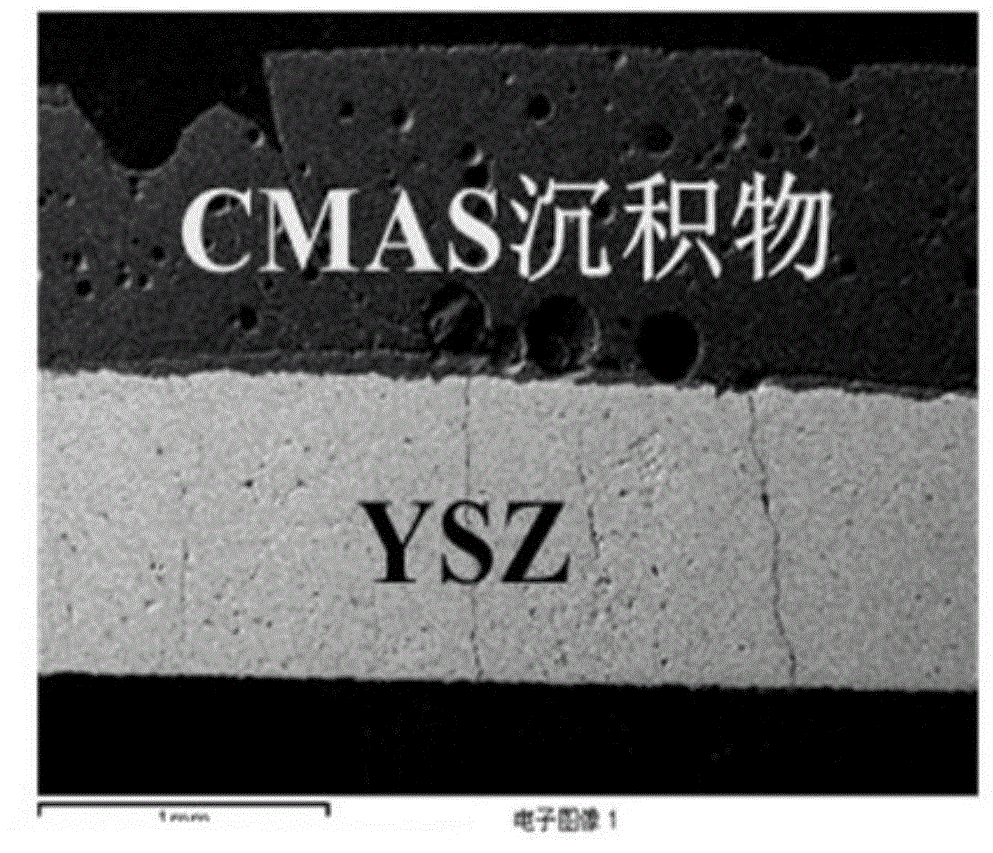

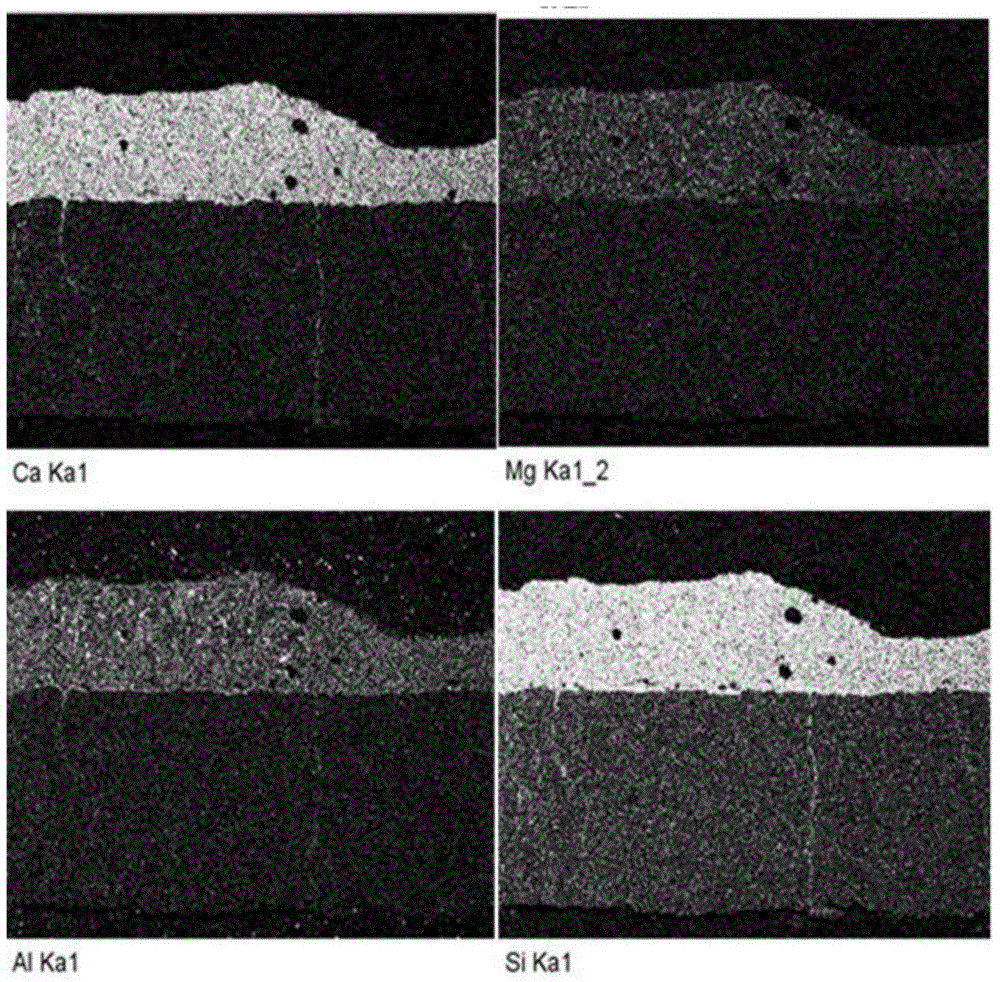

A technology of thermal barrier coating and aluminate, which is applied in the direction of coating, fusion spraying, metal material coating process, etc., can solve the problems of melting CMAS corrosion of YSZ thermal barrier coating, and achieve excellent resistance to melting CMAS corrosion , low oxygen transmission rate, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a preparation method of a rare earth aluminate thermal barrier coating resistant to molten CMAS corrosion, comprising the following steps:

[0044] The first step is to pre-treat the surface of the substrate by sandblasting. The superalloy substrates are polished with 200#, 400#, and 600# sandpaper respectively, placed in acetone for ultrasonic cleaning for more than 15 minutes, and then the surface is pretreated by sandblasting for standby. The high-temperature alloy is selected from K3 high-temperature alloy.

[0045] The second step is to prepare NiAlDy, NiCoCrAlY or NiAlPt bonding layer on the substrate;

[0046] (A) adopt atmospheric plasma spraying method to prepare NiAlDy or NiCoCrAlY bonding layer;

[0047] Atmospheric plasma spraying method is used to prepare the bonding layer on the surface of the pretreated sample. The main process parameters are: the current is 550-700A, the voltage is 50-70V, the powder feeding rate is 10-20g / min, a...

Embodiment 1

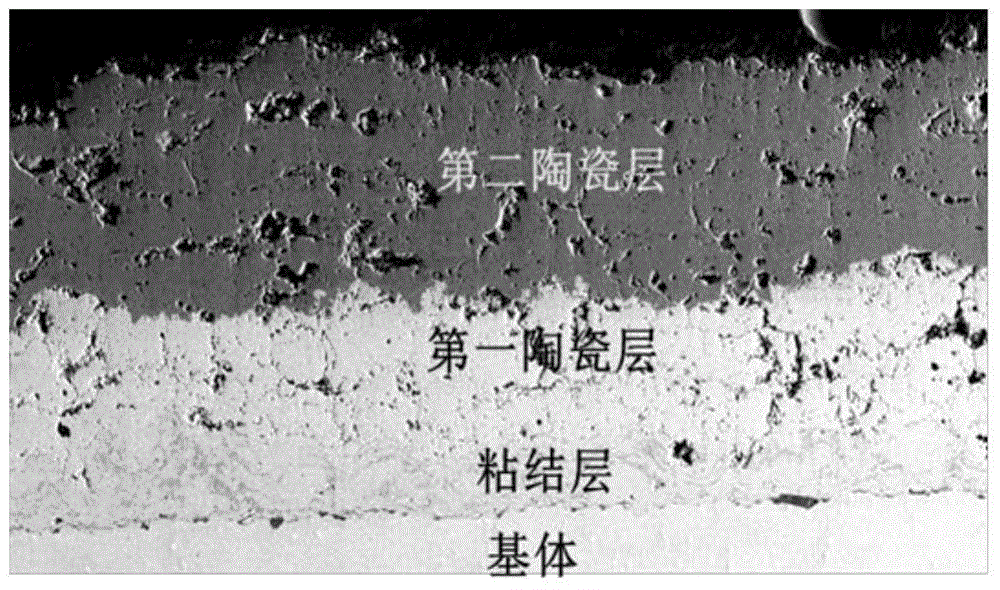

[0070] Embodiment 1: prepare Y on the superalloy substrate surface 3 al 5 o 12 / YSZ double ceramic layer thermal barrier coating, the specific steps are as follows:

[0071] The first step is to prepare the substrate. The surface of the superalloy base material was polished with 200#, 400#, and 600# sandpaper respectively, put in acetone and ultrasonically cleaned for 15 minutes, and then the surface was pretreated by sandblasting for standby.

[0072] In the second step, a NiCoCrAlY bonding layer is prepared on the substrate;

[0073] Atmospheric plasma spraying method is used to prepare the bonding layer on the surface of the pretreated sample. The main process parameters are: the current is 650A, the voltage is 70V, the powder feeding rate is 15g / min, the spraying distance is 120mm, and the main gas flow Ar gas is 2200L / h, h 2 The air flow is 7L / min. The deposition time was 20 min, and a NiCoCrAlY bonding layer with a thickness of 90 μm was obtained.

[0074] After ...

Embodiment 2

[0080] Embodiment 2: YAlO is prepared on the surface of superalloy substrate 3 / YSZ double ceramic layer thermal barrier coating.

[0081] The material of the second ceramic layer is selected as YAlO 3 , all the other steps are with embodiment 1, make YAlO 3 / YSZ double ceramic layer thermal barrier coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com