Preparation method of novel electric spark working solution

A technology of EDM and working fluid, which is applied in the field of preparation of new EDM working fluid, can solve the problems of large loss of tool electrodes and achieve the effects of small tool electrode loss, safe use, and reduced electrode loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A preparation method of a novel electric discharge working fluid, comprising the following steps:

[0027] (1) According to the volume ratio V 粉末 / V 煤油 =(0~0.9) Add the powder into kerosene and stir to make it evenly distributed;

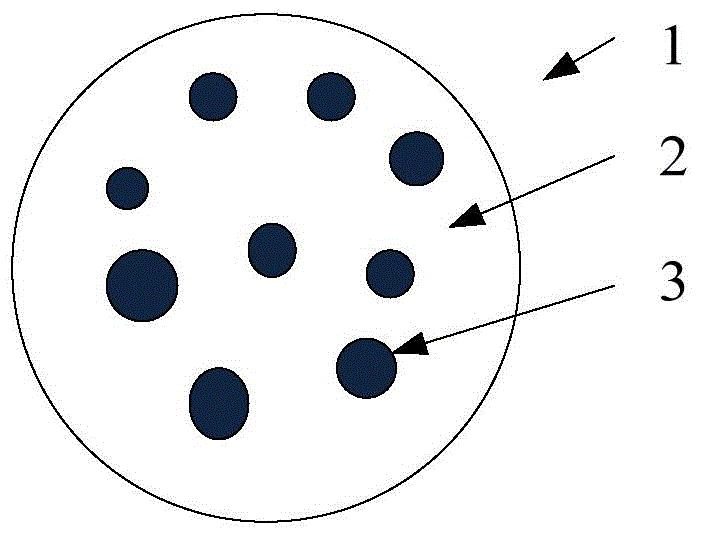

[0028] (2) The kerosene that the above-mentioned preparation is mixed with powder is added into an appropriate amount of deionized water, and stirred to obtain an emulsion, which is the required novel electrical discharge machining fluid of the present invention (such as figure 1 shown). Including base liquid deionized water 1, kerosene droplets 2 suspended in deionized water, powder particles 3 distributed in kerosene;

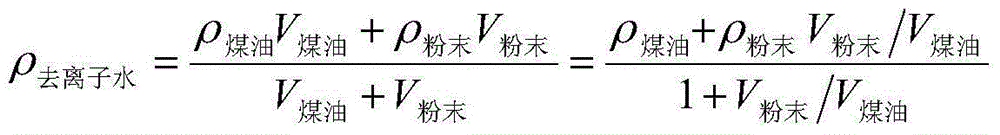

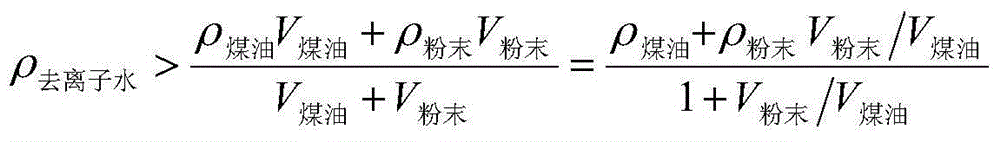

[0029] 1. If the volume ratio of powder to kerosene conforms to the following formula:

[0030]

[0031] The average density of the suspension composed of kerosene and powder is the same as that of deionized water, and it can be suspended in deionized water stably and evenly; under the action of water tension, the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com