Heat-not-burn cigarette sheet prepared by fermentation

A heat-not-burn, cigarette technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of cigarette sheet strength, toughness and smoking agent load capacity cannot meet the needs, etc., to promote uniform suspension, enhance sheet strength, The effect of ensuring process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A heat-not-burn cigarette sheet prepared by fermentation, comprising the following steps:

[0026] 1) The tobacco fermentation culture was sterilized at 120°C for 10 minutes, and inoculated with 6% of the total weight of Gluconacetobacter xylinum; the tobacco fermentation medium was a mixture of 80-mesh tobacco powder and tobacco fiber with a mass ratio of 70:30, and in the medium Water 90%.

[0027] 2) dynamically fermenting the inoculated tobacco fermentation medium at 30° C. and 120 r / min for 5 days;

[0028] 3) After fermentation, concentrate by rotary steaming at 70°C to make the water content 40%;

[0029] 4) Add 25% glycerol by weight of the slurry, 3% tobacco extract with a mass ratio of 80:20, and orange extract, mix evenly, and stir at a high speed of 500 r / min to prepare a slurry;

[0030] 5) Spread the slurry on a 120-mesh nylon net, roll it evenly, and dry it at 90°C until the water content is 8% and the thickness is 0.2mm.

Embodiment 2

[0032] A heat-not-burn cigarette sheet prepared by fermentation, comprising the following steps:

[0033] 1) Tobacco fermentation culture was sterilized at 120°C for 10 minutes, and inoculated with 4% of the total weight of Gluconacetobacter xylinum; the tobacco fermentation medium was a mixture of 160-mesh smoke powder and tobacco fiber with a mass ratio of 90:10, and in the culture medium Water 90%.

[0034] 2) dynamically fermenting the inoculated tobacco fermentation medium at 30° C. and 140 r / min for 6 days;

[0035] 3) After fermentation, concentrate by rotary steaming at 70°C to make the water content 50%;

[0036] 4) Add glycerol and propylene glycol with a mass ratio of 3:1, 4% of tobacco extract and phenylethanol at a mass ratio of 90:10, accounting for 40% by weight of the slurry, mix evenly, and stir at a high speed of 700r / min , to prepare slurry;

[0037] 5) Spread the slurry on silicone oil paper, roll it evenly, and dry it at 80°C until the water content is ...

Embodiment 3

[0039] A heat-not-burn cigarette sheet prepared by fermentation, comprising the following steps:

[0040] 1) Tobacco fermentation culture was sterilized at 120° C. for 10 minutes, inoculated with Acetobacter xylinum accounting for 10% of the total weight; the tobacco fermentation medium was a 120-mesh tobacco powder and tobacco fiber mass ratio of 80:20 water mixture, and the water in the medium was 80%.

[0041] 2) dynamically fermenting the inoculated tobacco fermentation medium at 30° C. and 120 r / min for 5 days;

[0042] 3) After fermentation, concentrate by rotary steaming at 70°C to make the water content 40%;

[0043] 4) Adding 25% glycerol by weight of the slurry, 3% tobacco extract and orange extract with a mass ratio of 80:20, mixing evenly, and stirring at a high speed of 1000r / min to prepare a slurry;

[0044] 5) Spread the slurry on a 160-mesh nylon net, roll it evenly, and dry it at 110°C until the moisture is 10% and the thickness is 0.2mm.

PUM

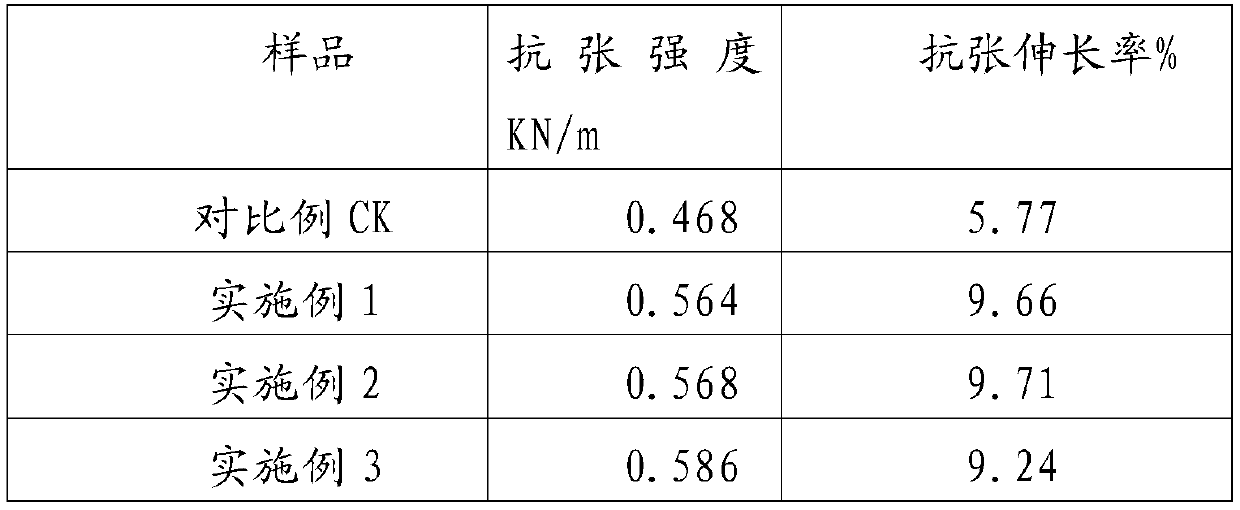

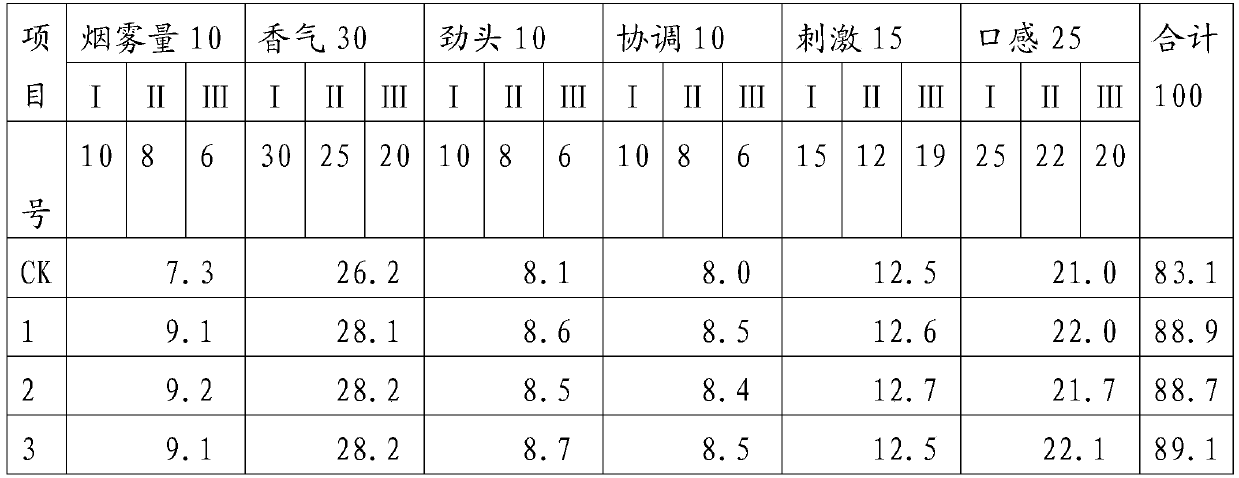

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com