Heating-non-burning cigarette fuming granular material and preparation method thereof

A heat-not-burn and smoke-generating particle technology, which is applied in tobacco, tobacco treatment, application, etc., can solve the problems of single process, limit the development and progress of heat-not-burn cigarettes, and high energy consumption, and achieve the effect of solving a single type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

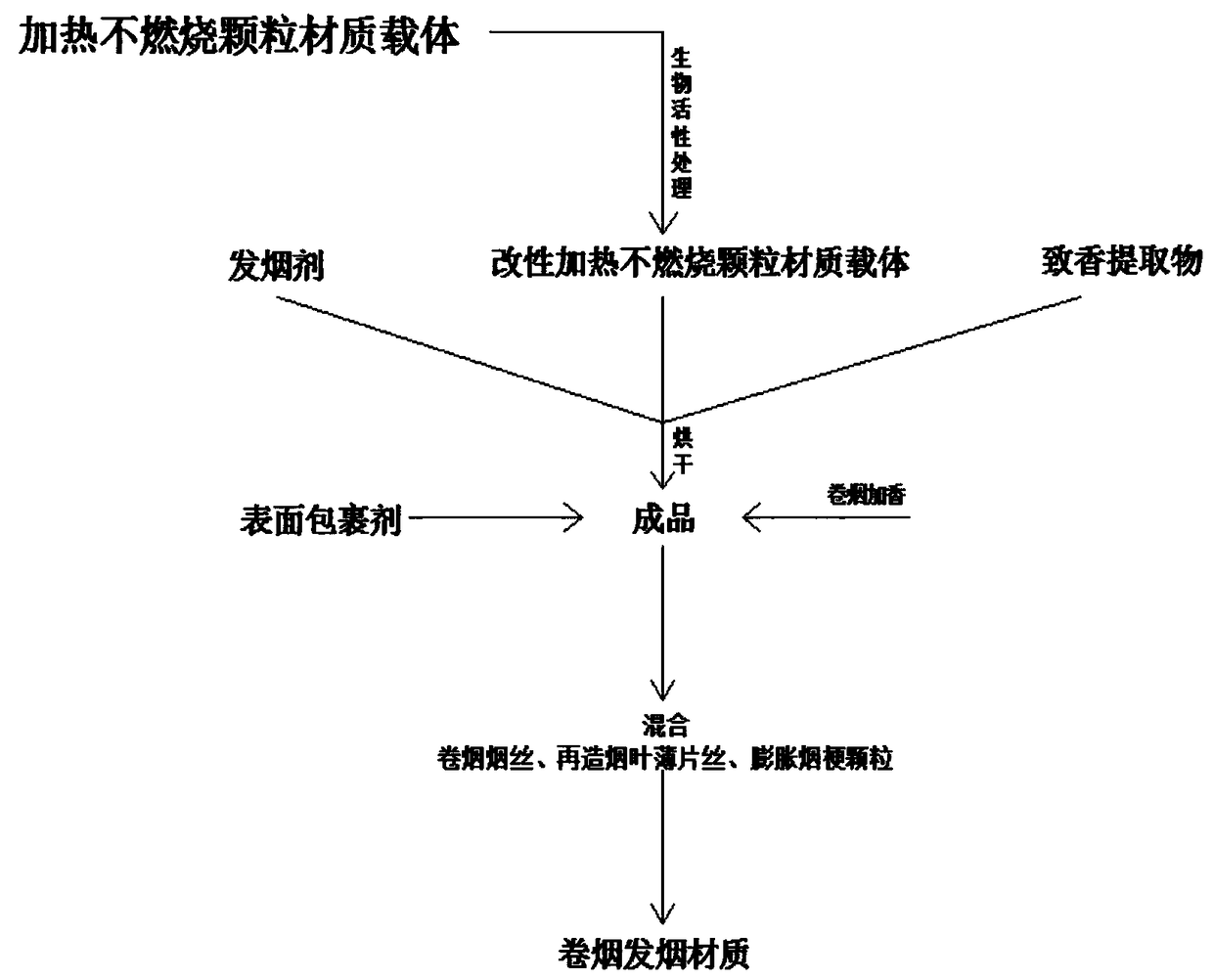

[0020] Reference figure 1 , A method for preparing heat-not-burn cigarette smoking particles, including the following steps:

[0021] S1: To prepare the heat-not-burn cigarette smoking particle material, first select the heat-not-burn particle material carrier, wherein the carrier is preferably domestic high-quality particles or natural, mineral, synthetic particles and their powders for granulation or compounding, and biologically active treatment Then mix it with the aroma extract and smoke agent;

[0022] S2: After being fully absorbed in a ventilated and sterile environment, it is sent to a special oven to bake for 0.2-2h. After the moisture content is qualified, the blended fragrance components will be prepared;

[0023] S3: Add the cigarette flavoring method to the particles, and finally add the surface wrapper, stir evenly to obtain the finished product, which can be mixed with cigarette tobacco, reconstituted tobacco leaf flakes, expanded tobacco stem particles and other mat...

Embodiment 1

[0026] It is preferred that domestic natural granular rush grass and gramineous plant granules are compounded in proportion as a carrier, treated with protease preparation, and then mixed with the formulated smoke agent and aroma extract according to the proportion, and then in a ventilated, sterile environment Let stand for 12-24h, stirring every 1-2h during the period, so that the material liquid is more fully absorbed by the particle carrier, and send the mixed particles into a special oven, drying temperature is 80℃, time 60min, during the drying process Stir at an interval of 30 minutes to make it evenly heated. After passing the moisture test, the mixed particles are added in the way of cigarette flavoring according to the prepared aroma components, and then absorbed after 0.5-2h. Finally, the surface wrapper is added and mixed evenly to obtain the finished product.

Embodiment 2

[0028] Preferably, diatom mud powder, tobacco powder, and β cyclodextrin are proportioned, and the formulated smoke agent and aroma extract are mixed uniformly in proportion, and the smoke particles are prepared by extrusion spheronization granulation. The prepared smoke particles are sent to a special oven, the drying temperature is 70°C, the time is 90 minutes, and the stirring is performed at intervals of 30 minutes during the drying process to make it evenly heated. After the water content is qualified, the mixed particles are added in the way of cigarette flavoring according to the formulated aroma components, and then absorbed for 0.5-2h to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com