Preparation method of compound air purification agent

A technology of air purifier and modifier, which is applied in the field of preparation of composite air purifiers, which can solve the problems of inability to judge purifiers intuitively, unfavorable adsorption capacity, and high environmental protection pressure, and achieve superior performance, low manufacturing cost, and resource conservation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

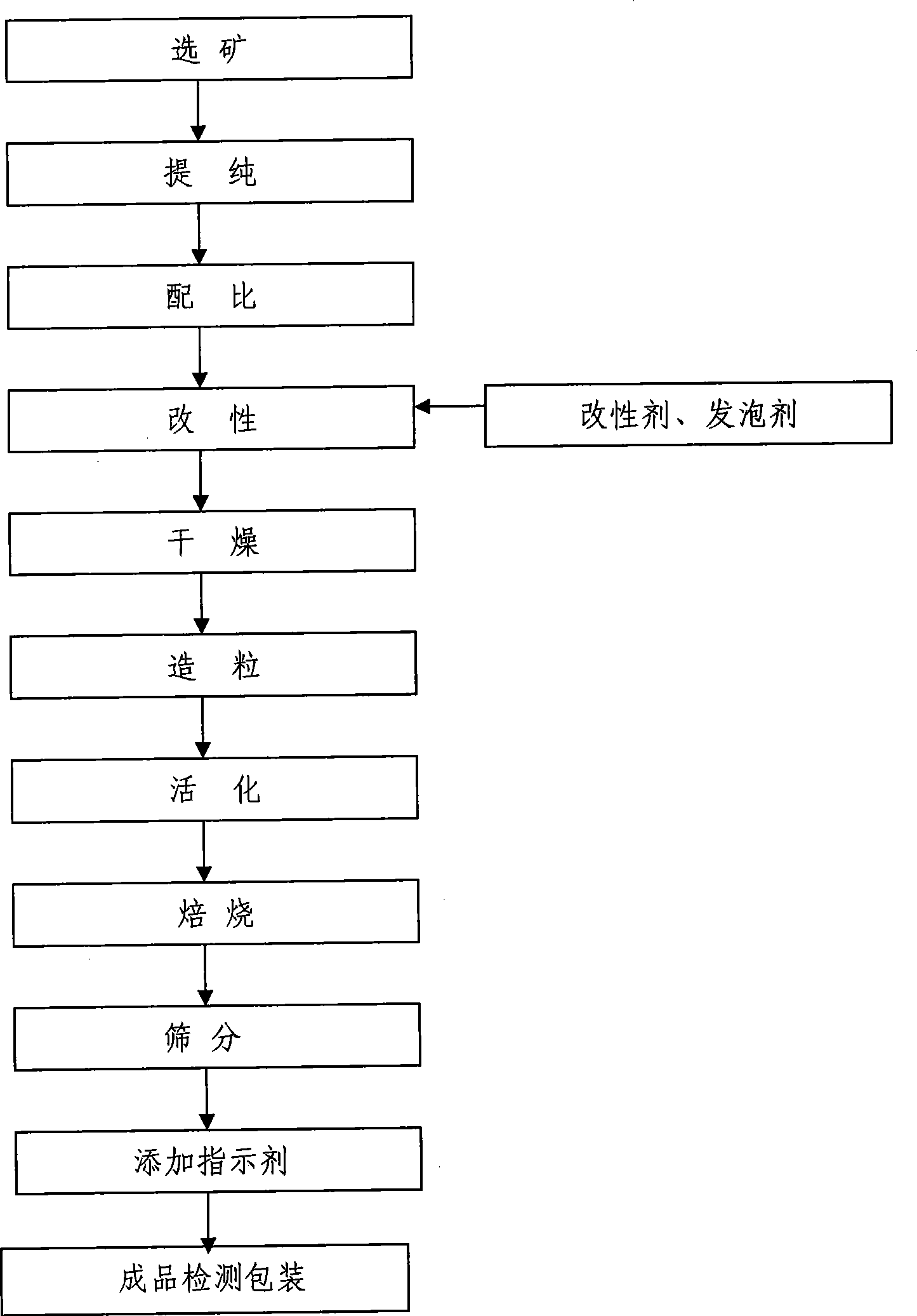

Image

Examples

Embodiment 1

[0021] (1) Mineral dressing: choose zeolite, diatomite, montmorillonite and sepiolite, four kinds of pure natural mineral material concentrates with adsorption capacity, the content of which is more than 60%;

[0022] (2) Purification: the four kinds of mineral materials selected are purified respectively;

[0023] (3) Proportioning: Proportioning and mixing the four purified mineral materials, the weight ratio is 10% to 40% of zeolite, 5% to 20% of diatomite, 20% to 60% of montmorillonite, sea foam Stone 10% to 40%;

[0024] Modification: The modifying agent is sodium carbonate or sodium chloride or sodium fluoride or sodium bisulfite, and its consumption is 1% to 10% of the total weight of the mineral material after purification and proportioning. The foaming agent is ammonium bicarbonate or sodium bicarbonate, and its consumption is 1% to 10% of the total weight of the purified mineral material. According to the appropriate proportion of the weight of the mineral material...

Embodiment 2

[0034] (1) Mineral dressing: choose zeolite, retortite, sepiolite and attapulgite, four kinds of pure natural mineral material concentrates with adsorption capacity, the content of which is more than 60%;

[0035] (2) Purification: the four kinds of mineral materials selected are purified respectively;

[0036] (3) Proportioning: Proportioning and mixing the four purified mineral materials, the weight ratio is 10% to 40% of zeolite, 5% to 15% of rectorite, 20% to 40% of sepiolite, attapulgite Soil 20% to 40%;

[0037] (4) Modification: the modifying agent is sodium carbonate or sodium chloride or sodium fluoride or sodium bisulfite, and its consumption is 1% to 10% of the total weight of the mineral material after purification and proportioning. The foaming agent is ammonium bicarbonate or sodium bicarbonate, and its consumption is 1% to 10% of the total weight of the purified mineral material. According to the appropriate proportion of the weight of the mineral material aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com