Large-sized precision bearing radial play multifunctional automatic measurement method and measuring apparatus

A technology of radial clearance and automatic measurement, applied in mechanical bearing testing, measuring devices, instruments, etc., can solve problems such as easy error, large subjective error, troublesome operation, etc., to improve accuracy and reliability, eliminate measurement effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

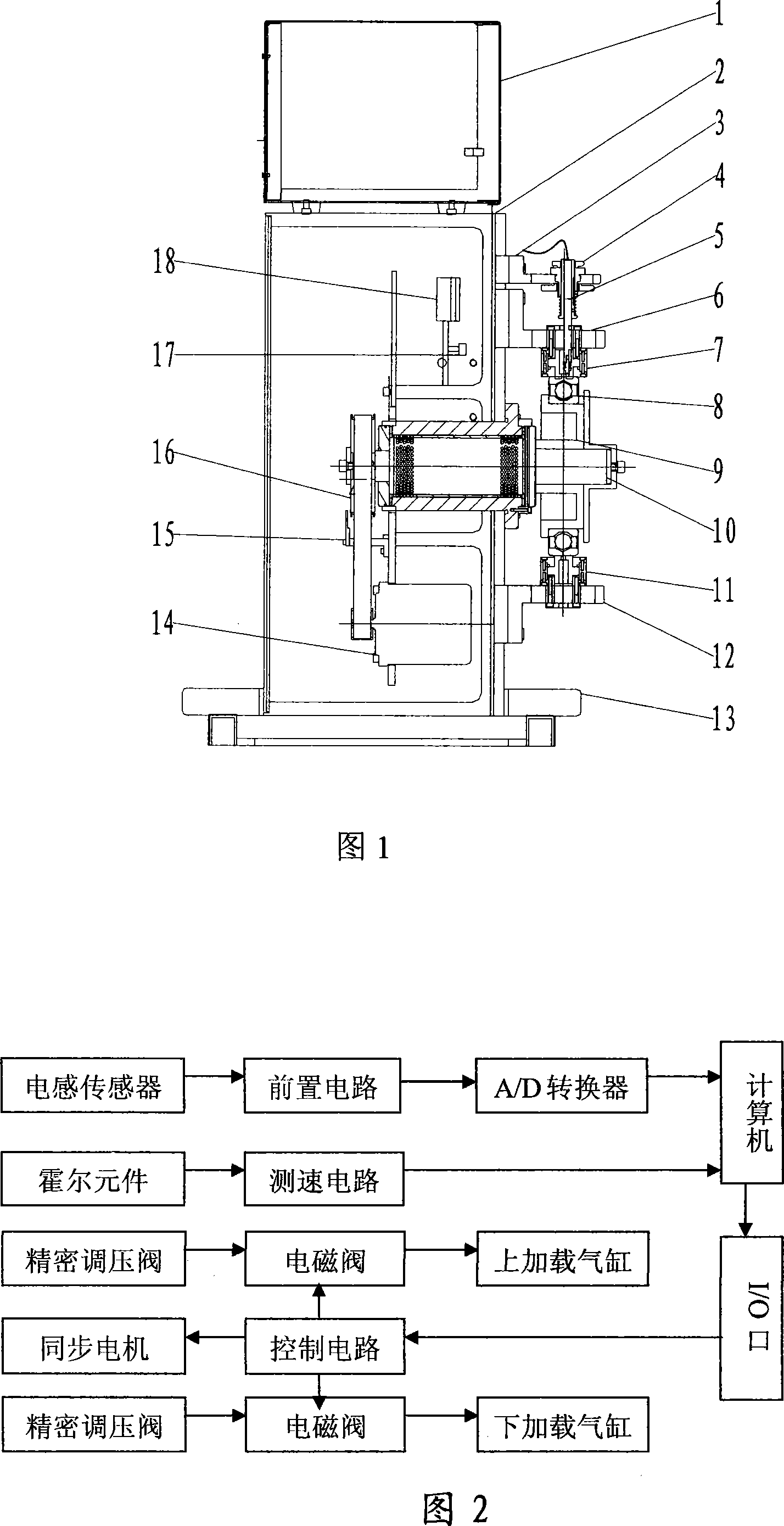

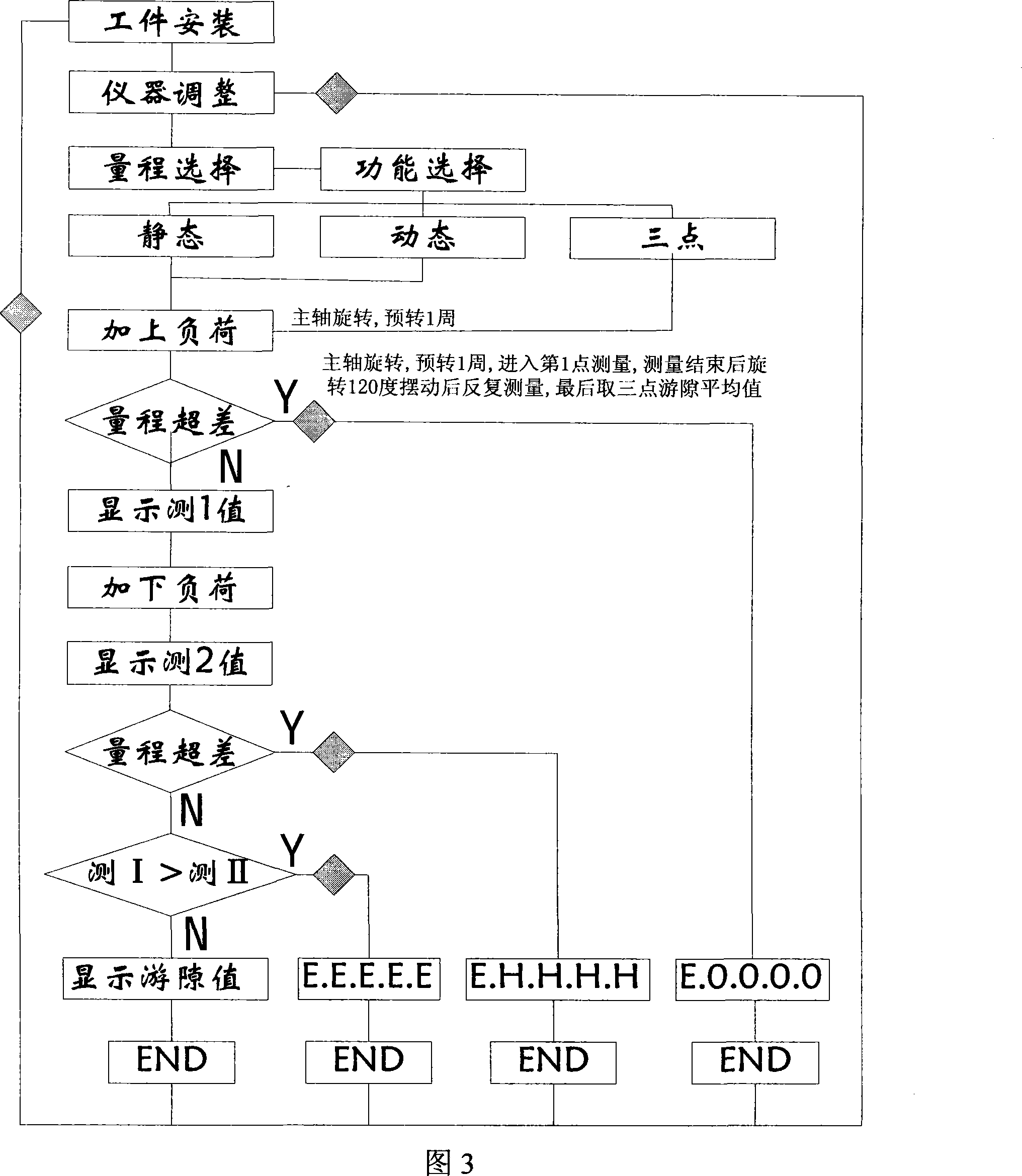

[0034] As shown in Figure 1: the tested bearing (8) is installed on the measuring mandrel (9), and the loading heads of the upper and lower loading cylinders (7) and (11) respectively act on the middle of the upper and lower sides of the outer ring of the tested bearing (8) (keep a certain gap), the measuring head of the inductance sensor (5) acts on the upper middle of the outer ring of the tested bearing (8); the synchronous motor (14) drives the measuring spindle (10) to rotate through the pulley and the toothed belt (16) , and then drive the measuring mandrel (9) to rotate, and the inner ring of the tested bearing (8) installed on the measuring mandrel rotates at the same speed. The upper and lower loading cylinders (7) and (11) respectively apply upper and lower loads to the outer ring of the tested bearing (8). The circuit performs rhythm control through solenoid valves. At the same time, the control circuit can control the rotation or stop of the synchronous motor (14)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com