Method and device for simulating process of burning cigarette to generate smoke

A technology for smoke and cigarettes, which is applied in the field of simulating the combustion of cigarettes to generate smoke, can solve the problems of low content of cigarette smoke components, difficulty in accurate determination by conventional methods, and complex sample bodies, and achieves the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

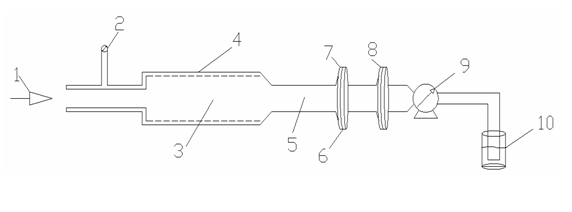

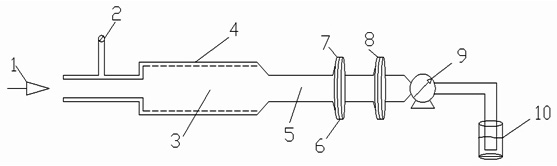

[0015] The device for simulating smoke generated by cigarette combustion is composed of a heating device 4, two sets of traps 7, 8, a suction pump 9, and an exhaust gas trapping device 10. The tail 5 of the heating device 4 is connected to two sets of traps 7, 8. The catcher 8 is connected to the suction pump 9, the suction pump 9 is connected to the exhaust gas collection device 10, the other end of the heating device is connected to the gas source 1, and a gas flow meter 2 is connected, and put in the two catchers Cambridge filter 6.

[0016] Put the shredded tobacco sample into the sample placement place 3 in the heating device, feed the air flow, adjust the air intake through the flow meter 2, the atmospheric pressure at the gas flow meter is limited to 90kPa, adjust the air intake and air intake with the suction pump 9 The exhaust volume is balanced, and the air flow rate is 900mL / min; then, infrared heating is carried out on the heating device to burn the sample. Heat f...

Embodiment 2

[0018] The device for simulating the smoke generated by cigarette combustion is the same as in Example 1. Add 0.1 g of the glucose sample evenly on the quartz wool and place it at 3 places where the sample is placed. , Atmospheric pressure at the gas flowmeter is limited to 100kPa, use a suction pump to adjust the balance of gas intake and exhaust volume, the flow rate is 1000mL / min, conduct infrared heating on the heating device to burn the sample, and the heating temperature is 400 ℃ ~ 800 °C, the time used is 50 sec, and then from 800 °C to 400 °C, the time used is 1 min, until the glucose sample is burned out. The captured Cambridge filter is tested and analyzed according to the requirements according to the standard detection method, so as to obtain the content of the target substance to be investigated during the combustion process of glucose.

Embodiment 3

[0020] The device for generating flue gas by imitating cigarette combustion is the same as in Example 1. Add potassium nitrate to the cut tobacco sample by 3% of the cut tobacco sample mass, then weigh 0.7g and place it at 3 places where the sample is placed, and inject a nitrogen-oxygen mixture ( o 2 :N 2 =9:91), the atmospheric pressure at the gas flowmeter is limited to 90kPa, use a suction pump to adjust the gas intake and exhaust volume balance, the flow rate is 1050mL / min, conduct infrared heating on the heating device to burn the sample, and raise the heating temperature From 400°C to 800°C, the time used is 50 sec, and then from 800°C to 400°C, the time used is 1 min, which can be circulated until the sample is burned out. The captured Cambridge filter is tested and analyzed according to the requirements according to the standard detection method, so as to obtain the content of the target substance to be investigated produced during the combustion process of the shred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com