Cellulose diacetate composite shape-stabilized phase-change material, and preparation method and application thereof

A technology of cellulose diacetate and phase change material, applied in the application, heat exchange materials, chemical instruments and methods, etc., can solve the problems of unspecified cooling effect, unspecified cigarette diameter and suction resistance, etc. Excellent solid-solid phase transition, excellent thermal stability, and the effect of reducing flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

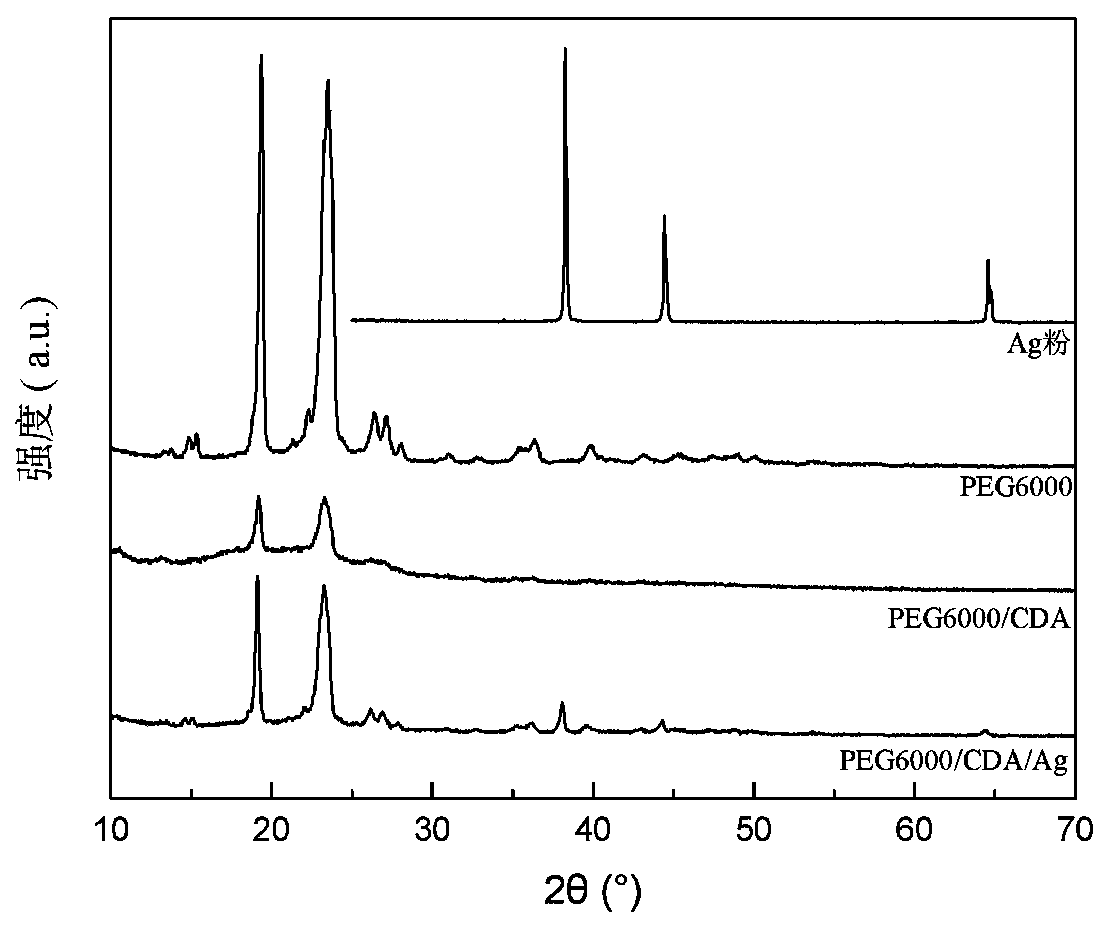

[0032] The preparation method of described cellulose diacetate composite shaping phase change material, comprises the following steps:

[0033] (1) Use the solvent blending method to prepare CDA acetone solution and PEG acetone solution with equal mass fractions. The specific operation is as follows: at room temperature, dissolve cellulose diacetate (CDA) in acetone solution and place it on a shaker for 1 hour; 40°C Next, dissolve polyethylene glycol (PEG) in acetone solution, and stir in a water bath for 1 h;

[0034] (2) Slowly add a certain mass of CDA acetone solution dropwise into the PEG acetone solution, stir rapidly for 10 minutes, then add a certain mass of metal powder and stir in a sealed water bath at 40°C for 6 hours;

[0035] (3) After stirring, transfer the mixed solution to a petri dish and put it in a fume hood to air dry, and then put it in an oven at 50°C for 12 hours;

[0036] (4) Grinding, tableting, and sieving the prepared material to obtain cellulose d...

specific Embodiment 1P

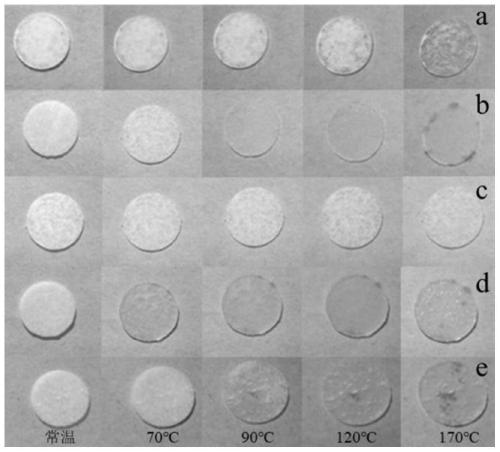

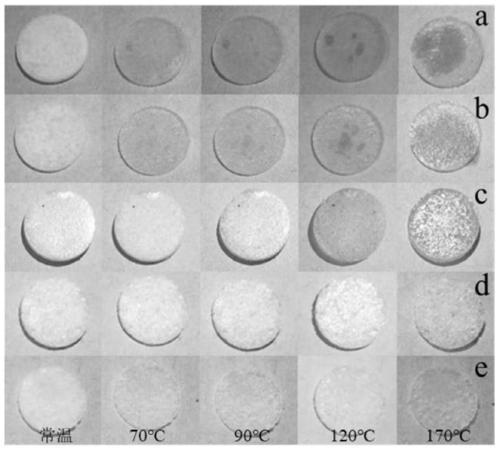

[0041] Preparation of specific embodiment 1 PEG6000 / CDA composite shaped phase-change material particles

[0042] Slowly add 10 g of CDA acetone solution dropwise into 40 g of PEG6000 acetone solution, and stir in a sealed water bath at 40°C for 6 hours; Drying in an oven at ℃ for 12 hours; pulverizing, pressing into tablets, passing through a 20-40 mesh sieve after crushing, to obtain 20-40 mesh granules of cellulose diacetate composite shaped phase change material.

[0043] Application of PEG6000 / CDA composite shaped phase change material particles: put 20-40 mesh sample particles into iQOS cigarettes, and take 5 cigarettes and put them into Y450AKC01 type draw resistance sorter to measure the average draw resistance. The heat-not-burn cigarettes loaded with phase-change particles were placed in the S45000601 smoking machine for simulated smoking test, and the temperature of the filter tip was measured and recorded with a thermocouple. 20-40 mesh PEG6000 / CDA composite shape...

specific Embodiment 2P

[0044] Preparation of Specific Example 2 PEG4000 / CDA Composite Shaped Phase Change Material Particles

[0045] Slowly add 15g of CDA acetone solution dropwise to 35g PEG4000 acetone solution, and stir in a sealed water bath at 40°C for 6h; drying in an oven for 12 hours; pulverizing, pressing into tablets, and passing through a 10-20 mesh sieve after crushing to obtain 10-20 mesh granules of cellulose diacetate composite shaped phase change material.

[0046] Application of PEG4000 / CDA composite shaped phase change material particles: the test method is the same as in Example 1; 10-20 mesh PEG4000 / CDA composite shaped phase change material particles can heat the temperature of the first smoke at the filter end from the control sample iQOS without burning The temperature of the cigarette product dropped from 54°C to 41°C, and the draw resistance was 0.55kPa. The cooling effect of the first 8 puffs was significantly better than that of the iQOS blank sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com