Dry-wet-combining multi-stage dust removing device for mine

A dust removal device and dry dust removal technology, applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of inability to effectively improve dust removal efficiency, mine dust endangering the health of miners, poor adaptability to underground environments, etc., and achieve simple structure and dust removal The effect is good, and the effect of avoiding explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

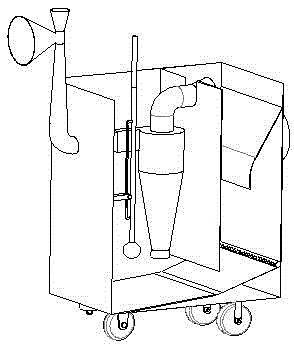

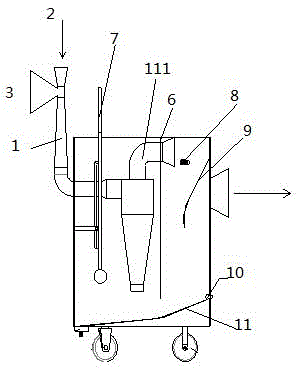

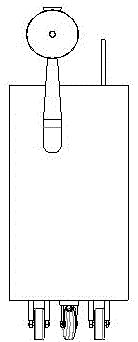

[0026] The dry-wet combined multi-stage dust removal device for mine includes a Venturi tube dust collection mechanism placed outside the dust removal box, a first-stage dry dust removal mechanism, and a second-stage wet dust removal mechanism placed inside the box. When the high-speed air flow is passed through the inlet of the Venturi tube, its speed will be accelerated to the maximum at the throat, and a huge pressure drop will be formed here. Using this pressure drop and cooperating with the dust collection hood, the external mineral dust can be sucked in into the dust collector. After the mine dust enters the interior of the device, it first enters the optimized cyclone dust collector for primary treatment. The optimized cyclone dust collector uses centrifugal force to separate the larger-sized ore dust, and the separated ore dust particles fall from the lower ash-falling circular straight pipe. Using centrifugal force to separate mineral dust can reduce the workload of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com