Tobacco composite suitable for being added to dry-method recycled tobacco coating liquid and application of composite for preparing heating non-burning cigarettes

A technology for reconstituted tobacco leaves and compositions, applied in the field of preparing heat-not-burn cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

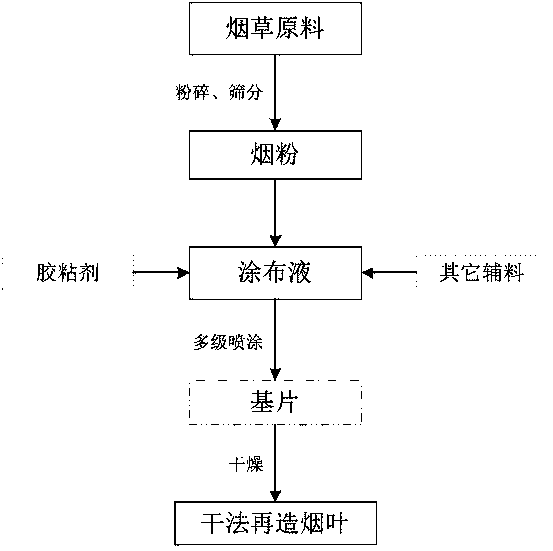

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Optimization experiment of low-temperature cigarette raw materials

[0032] Through a lot of research, the present invention concludes that the dry-process reconstituted tobacco leaf has relatively good application effect in the production of heat-not-burn cigarettes. In order to verify this conclusion, a lot of experiments are done for comparison. The following three types of raw materials, natural tobacco leaves, paper-making reconstituted tobacco leaves, and dry-process reconstituted tobacco leaves, are used in low-temperature cigarettes to investigate their application in low-temperature cigarettes and verify the raw material design idea of the present invention.

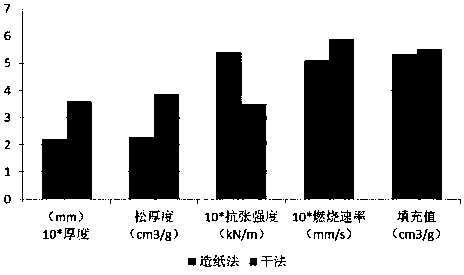

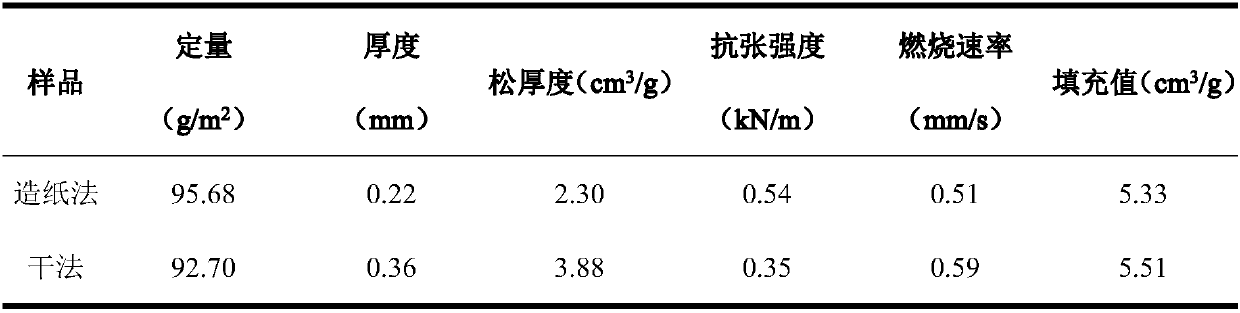

[0033] 1. Research on physical and chemical indicators of raw materials: testing of physical and chemical indicators of three raw materials, among which, quantitative determination refers to GB / T 451.2-2002; thickness measurement refers to GB / T 451.3-2002; tensile strength measurement refers to...

Embodiment 2

[0069]Although using dry reconstituted tobacco leaves as the raw material of heat-not-burn cigarettes has more advantages than papermaking reconstituted tobacco leaves, due to the change of heating temperature and the difference between burning and non-burning conditions, the reconstituted tobacco leaves prepared according to the existing conventional dry method are used as After the core material is prepared, the heat-not-burn cigarette has a certain deficiency in eating and smoking. In order to improve the overall quality, this embodiment provides a leaf group raw material, which is obtained by comminuting and pulverizing the following 9 kinds of tobacco leaf raw materials according to the number of parts by mass:

[0070] (1) 20 pieces of tobacco leaf fragments, the nicotine content is 1.83%, the total sugar content is 10.53%, the total nitrogen content is 2.17%, the potassium content is 3.15%, the chlorine content is 0.40%, the ash content is 14.48%, and the nitrate content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com